- EQUIPMENT

- special cranes

- Industry Crane

- Hoist & Winch Trolley

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

10 Devastating Electric Hoist Failures: What You Urgently Need to Know

Date: 23 Aug, 2024

Table of Contents

Day long people are always sick, people have a disease that is not terrible, terrible is not to find the cause of the disease, and can not be treated with the right medicine. For the same reason, lifting machinery and people, as long as the day will be a variety of faults, can not find the cause of the failure, will not be able to troubleshoot, so as to cause harm and destruction, equipment damage and casualties in the event of an accident. In this paper, the daily use of an electric hoist failure will often appear in the cause of the is analyzed, and put forward the corresponding methods of treatment.

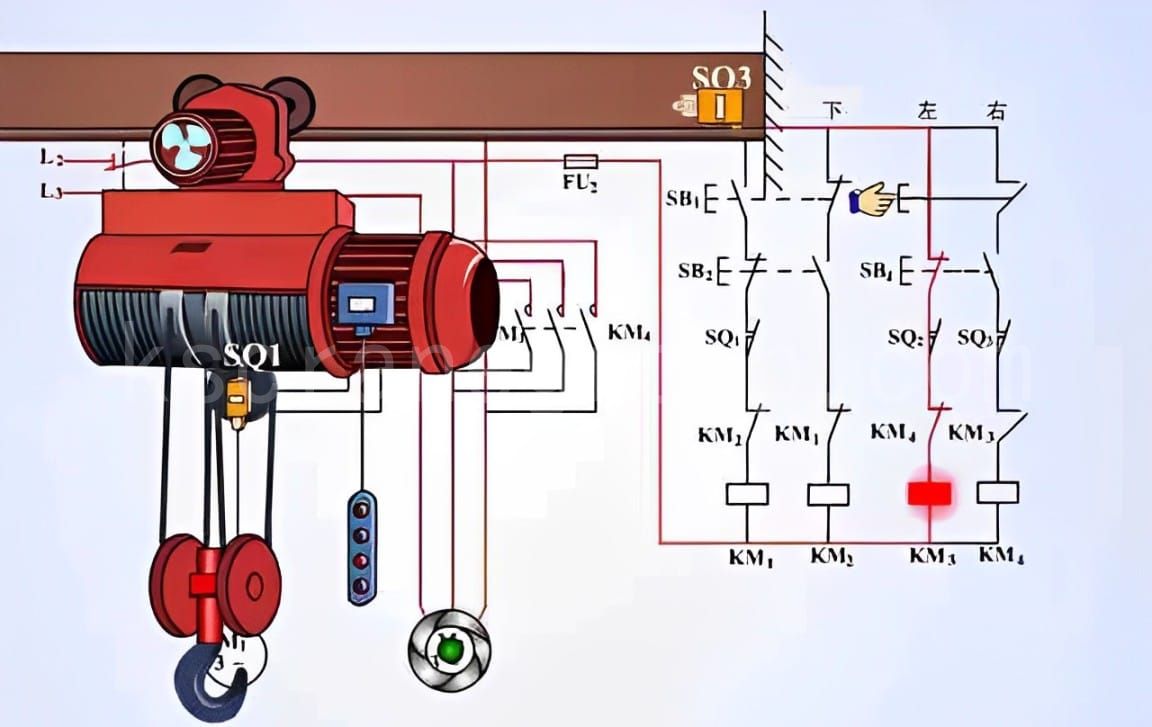

1. Causes of electric hoist failure: the no-load motor can not start

a. The power supply of the motor is not connected, after checking and confirming, immediately connect the power supply.

