- EQUIPMENT

- special cranes

- Industry Crane

- Hoist & Winch Trolley

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

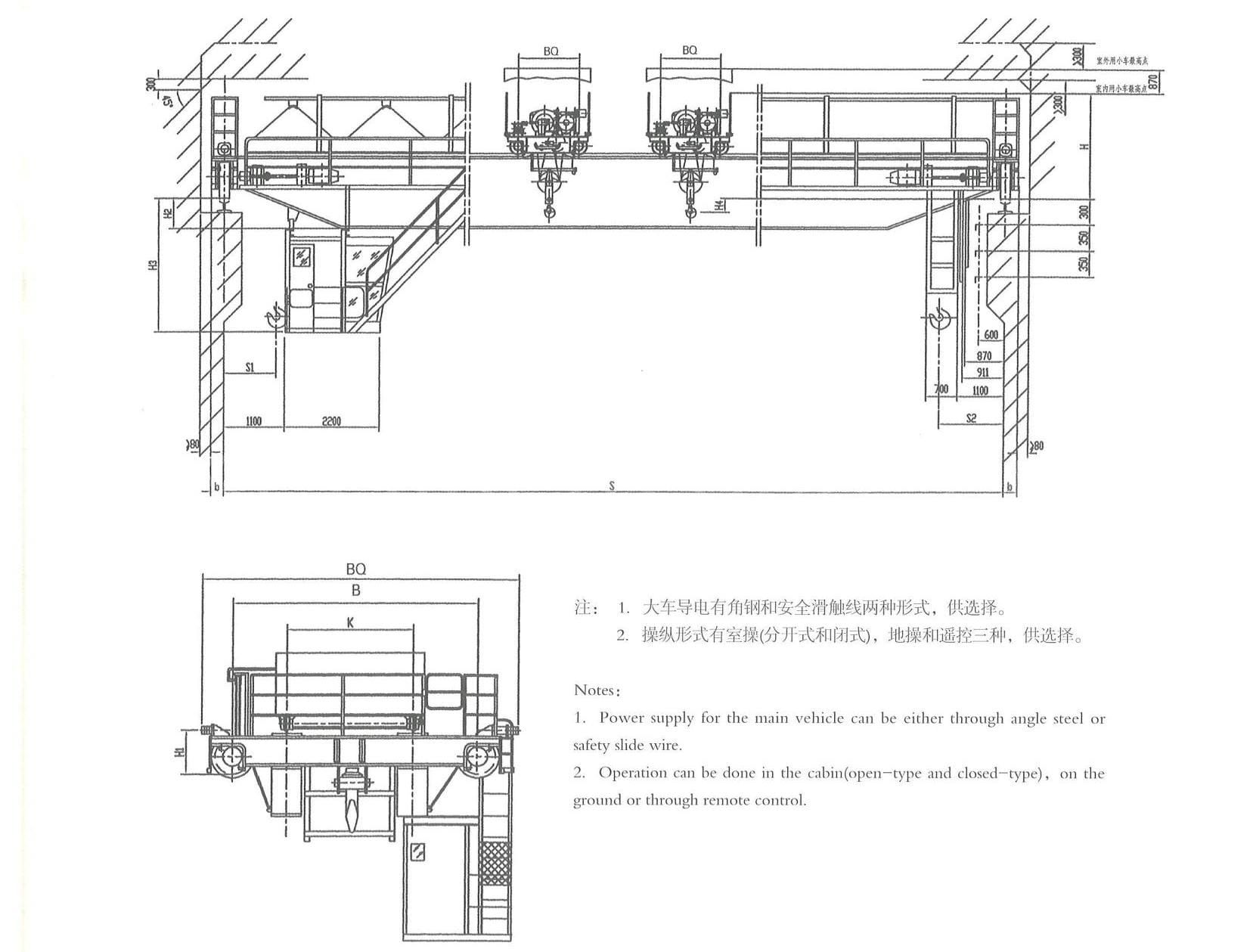

QE Double Trolley Overhead Crane – Tandem Hoist for Long Loads

This QE double trolley overhead crane features two trolleys, that can be used simultaneously or independently. It is suitable for lifting long materials (such as lumber, paper tubes, pipes, and rods) in workshops or open-air warehouses of industrial and mining enterprises. When lifting long items, synchronous hoisting and operation can be achieved through the switch on the control console. High-capacity options can be customized according to customer requirements.

