- EQUIPMENT

- special cranes

- Industry Crane

- Hoist & Winch Trolley

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Reliable QC Electromagnetic Overhead Cranes for Scrap Metal Handling

The basic structure of the QC electromagnetic overhead crane is the same as that of the overhead crane with a lifting hook, with the key difference being that a DC lifting electromagnet is attached to the hook for lifting ferromagnetic metals and their products. An SCR DC box installed in the operator’s cabin converts the AC power supply to DC power, which is then transmitted via a special cable reel mounted on the trolley to the electromagnet.

Specification

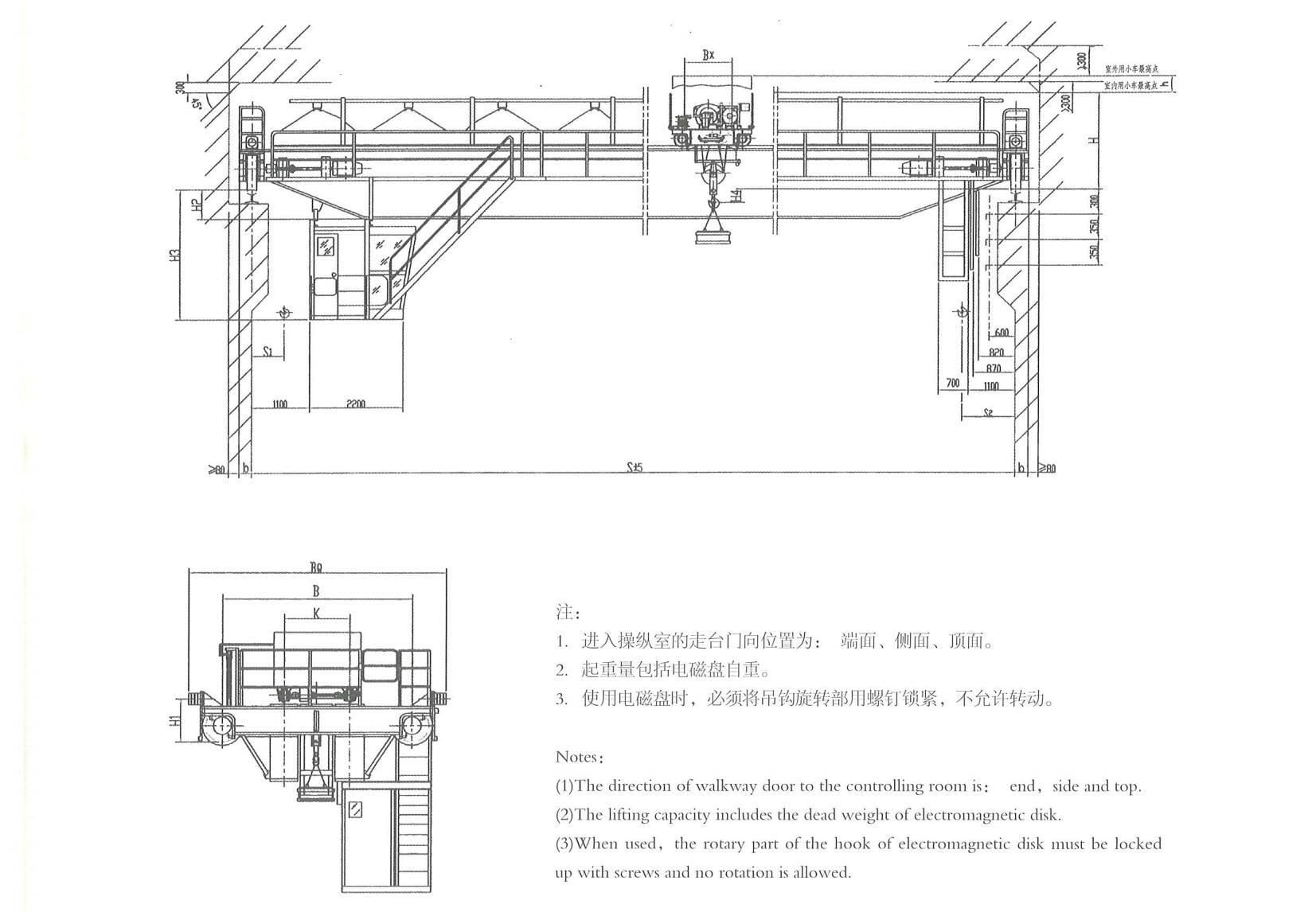

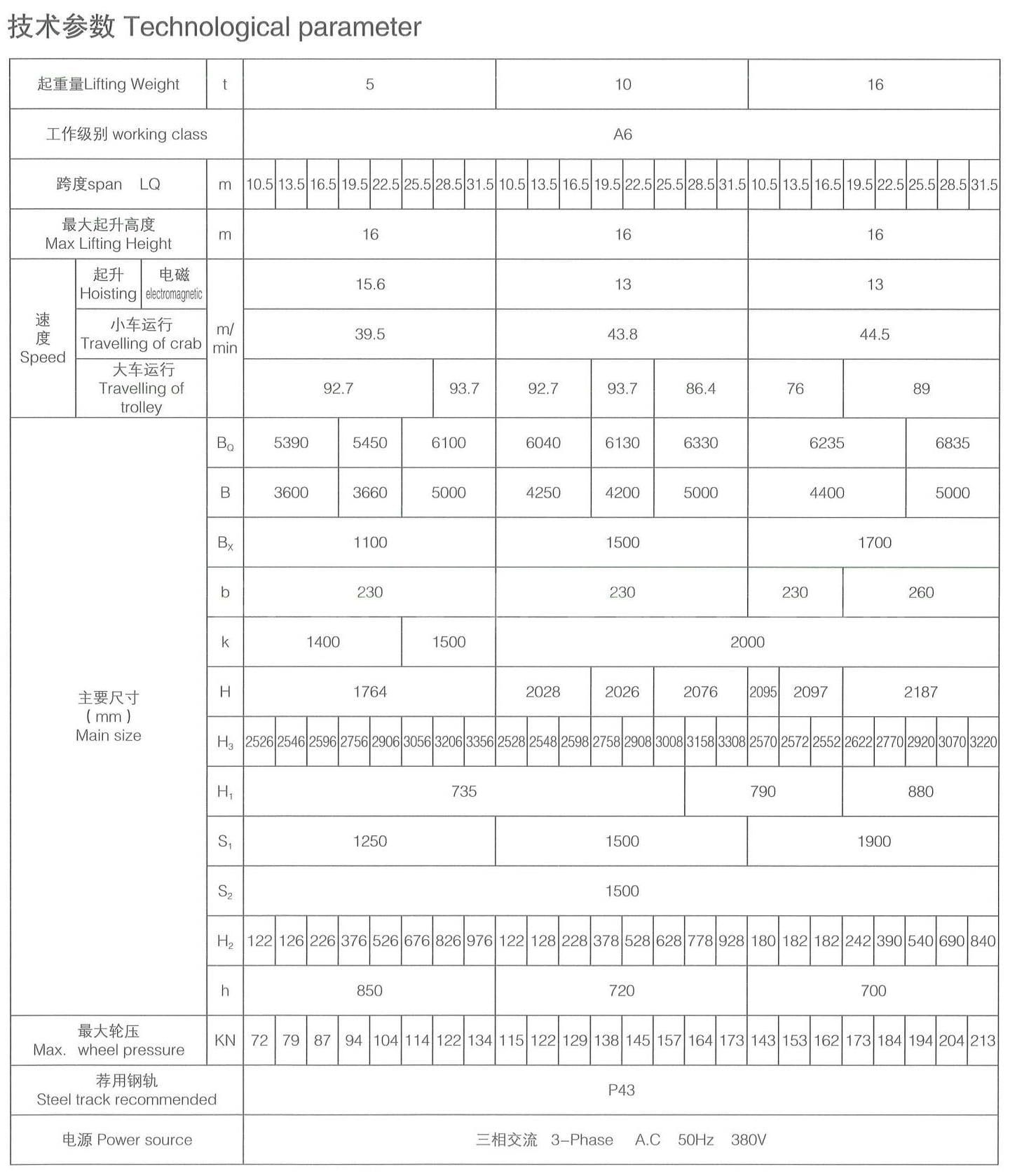