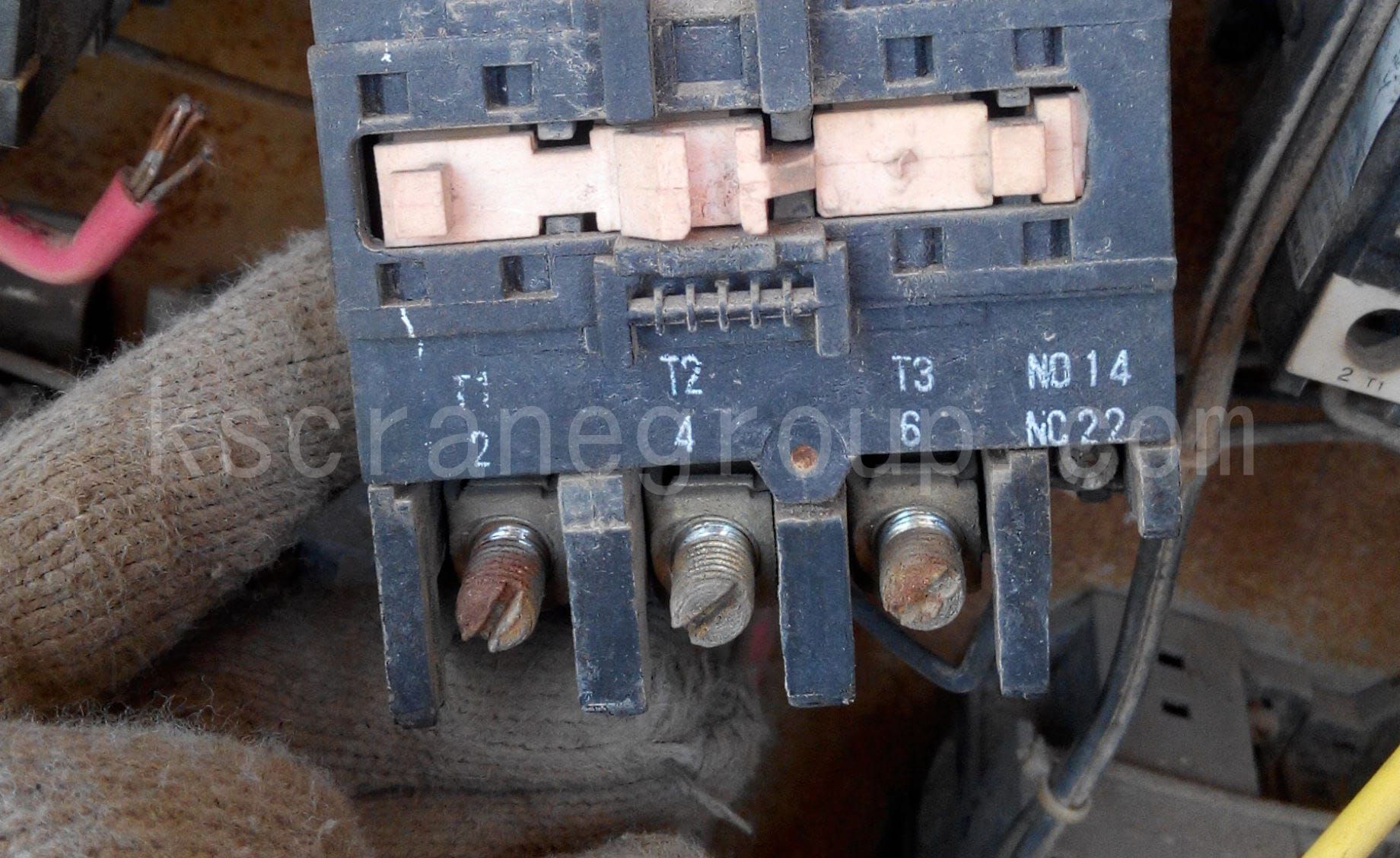

b. Start button failure, poor contact or contact fuses, contactors, and other components are damaged or failed, then we must repair and replace the relevant electrical components.

c. limiters are not reset, start button wiring is broken or off, immediately reset the limiters, and the button wiring is fixed firmly.

2. Causes of electric hoist failure: hand point electric hoist palm switch start button after the hoist did not react

a. When the start button is pressed, there is no “tick” sound, indicating that the electric hoist connected to the power supply does not reach the rated voltage of the electric hoist work or the power supply is not connected. First of all, check whether the power control switch has been closed, through the switch indicator, to determine whether the power supply is connected, and vice versa, not connected.

b. Start button failure or poor contact, to overhaul and replace the relevant components.

c. The power control switch has been closed, and the palm of the switch when pressing the start button | has no “pop” sound, may be the main electric hoist, the control circuit power is not connected. First check whether the line disconnection, poor contact, and electrical damage cause the main control circuit. Before repair, it must be noted that, in order to prevent the power suddenly turned on, the motor rotation accidents, you should first pull down the control power switch of the hoist motor, cut off the power supply, only the main, control circuit power supply, gently tap the start button and the stop button, to check whether it is caused by the line contact, or the power controller problems. Only in the main, control circuit to confirm that there is no obstruction, smooth, before you can try again.

d. The electric hoist motor voltage is lower than the rated voltage hoist work, resulting in the hoist can not work properly, only when the voltage is restored to the rated voltage, before lifting work. Sometimes although the voltage of the motor is to the rated voltage, still can not lift, then we must think of whether the motor is burned, whether the hoist has not been used for a long time, so that the brake wheel and the end cover rusted or motor serious sweeping and other reasons, after checking the situation is true should be overhauling or replacing the new motor to ensure that the lifting work is carried out normally. At the same time, lifting work should be strictly in accordance with the hoist lifting standards lifting heavy objects, in order to prevent damage to the electric hoist accident, prolong the working time. In addition, in the process of use, it is strictly prohibited to pull diagonally askew drag, easy to cause crane overload, the more serious will make the wire rope in the drum around the mess or winding on the drum, pulling off the wire rope, accidents.