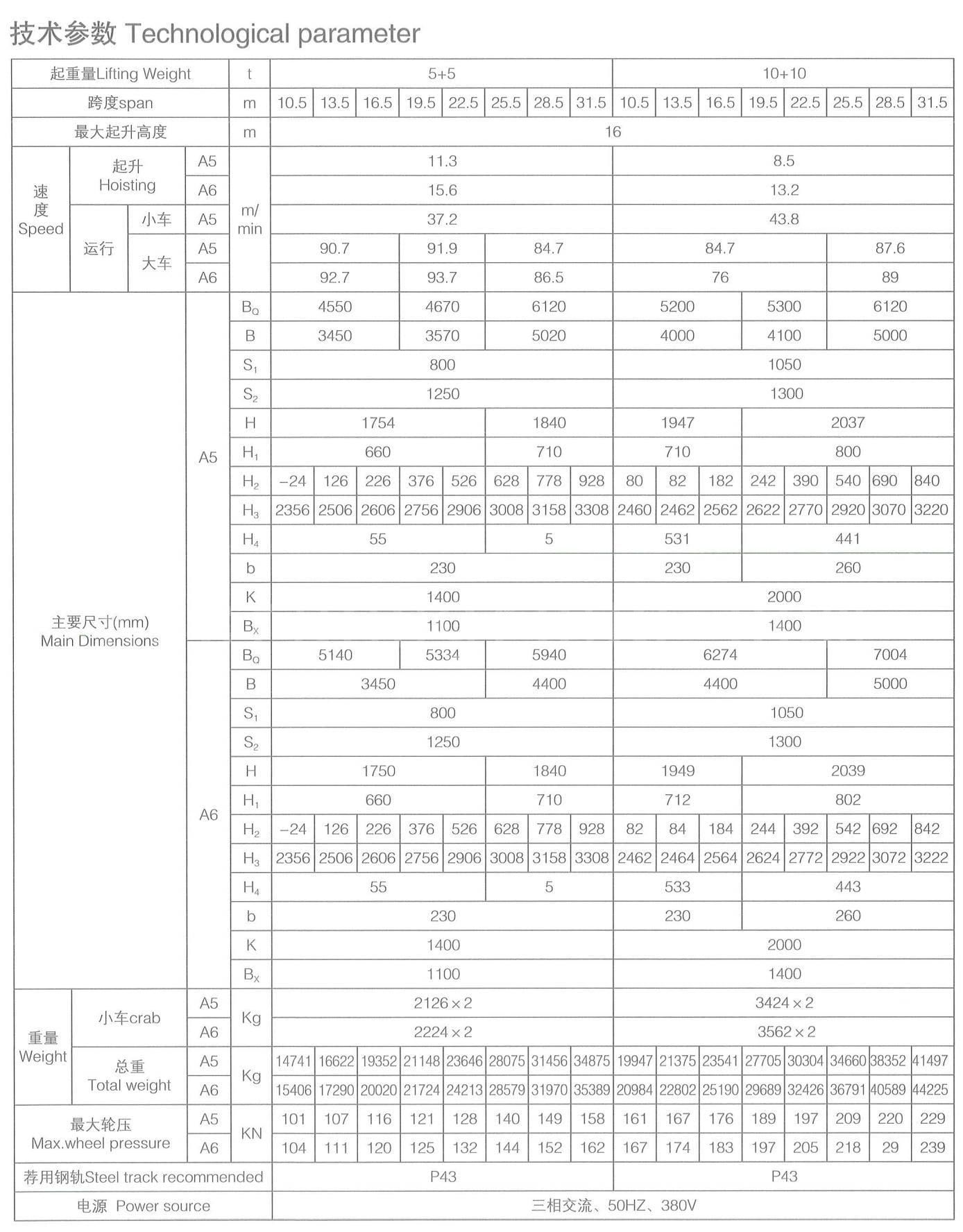

Specification

Cases with prices

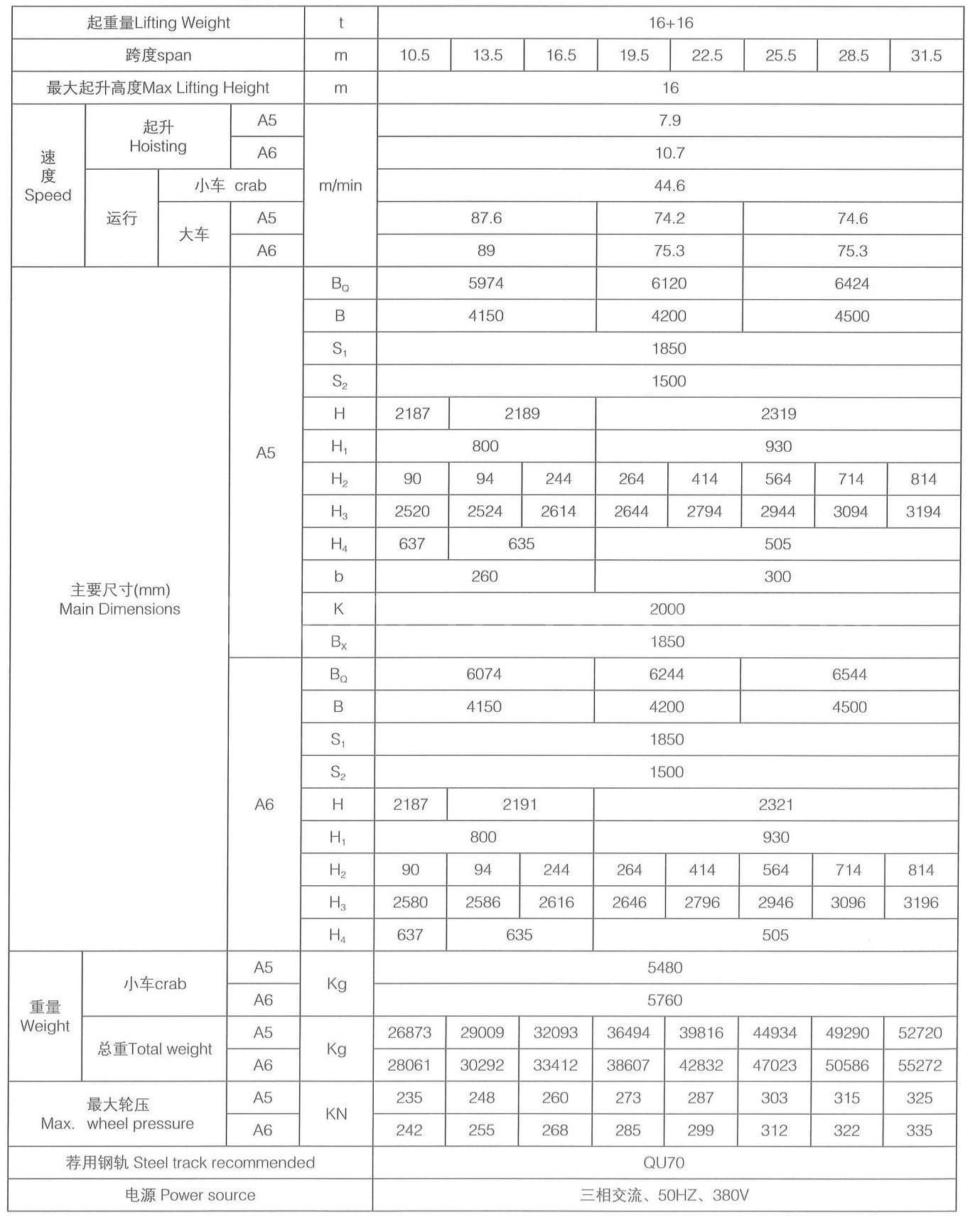

- Type: QE double trolley overhead crane

- Capacity: 10 ton+5 ton

- Span: 14.05 m

- Lifting height: 12m (main trolley), 12m (auxiliary trolley)

- Lifting speed: 0.63-6.3 m/min (main trolley), 0.63-6.3 m/min (auxiliary trolley)

- Traveling speed: 1.9-19m/min (crane), 1.4-14 m/min (main trolley), 1.4-14 m/min (auxiliary trolley)