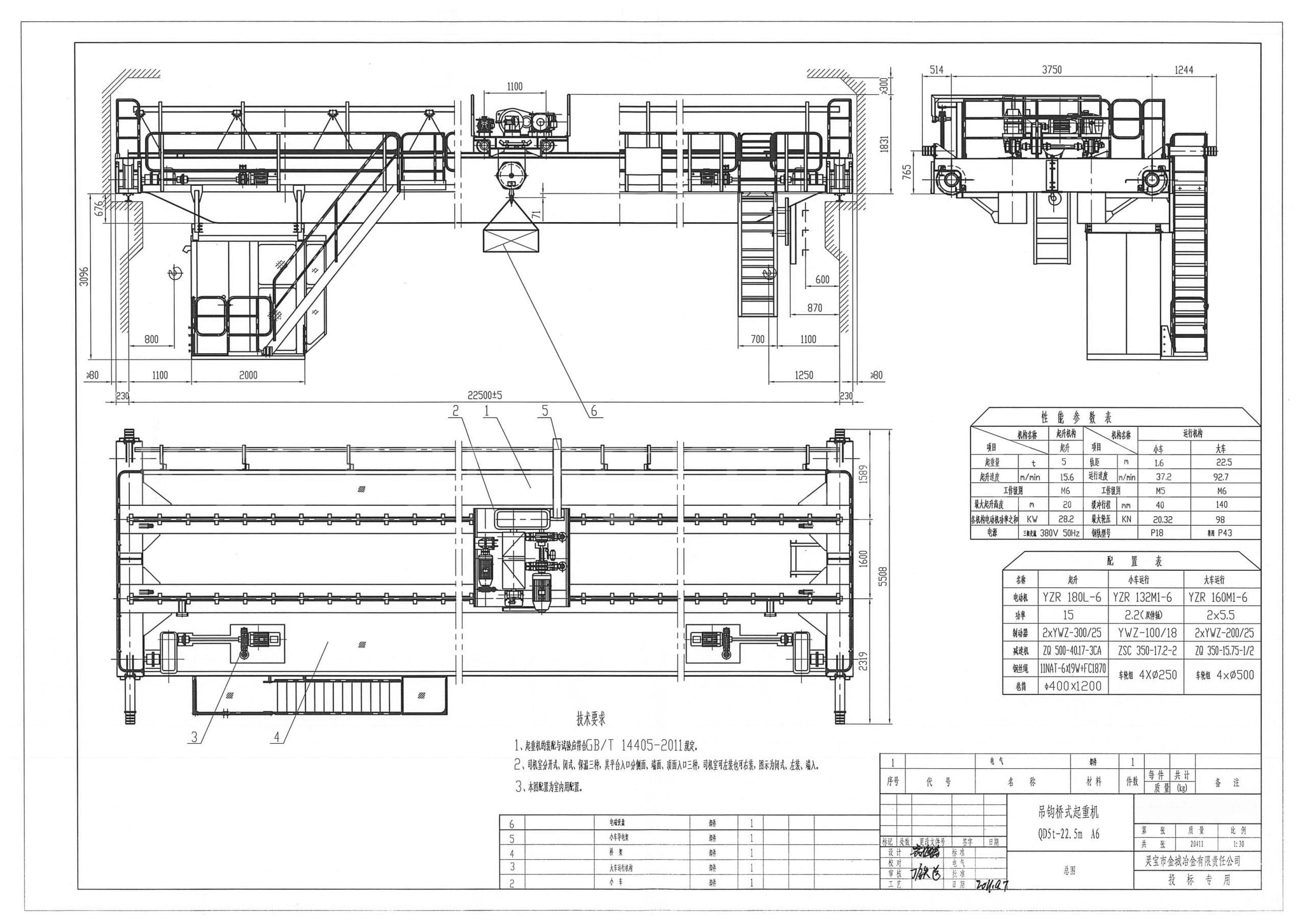

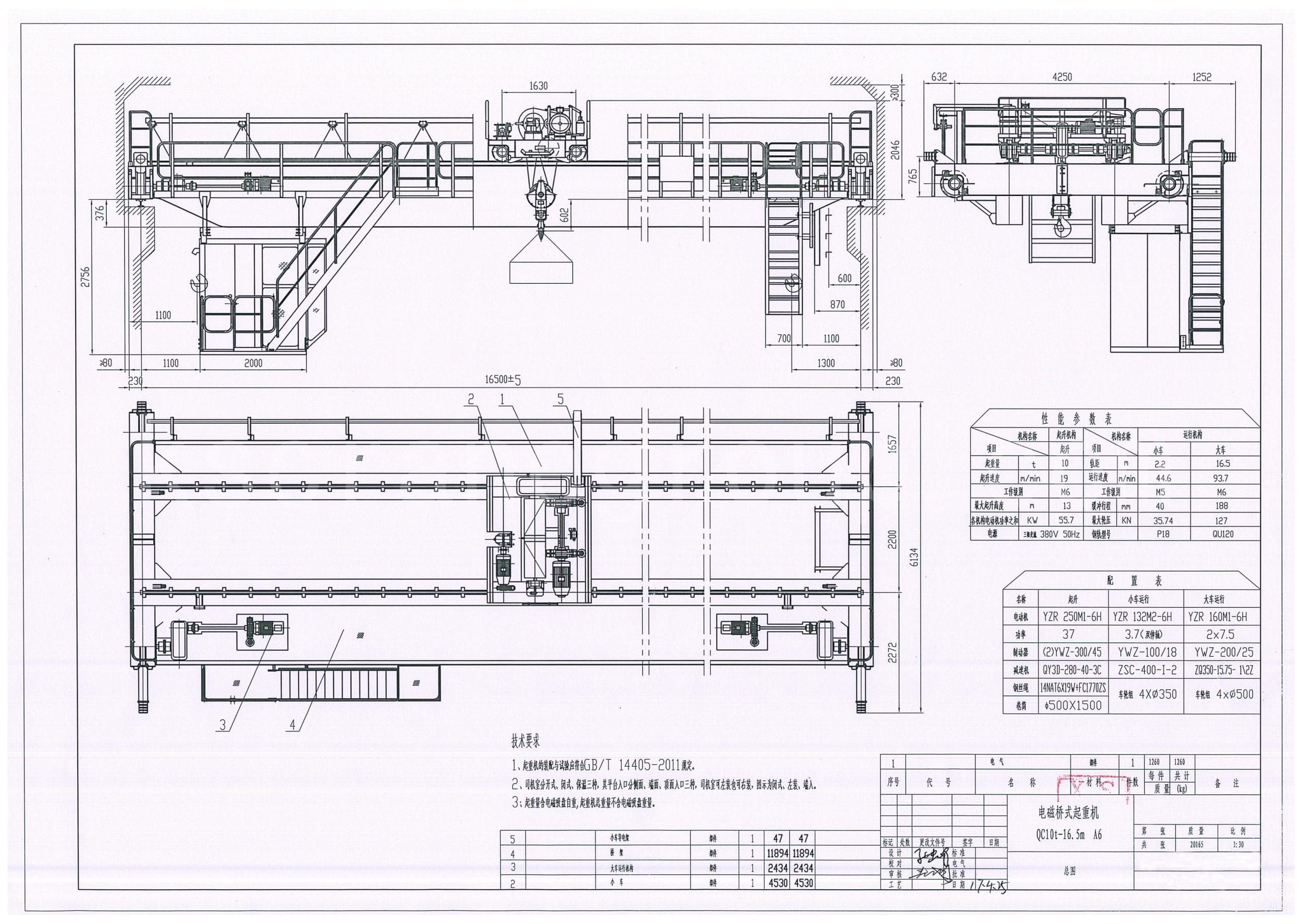

5-16 Ton electromagnetic overhead cranes diagram and parameter

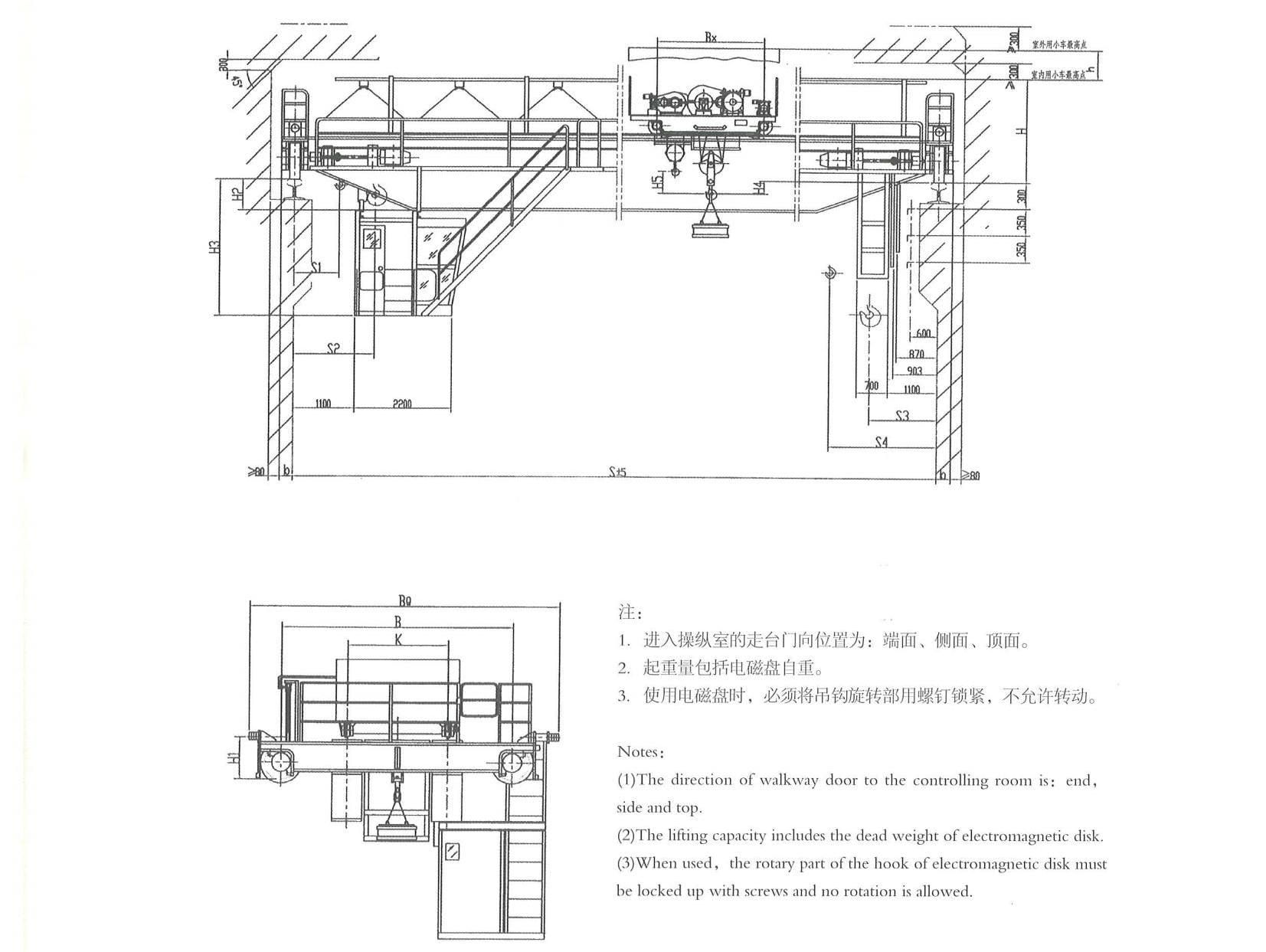

