- EQUIPMENT

- special cranes

- Industry Crane

- Hoist & Winch Trolley

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

A Comprehensive Guide to Selecting the Right Crane Rail Standard for Your Application

19 Sep, 2023

Cranes are indispensable pieces of equipment in industry and construction, they are used to move and lift heavy loads and therefore require a high level of precision and quality standards in their design and installation. Crane rails are a key component in supporting the travel of cranes, and they must meet a range of standards and specifications to ensure the safety, stability and efficiency of the equipment.

Definition of crane rail

A crane rail is a linear structure used to support and guide a crane’s travel, usually made of high-strength steel with a specific geometry. It allows the crane to move horizontally within the work area for precise load handling and position control.

Crane rail material

Crane rails are usually made of high-strength steel to ensure durability and load capacity. Common steel materials include carbon and alloy steels. These materials need to meet specific chemical composition, mechanical properties and heat treatment standards to ensure their suitability for heavy industrial applications.Crane rail classification

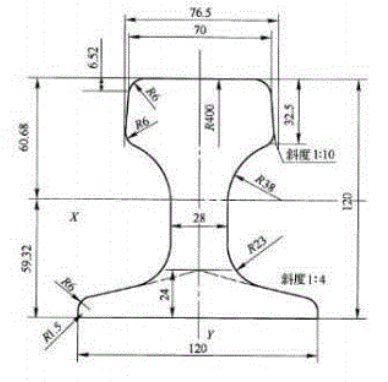

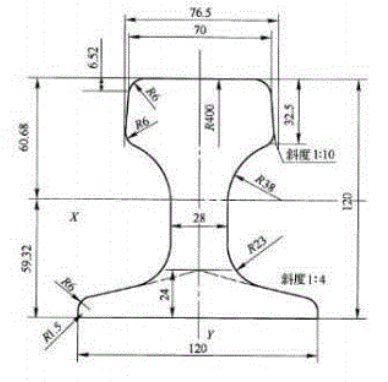

QU70 :

- Parameters: The “QU” in the name of the QU70 rail stands for track and the number “70” indicates the mass of the rail, usually expressed in kilograms per meter (kg/m).

- Dimensions: QU70 rails are larger in size, with a wider base and higher side heights.

- Width of base: usually around 70 mm (2.75 inches).

- Side Height: Usually around 120 mm (4.7 inches).

- Applicable crane types: QU70 rails are suitable for medium-sized cranes, such as bridge cranes and gantry cranes.

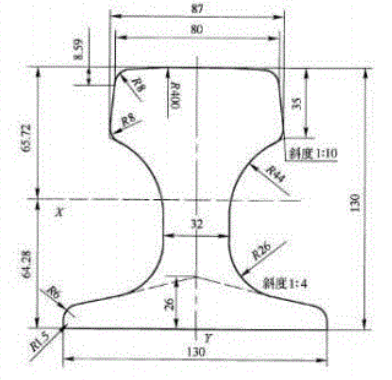

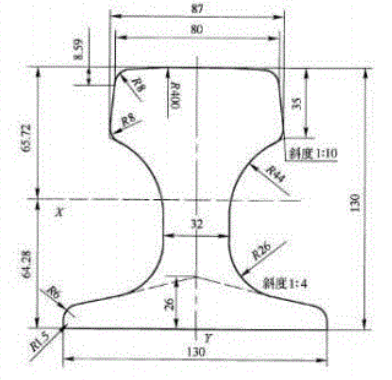

QU80 :

- Parameters: QU80 rails are similar to QU70 rails, but with greater mass.

- Dimensions: QU80 rails have a higher mass and usually also a larger base width and side height.

- Base width: Usually around 80 mm (3.15 inches).

- Side Height: Typically around 130mm (5.1 inches).

- Applicable crane types: QU80 rails are suitable for medium and heavy cranes, such as bridge cranes and large gantry cranes.

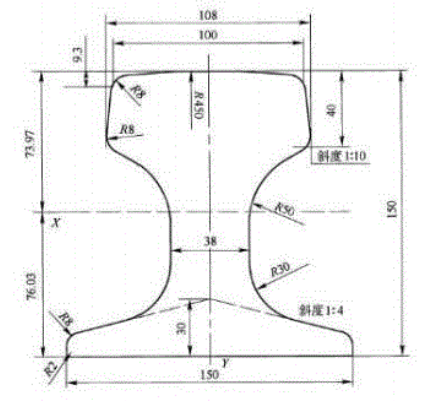

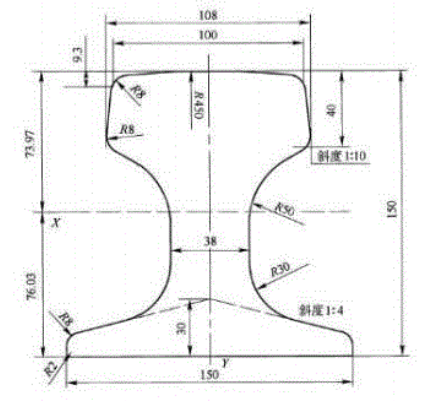

QU100 :

- Parameters: The “QU” in the name of QU100 rails stands for the rail, while the number “100” indicates the mass of the rail, usually expressed in kilograms per meter (kg/m).

- Size: QU100 rails usually have a higher mass and larger dimensions.

- Width at base: usually around 100 mm (3.94 inches).

- Side Height: Usually around 150mm (5.9 inches).

- Applicable crane types: QU100 rails are suitable for large and heavy cranes, such as harbor cranes.

QU120 :

- Parameters: The QU120 rail is an extra heavy duty rail with a very large mass.

- Dimensions: The QU120 rail has a very large base width and side height.

- Base width: usually around 120 mm (4.7 inches).

- Side Height: Usually around 170 mm (6.7 inches).

- Applicable Crane Types: QU120 rails are typically used for large harbor cranes, mining cranes, and other crane applications where extreme loads are required.

Crane rail standard and allowable deviation

The fixed length of steel rail is 9m, 9.5m, 10m, 10.5m, 11m, 11.5m, 12m, 12.5m, and the length of short gauge rail is 6m~8.9m(advanced by 100mm). The quantity of short gauge rail is negotiated between the supply and demand sides and indicated in the contract, but it should not be more than 10% of the total weight of one batch of order. Allowable deviation of rail size should be in accordance with the table.

Allowable deviation of straightness and torsion

The permissible deviation of straightness and torsion of rails should be in accordance with the table.

Delivery weight

Rails are generally delivered according to theoretical weight. After negotiation between supply and demand parties and stated in the contract, it can also be delivered according to the actual weight. The density of steel is calculated according to 7.85g/cm2. Theoretical weight and calculation data of rails are shown in the table.

Purchasing Precautions

Contents of order

The contract or order for ordering according to this standard shall include the following contents:- This standard number;

- Product name;

- Model number;

- Grade number;

- Quantity, length (fixed-foot, non-fixed-foot);

- Special requirements.

Packaging, marking and quality certification

Marking:On the rail waist on one side of each rail, the following clear, raised signs should be rolled out at every 4m interval, with a character height of 20mm~28mm and a raised height of 0.5mm~1.5mm:- Manufacturer’s mark;

- Model number;

- Brand number;

- Manufacturing year (two digits at the end of the rolling year), month.

Do you like what we do?Share it