- Working Duty: A5

- Control Method: Ground control + remote control

- Price: 468,000 RMB

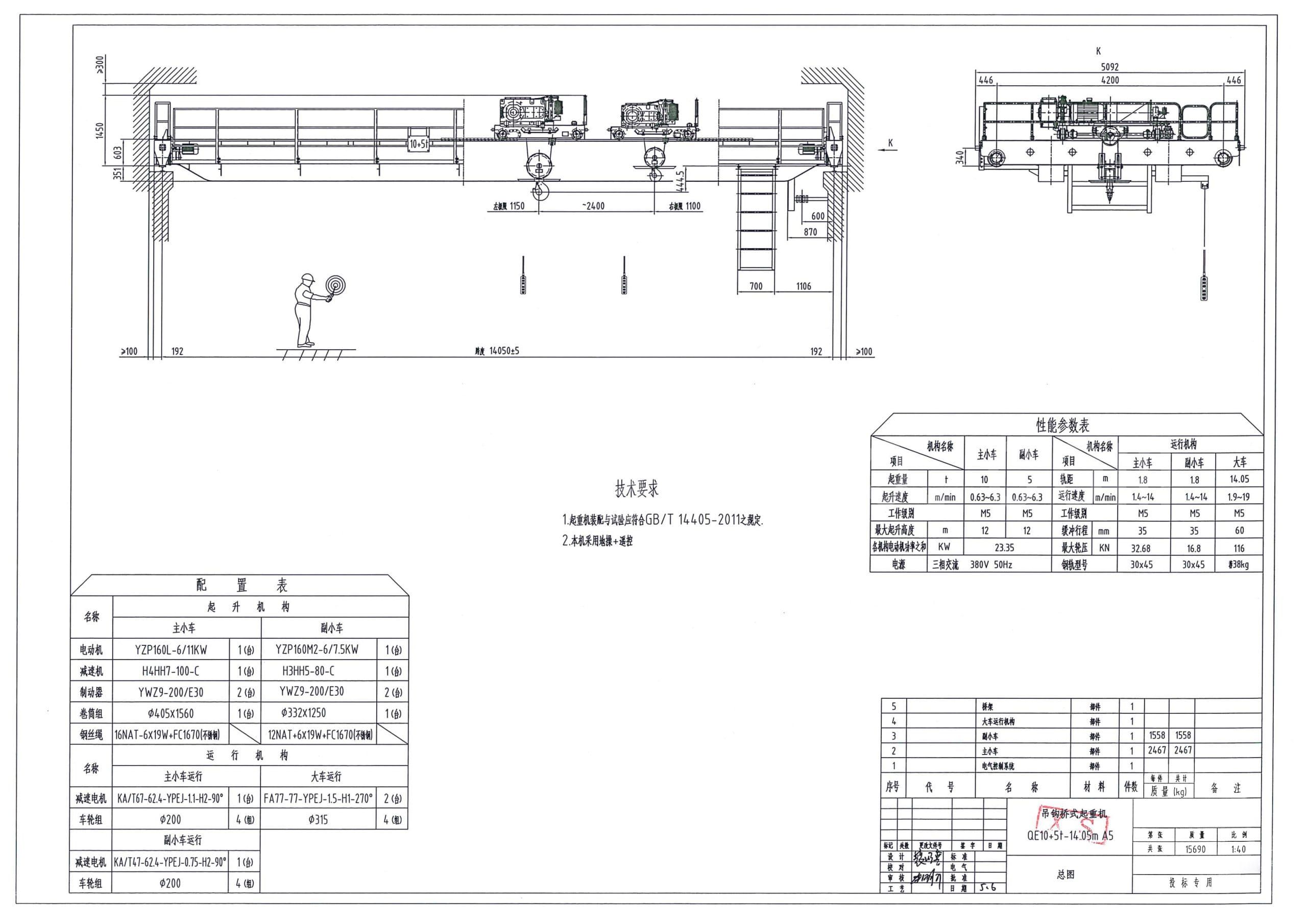

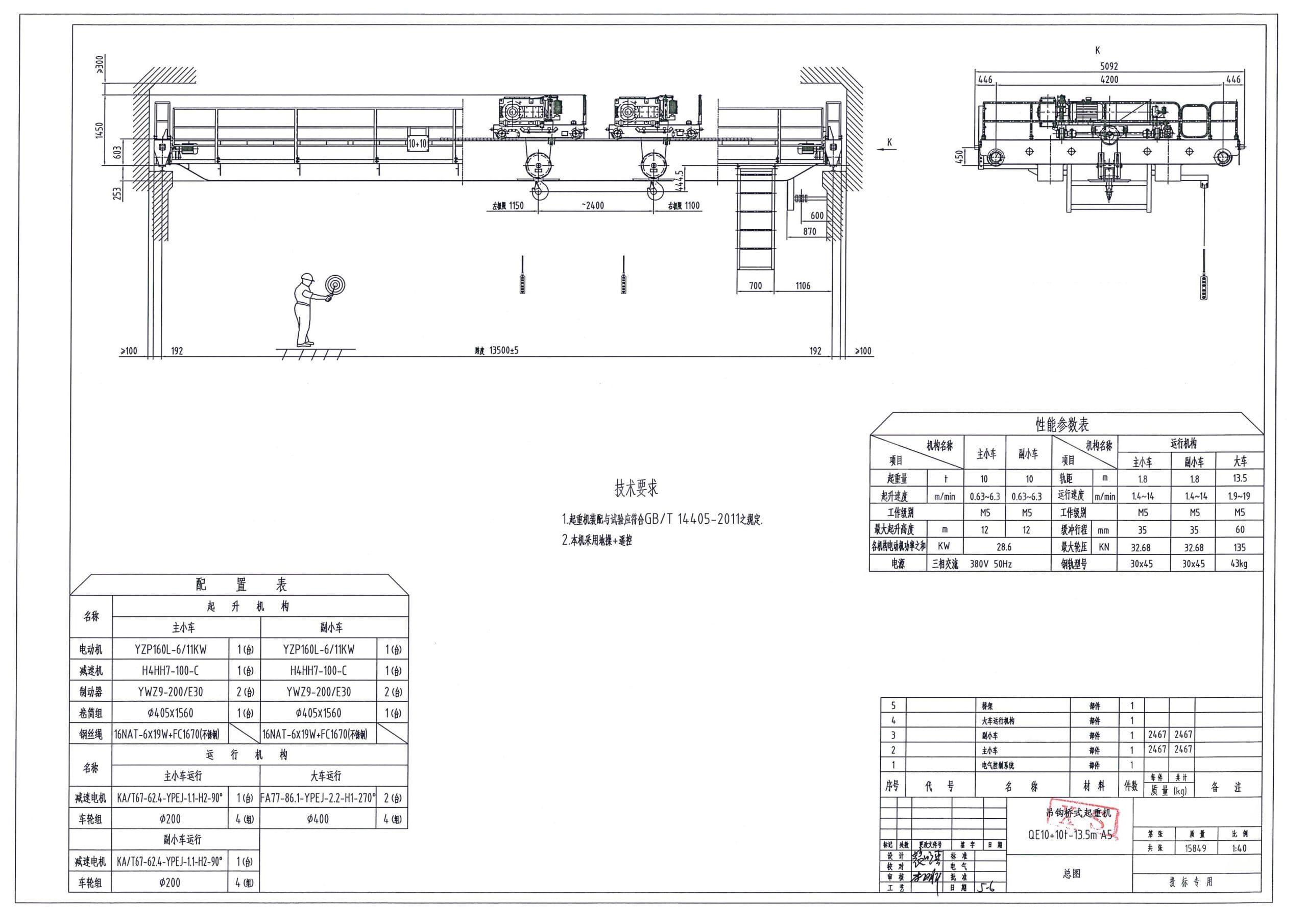

- Type: QE double trolley overhead crane

- Capacity: 10 ton+10 ton

- Span: 13.5 m

- Lifting height: 12m (main trolley), 12m (auxiliary trolley)

- Lifting speed: 0.63-6.3 m/min (main trolley), 0.63-6.3 m/min (auxiliary trolley)

- Traveling speed: 1.9-19m/min (crane), 1.4-14 m/min (main trolley), 1.4-14 m/min (auxiliary trolley)