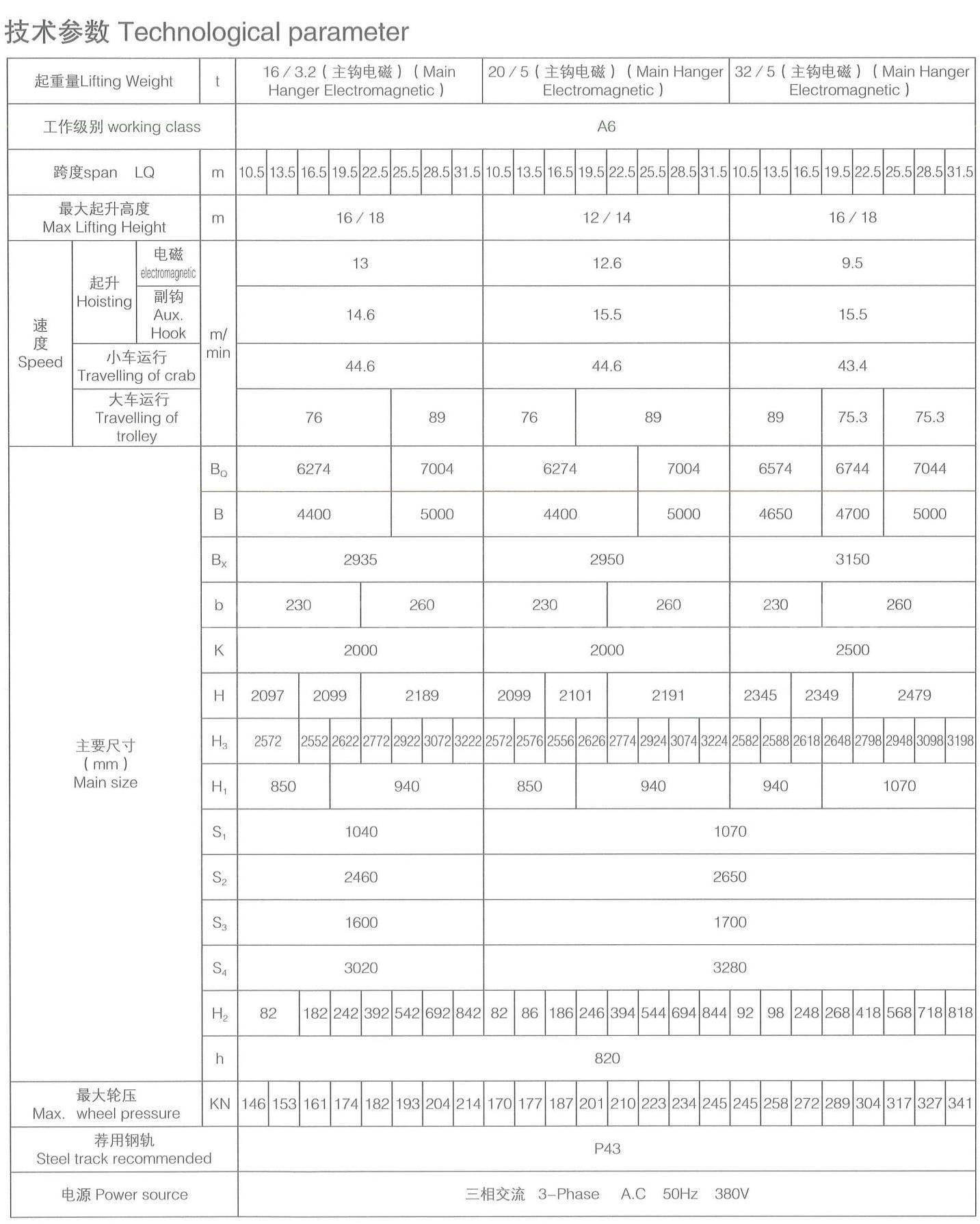

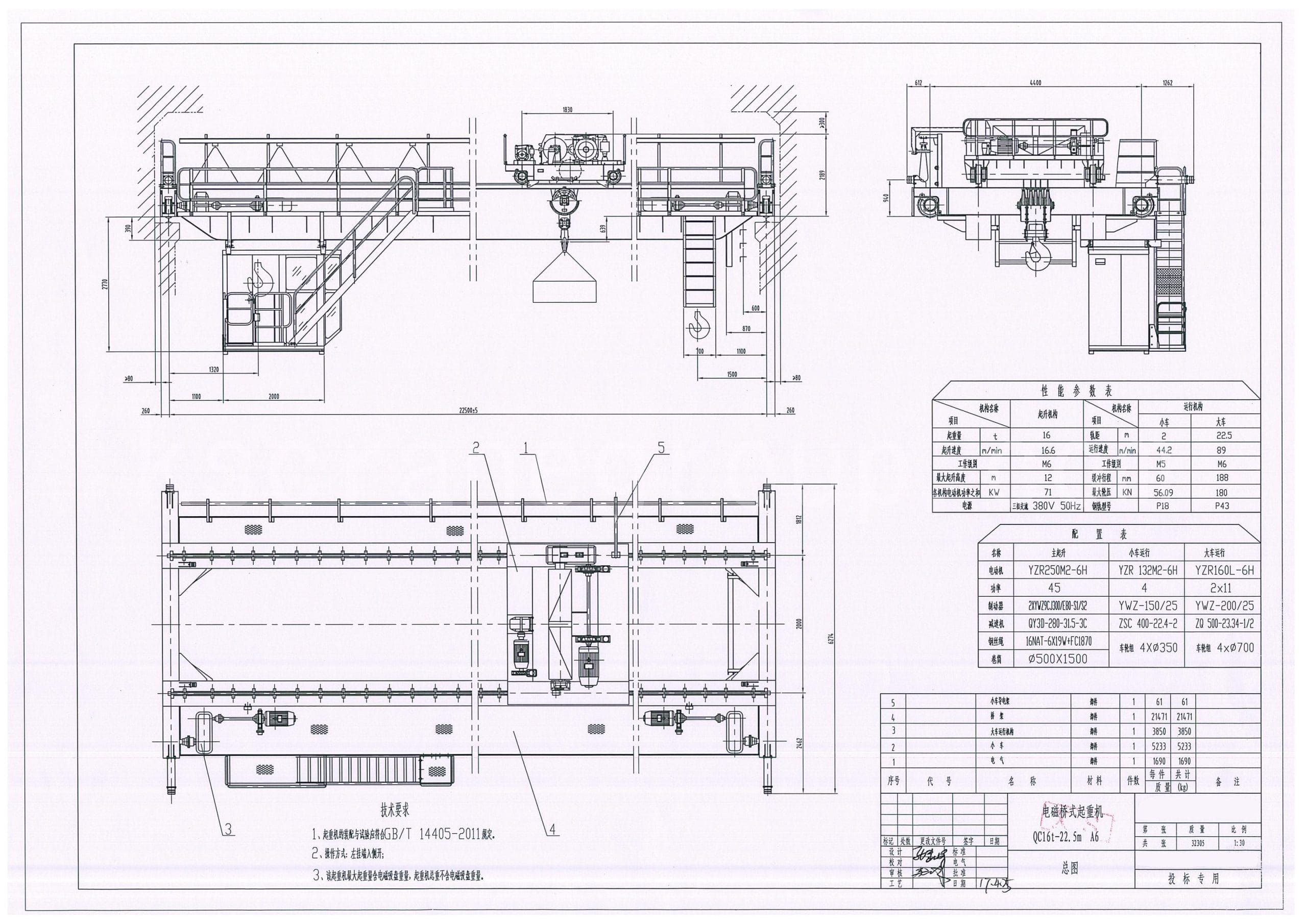

16/3.2-32/5 Ton electromagnetic overhead cranes diagram and parameter

Cases with prices

Product Parameters

- Type: Electromagnetic overhead cranes

- Capacity: 5 ton

- Span: 22.5 m

- Lifting height: 20 m

- Lifting speed: 15.6 m/min

- Traveling speed: 92.7 m/min (crane), 37.2 m/min (trolley)