3. Causes of electric hoist failure: electric hoist work often has abnormal sounds and is accompanied by different noise

a. The motor starts barely abnormal sound and noise, we have to check whether it is lifting too much overload, the power supply voltage is too low, or the brake is not fully open caused, if it is to reduce the lifting capacity in the rated range of lifting, adjusting the power supply voltage in line with the requirements, adjust the brake clearance, troubleshooting before you can carry out lifting work.

b. When there is a regular strong and weak “humming” sound from the motor immediately stops working, to check whether the power supply or motor single-phase operation; issue a “thump a thump” of “humming “sound to check whether the bearing is damaged; when the whole motor issued by a very high “buzz” sound, immediately stop working, check whether the coupling axis is incorrect or the motor has no slight sweep. Only after the elimination of the fault, you can continue to work.

c. Reducer transmission noise, should stop immediately, the check is caused by the reducer’s lack of oil, poor lubrication or transmission damage, and wear and tear caused by a serious, to add a sufficient amount of oil or re-replace the oil, and repair or replacement of gears, bearings and other transmission parts, otherwise, the reducer will not only send out a greater noise, will also be excessive wear and tear or damage to the gears and bearings, gears due to wear and tear and scrapped.

d. The brake will make a harsh screaming sound, which is the brake wheel and brake ring relative friction or poor contact between the generated. As long as the overhaul of the brake ring, so that the brake wheel and brake ring taper in line with the ear-splitting sound can be eliminated.

4. Causes of electric hoist failure: the sliding distance exceeds the standard when braking

The electric hoist has not been used for a long time, the brake ring is worn out, the spring pressure decreases, the braking force decreases, and when stopping the downward distance exceeds the standard, this situation should be in accordance with the hoist instructions in the “inspection, adjustments and precautions” to re-adjust the brake nut. It is prohibited to adjust, inspect or repair the brake during hoisting operation. Sliding distance exceeds the standard, first dismantle the brake ring, and check the oil on the braking surface, it will make the brake slippery, this time to thoroughly clean the braking surface to restore the friction coefficient of the braking surface; such as if the brake ring is loose or damaged, as long as the replacement of the braking ring can be; if the brake ring is not damaged, but only with the rear cover cone contact is poor, you should find out the location of the contact is poor, unloading and repairing in order to increase the braking contact surface; gourd motor coupling runaway The coupling of the hoist motor is not working or stuck, which makes the braking effect of the hoist unstable, and should be overhauled or replaced with a new coupling in time. If the brake pressure spring becomes fatigued after long-term use and cannot provide a stable braking effect, the relevant components should be repaired or replaced in time.

5. Causes of electric hoist failure: motor overheating

If the motor overheats because the hoist is overloaded, reduce the weight and lift according to the rated lifting capacity. If not overload still overheats, to motor bearings for relevant checks, and the work process strictly implements the relevant provisions of the motor working system. If the brake clearance is too small, the motor will also overheat when the motor is running, then stop the car and adjust the brake clearance to meet the requirements.

If the coupling screws are not tightened, the screws should be tightened in time to eliminate the fault. At the same time, the frequent use of the start, and brake device will also make the motor overheat, so, should minimize the frequent use of the start, and brake devices.

6. Causes of electric hoist failure: work lifting limiters do not limit the position

a. Due to lifting the limiters power supply phase sequence is connected to the wrong, or the wiring is not secure, off due to, should be re-adjusted to the correct power phase sequence, the fall off the power supply wiring is fixed firmly.

b. Due to the stopping of the limit lever loosening, should be adjusted to stop the position of the block and tighten.

7. Causes of electric hoist failure: heavy sliding or running when the brake can not be

First of all, check the brake ring wear, wear serious immediately replace the brake ring, at the same time to see whether the brake gap is too large, too large to adjust the brake gap, so that it meets the requirements of the gap regulations. Secondly, check whether the motor shaft end or gear bearing end fastening screws are loose such as loose to tighten the loose screws.

8. Causes of electric hoist failure: reducer oil seepage or leakage

a. Oil seepage or leakage in the gearbox cover and box between the body, can be determined to be the seal is not installed in place or damage caused by the disassembly of the overhaul or replacement of new seals.

b. Oil seepage or leakage in the reducer linkage, can be determined to be caused by loose screws, to tighten the screws after the shutdown.

c. Too much refueling, the oil to the position of the prescribed refueling can be.

9. Causes of electric hoist failure: button action failure, press not reset

a. Button spring fatigue, damage, timely replacement of the spring.

b. Too much dust and dirt in the button, clean up in time so that the button to keep clean.

c. Circuit breakers or power connectors lost, this time should replace the cable or rewire.