- Working Duty: A5

- Control Method: Ground control + remote control

- Price: 500,000 RMB

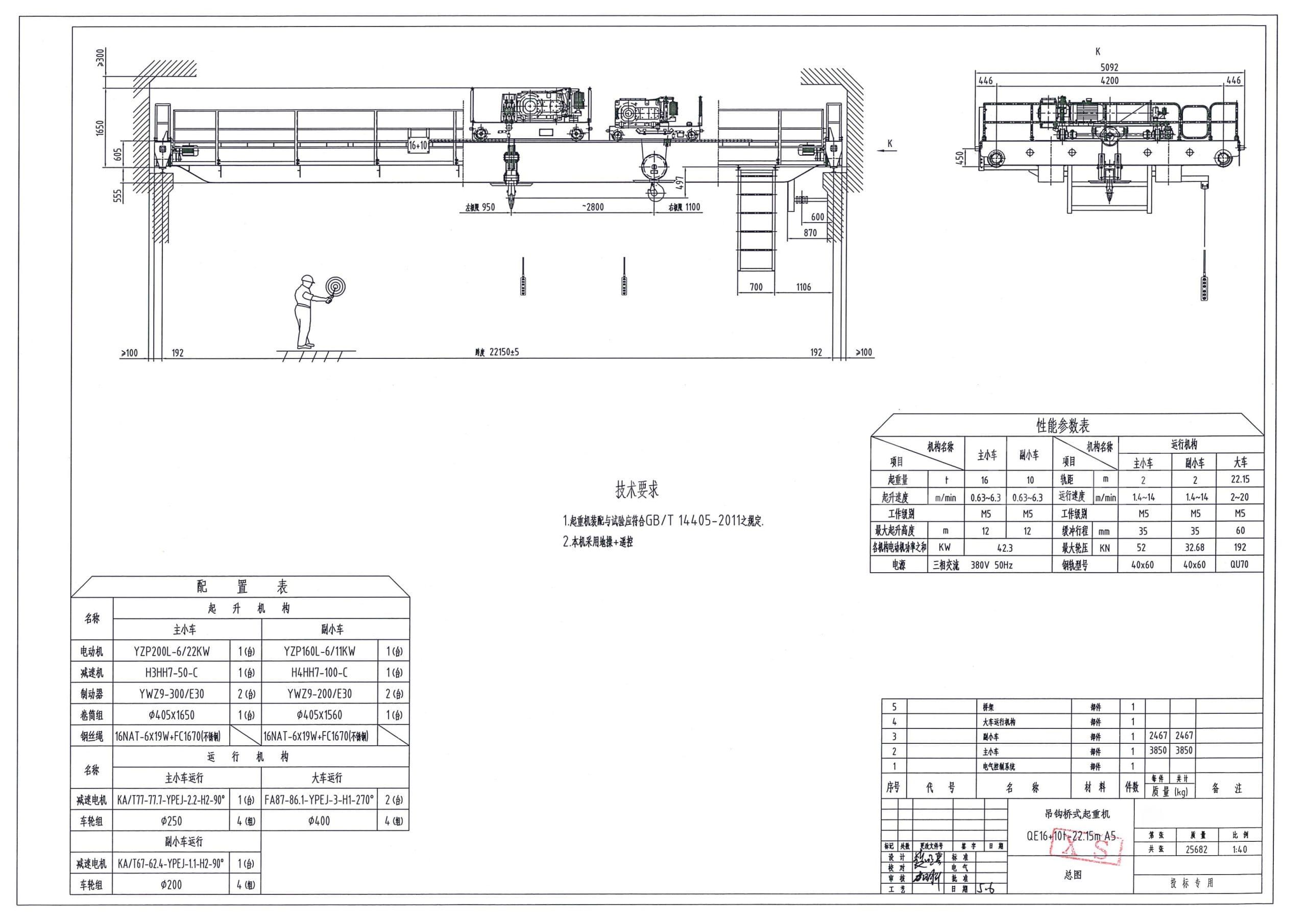

- Type: QE double trolley overhead crane

- Capacity: 16 ton+10 ton

- Span: 22.15 m

- Lifting height: 12m (main trolley), 12m (auxiliary trolley)

- Lifting speed: 0.63-6.3 m/min (main trolley), 0.63-6.3 m/min (auxiliary trolley)

- Traveling speed: 2-20 m/min (crane), 1.4-14 m/min (main trolley), 1.4-14 m/min (auxiliary trolley)