- Working Duty: A6

- Control Method: Cabin control

- Price: 233,042 RMB

Product Parameters

- Type: Electromagnetic overhead cranes

- Capacity: 10 ton

- Span: 16.5 m

- Lifting height: 13 m

- Lifting speed: 19 m/min

- Traveling speed: 93.7 m/min (crane), 44.6 m/min (trolley)

- Working Duty: A6

- Control Method: Cabin control

- Price: 244,900 RMB

Product Parameters

- Type: Electromagnetic overhead cranes

- Capacity: 16 ton

- Span: 22.5 m

- Lifting height: 12 m

- Lifting speed: 16.6 m/min

- Traveling speed: 89 m/min (crane), 44.2 m/min (trolley)

- Working Duty: A6

- Control Method: Cabin control

- Price: 308,600 RMB

Lifting magnets

In addition to the round electromagnetic lifter, the electromagnetic bridge crane can also be equipped with rectangular and oval electromagnetic lifters. The different shapes of electromagnetic lifters are suited to various materials and application scenarios.

Round lifting magnet: Suitable for lifting cast iron ingots, steel balls, pig iron blocks, machining scraps, various scrap iron, furnace return materials, cutting heads in foundries, and bundled scrap steel. It is also used in slag handling processes to initially remove large iron pieces and lift iron powder in coal washing plants.

Rectangular lifting magnet: Primarily suitable for lifting steel coils, billets, ingots, and large rough slabs, it can also be used for lifting round billets, structural steel, and other similar materials. Different magnetic circuit designs are employed for various types of steel.

Oval lifting magnet: Suitable for efficiently loading and unloading scrap steel in narrow and confined spaces, such as inside small truck beds. These lifting devices are typically custom-made according to the shape and size of the truck bed.

FAQ

- What are the different types of electromagnetic overhead cranes?

This can be structurally classified into electromagnetic overhead cranes and electromagnetic overhead cranes with lifting beams. - What are the advantages of electromagnetic overhead cranes?

The electromagnetic overhead crane offers a fast and efficient solution for all work scenarios requiring steel handling. It can support larger loads, enhancing work efficiency. Additionally, it features higher safety with a power-off magnetic retention function. - Electromagnetic overhead crane how does it work?

They operate using a magnetic field generated by the current passing through the coil around the magnet. When the current is turned on, the electromagnet attracts the steel items, which are then transported to the designated location. The magnetism disappears when the current is turned off, and the steel items are released. - What are the uses of electromagnetic overhead cranes?

Steel recycling stations, steel scrap storage areas, steel mills, foundries, shipyards, steel stockyards, etc.

Services

Kuangshan Crane has over 20 years of extensive experience in manufacturing and exporting electromagnetic overhead cranes, offering necessary spare parts and professional installation and maintenance guidance services for all electromagnetic overhead cranes.

- Spare Parts

We will prepare the required spare parts for your electromagnetic overhead cranes so that any damaged or lost parts can be promptly replaced, reducing maintenance downtime and improving production efficiency. - Installation

We provide detailed video installation procedures, and if needed, we can also offer remote video guidance. - Maintenance

We provide detailed maintenance instructions and offer free consultation services for any issues that may arise during the crane’s usage period.

Henan Kuangshan Crane

The drawings used by Henan Kuangshan Crane Co., Ltd. are all the latest designs based on orders and are optimized through computer-aided design, resulting in a more reasonable structure. All drawing designs comply with the latest national standards aligned with international standards, representing the latest structural design and advanced level of domestic lifting products. Henan Kuangshan’s production equipment is advanced, and its inspection equipment is comprehensive, ensuring the quality of the cranes in every aspect.

Production Equipment

The plan includes the installation of 22 intelligent production lines, with automation levels reaching over 85% throughout the entire production process.

Inspection Equipment

We have a robust product quality assurance system, a comprehensive quality inspection department, and qualified quality control personnel. We possess over 100 various inspection and testing instruments and experimental devices, some of which are at the leading level domestically and advanced internationally.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.