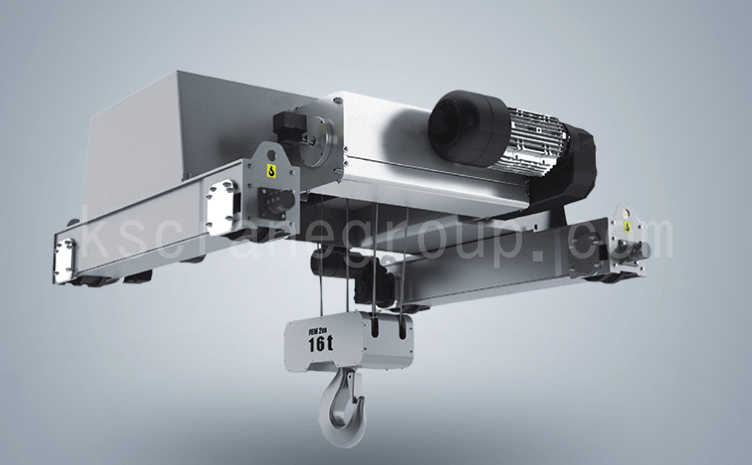

先进的洁净室起重机,适用于 GMP 车间的精确、安全搬运

洁净室起重机是专门为在洁净室内搬运重物时防止产生粉尘而设计的一种设备,通常用于GMP车间。无尘起重机的工作环境一般要求洁净度较高,几乎无尘,内部一般为白色。洁净室专用起重机一般按洁净度等级分为百级、千级、万级、十万级,百级要求洁净度较高,十万级要求洁净度相对较低。

洁净室起重机应用:

洁净室起重机集技术、施工、设备自动化等技术于一体,主要满足化工起重、军工起重、航空航天起重、电子设备起重、制药、生物技术、医疗、实验室等领域对生产环境和质量的严格要求。与其他行业使用的起重机相比,洁净室起重机的主要特点是洁净、耐磨、故障率低、调速范围广、定位准确。因此,洁净室起重机是液晶面板、光伏、微电子、半导体、食品、制药等对环境要求高的行业实现量产的必备设备。

案例:洁净防爆桥式起重机

洁净防爆全自动桥式起重机 为江苏新华半导体材料科技股份有限公司半导体级多晶硅项目研制生产的起重机,满足生产工艺要求,能自动将还原炉及硅棒工具从还原炉平台、清洗平台、转运平台、取出棒工具等工位之间按设定的作业路线运行,准确定位。采用高密封防爆驱动机构、免维护自润滑型轴承等先进技术。集电机、减速机、制动器、电气监控于一体,结构紧凑。

该起重机是为满足新生产工艺而研制的一种具有自动化、洁净化、防爆功能的起重机。使用环境为半导体材料车间,无尘设计,空气洁净度4级(国家标准7级)(即每立方米不超过10000个0.1μm粒径的颗粒)。同时车间内还有易燃易爆气体,起重机防爆等级为dIICT4。

该起重机采用轻量化、免维护设计,大量采用防静电、耐磨、耐腐蚀材料,车轮采用不锈钢材质,轨道两侧有不锈钢凹槽,减速机采用全封闭式,高密封性无漏油污染,高防护等级无风扇防爆电机,双密封制动器可有效防止电机传动磨损产生污染颗粒外泄。整车车轮组采用全封闭式,不锈钢车轮等部位采用高防锈表面处理,可有效防止金属材料生锈污染,自润滑密封轴承,避免润滑污染。

产品特性

1.清洁除尘

采用高压防静电喷涂技术,结构密封焊接技术,使整机具有不粘尘,不产尘的特点。粉尘颗粒及润滑油污物,自动通过永磁机械、防爆电动集尘器、机械集油盘等装置实现清理工作。超低噪音的环境体验。

2.安全防爆

在洁净、智能的前提下,安全防爆功能再添亮点,在任何空间内的动作均处于防爆状态,使起重机运行更加安全可靠。

3.智能操作

具有全自动无人操作、防摆自动精确定位、自动卸钩等功能,定位精度可达到毫米以内。

4.功能无人化

具有故障自动报警、自动检测故障原因、零件寿命设定报警等人性化功能。

大小车运行机构采用激光条码定位,小车激光条码定位阅读器安装在小车上,条码带安装在大车主梁腹板上,大车定位激光定位阅读器安装在端梁上,条码带安装在收集粉屑的U型槽上。

行走控制有两种操作模式:

1.自动运行方式:

现场工作人员需要进行起吊操作时,通过防爆遥控器操纵现场将手动吊钩挂到吊具上,完成后通过防爆遥控器选择相应的功能,完成后通过声光报警提示开始操作。操作的关键点由现场操作人员用防爆遥控器确认后,起重机按照预先设定的路径自动运行到目标位置正上方进行还原炉的起吊或卸料杆具的动作,动作完成后,报警并提示动作已完成。

在运行过程中,若发现问题,可选择暂停,待问题消除后,按继续键可继续执行。如遇紧急故障,可选择遥控器紧急停止键,停止设备运行,避免故障发生。

2.手动操作模式

将防爆控制柜选择开关旋至‘手动’控制方式,现场工作人员可通过防爆按钮现场手动操作起重机,控制各机构的手动操作。遥控与手柄控制互锁,同一时间只能采用一种控制方式。

其他类型的洁净室起重机

联系我们

- 产品的免费和快速报价。

- 为您提供我们的产品目录。

- 您当地的起重机项目来自我们公司。

- 成为我们的代理并赚取佣金。

- 有任何问题,请联系我们。