- Working Duty: A5

- Control Method: Ground control + remote control

- Price: 620,000 RMB

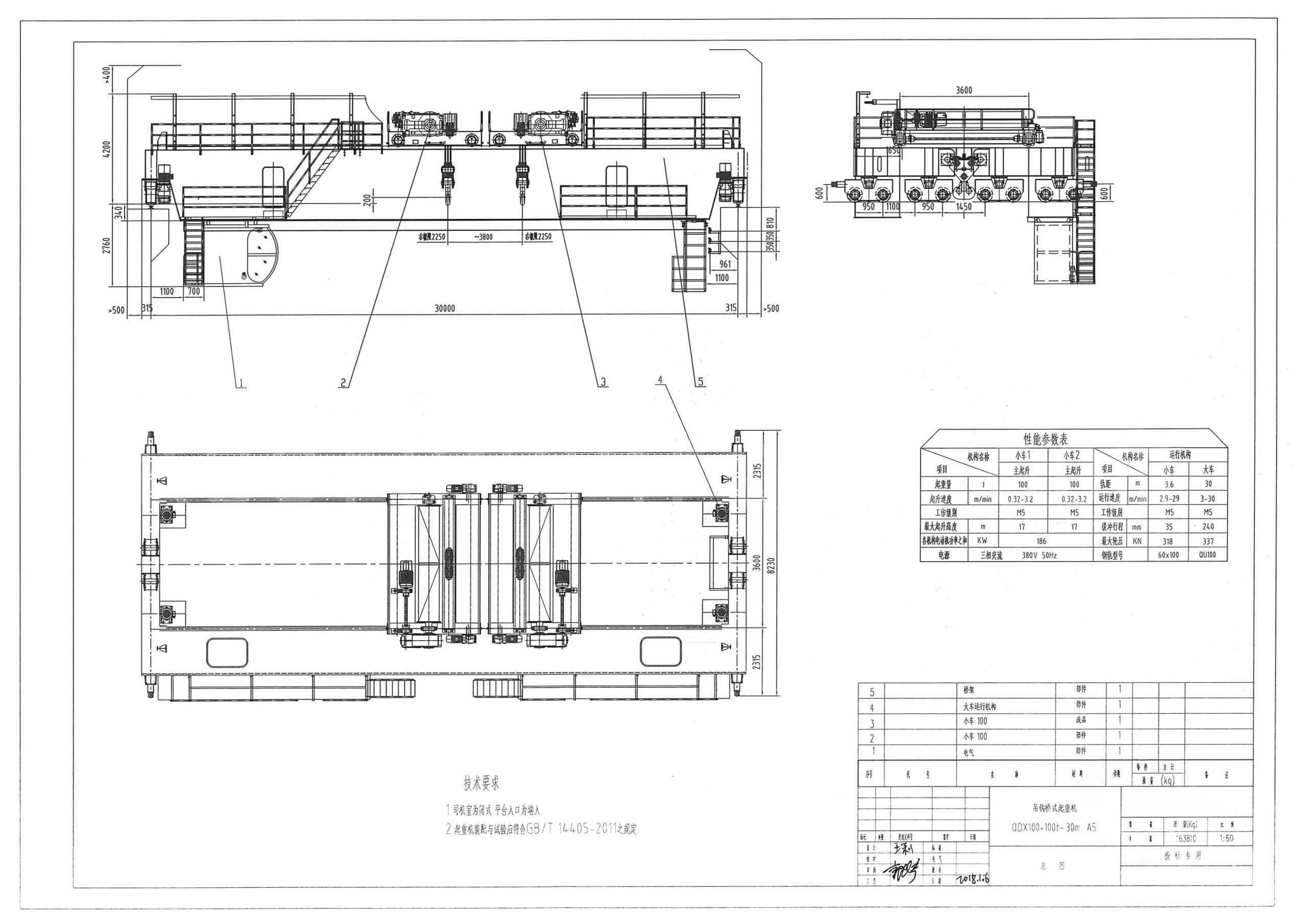

- Type: QE double trolley overhead crane

- Capacity: 100 ton+100 ton

- Span: 30m

- Lifting height: 17m (main trolley), 17m (auxiliary trolley)

- Lifting speed: 0.32-3.2m/min (main trolley), 0.32-3.2 m/min (auxiliary trolley)

- Traveling speed: 3-30 m/min (crane), 2.9-29 m/min (trolley)

- Working Duty: A5

- Control Method: Cabin control + remote control

- Price: 2,315,300 RMB

Services

Kuangshan Crane has over 20 years of extensive experience manufacturing and exporting double trolley overhead cranes. It offers necessary spare parts and professional installation and maintenance guidance services for all double trolley overhead cranes.

- Spare Parts

We will prepare the required spare parts for your double trolley overhead crane so that any damaged or lost parts can be promptly replaced, reducing maintenance downtime and improving production efficiency. - Installation

We provide detailed video installation procedures, and if needed, we can also offer remote video guidance. - Maintenance

We provide detailed maintenance instructions and offer free consultation services for any issues arising during the crane’s usage period.

Henan Kuangshan Crane

The drawings used by Henan Kuangshan Crane Co., Ltd. are all the latest designs based on orders and are optimized through computer-aided design, resulting in a more reasonable structure. All drawing designs comply with the latest national standards aligned with international standards, representing the latest structural design and advanced level of domestic lifting products. Henan Kuangshan’s production equipment is advanced, and its inspection equipment is comprehensive, ensuring the quality of the cranes in every aspect.

Production Equipment

The plan includes the installation of 22 intelligent production lines, with automation levels reaching over 85% throughout the entire production process.

Inspection Equipment

We have a robust product quality assurance system, a comprehensive quality inspection department, and qualified quality control personnel. We possess over 100 various inspection and testing instruments and experimental devices, some of which are at the leading level domestically and advanced internationally.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.