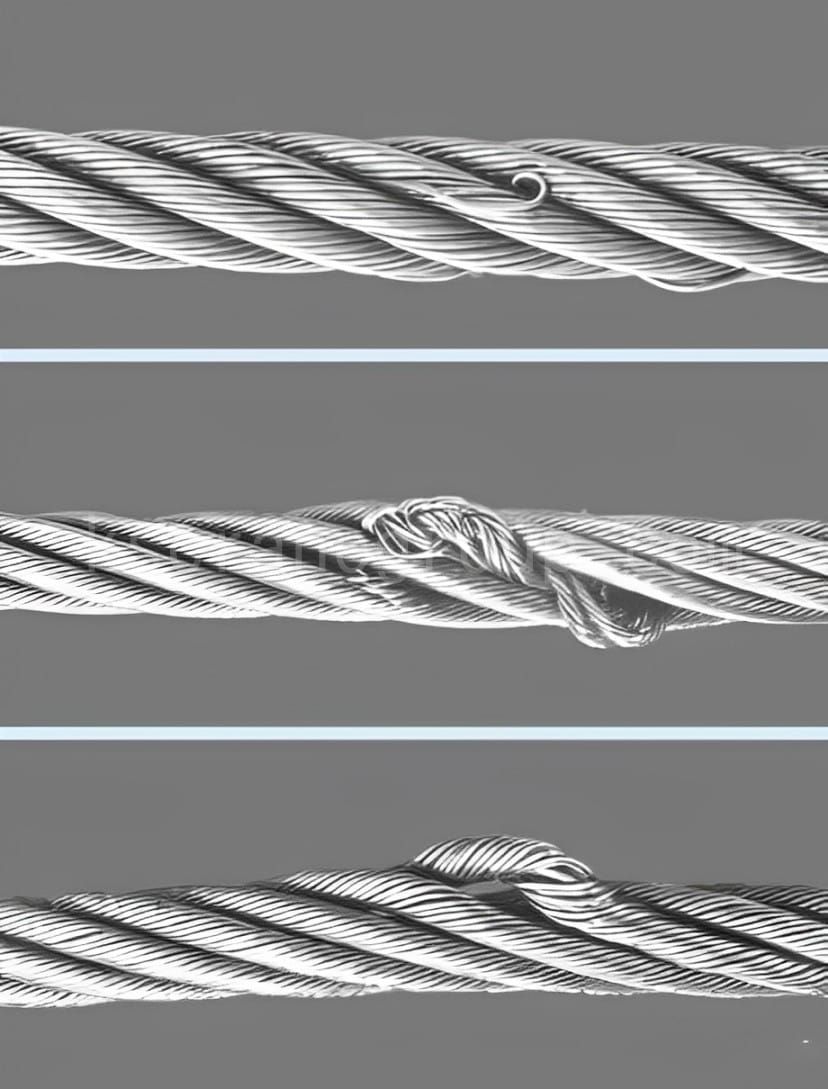

10. Causes of electric hoist failure: wire rope wear, deformation and cut-off

a. Wire rope wear, mainly diagonal hanging so that the wire rope and shell grinding, wire rope diameter is too large. Lifting reasonable selection of wire rope, try not to hang diagonally, in order to avoid wire rope wear.

b. Wire rope deformation, the main reason for deformation is that the rope is deformed because of the mess caused by slant hoisting and there is no rope guide, the wire rope is squeezed and deformed. This requires us to operate in strict accordance with the regulations and should be installed rope guide.

c. The wire rope cut off, mainly lifting limiters fails to be pulled off, lifting too much overload and the wire rope has reached the end-of-life standard, still in use. Lifting in order to avoid accidents due to wire rope cut off, in strict accordance with the regulations lifting, wire rope to reach the end-of-life standard to be replaced in time. Limiter failure is pulled off, to immediately repair or replace the limiter.

Conclusion

The production of electric hoist failure often causes to analyze, judgment, and put forward overhaul measures and practices, greatly improving the ability to deal with accidents and efficiency, so that the number of equipment failures is significantly reduced, the elimination rate of equipment decreases year by year, the equipment to meet the standards of the intact rate increased year by year, reducing the burden of personnel work, saving a lot of manpower and material resources, and improve the economic efficiency of the enterprise.

Why Choose Kuangshan Crane

Kuangshan Crane, as a leading brand in the industry, provides high-performance cranes complying with international standards such as FEM, CMAA, ISO, etc., which are widely used in many industries such as steel, energy, shipbuilding, logistics, manufacturing, etc. Kuangshan Crane is one of the top 10 overhead crane manufacturers in the world, and has won the trust of customers all over the world by its excellent technical strength, rich industrial experience and outstanding product quality. Whether it is a standardised crane or a highly customised industrial solution, Kuangshan Crane offers the optimal choice for your business, boosting productivity and ensuring safe and reliable lifting operations!

Do you like what we do?Share it

TAGS: Electric Hoist,Electric Hoist Failure