- SPRZĘT

- dźwigi specjalne

- Przemysł Żurawia

- Wózek wyciągarki i wciągarki

-

Rozrzutnik CRANE

-

Magnesy elektromagnetyczne do podnoszenia dźwigów

-

Elektromagnes podnoszący do obracania i zawieszania bocznego

-

Elektromagnes podnoszący do grubych płyt

-

Specjalistyczny elektromagnes do podnoszenia blach stalowych

-

Elektromagnesy podnoszące do podnoszenia płyt stalowych

-

Elektromagnes podnoszący do szyn ciężkich i stali profilowanej

-

Elektromagnes podnoszący do szybkiego wiertła (pręt zwinięty)

-

Elektromagnes podnoszący do prętów zbrojeniowych i rur stalowych

-

Elektromagnes podnoszący do wiązek prętów zbrojeniowych i stali profilowanej

-

Elektromagnes podnoszący do kęsów, kęsów dźwigarów i płyt

-

Elektromagnes podnoszący do złomu stalowego

-

- Rozpieracz dźwigu

- Kleszcze i zaciski dźwigowe

-

Magnesy elektromagnetyczne do podnoszenia dźwigów

- CZĘŚCI DŹWIGU

- Wózek transferowy

5 suwnic stanowiskowych do usprawnionego transportu materiałów: od wolnostojących do jednoszynowych

Systemy podnoszenia stanowisk roboczych ze stalowych lub aluminiowych profili zmieniły tradycyjne przemysłowe rozumienie dźwigów. Konstrukcja dźwigów stanowiskowych jest lżejsza, łatwiejsza w montażu i bardziej ergonomiczna, co stanowi rewolucyjną poprawę wydajności pracy, która zapewnia bardziej opłacalny wybór.

Rodzaje suwnic stanowiskowych

Powi\u0119ksz obrazek: Single girder suspended workstation bridge cranes","alt":"Single girder suspended workstation bridge cranes"}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

Single girder suspended workstation bridge cranes

Powi\u0119ksz obrazek: Extending cranes","alt":"Extending cranes"}" data-wp-interactive="core/image" class="wp-block-image size-full wp-lightbox-container">

Extending cranes

Suwnice mostowe wolnostojące

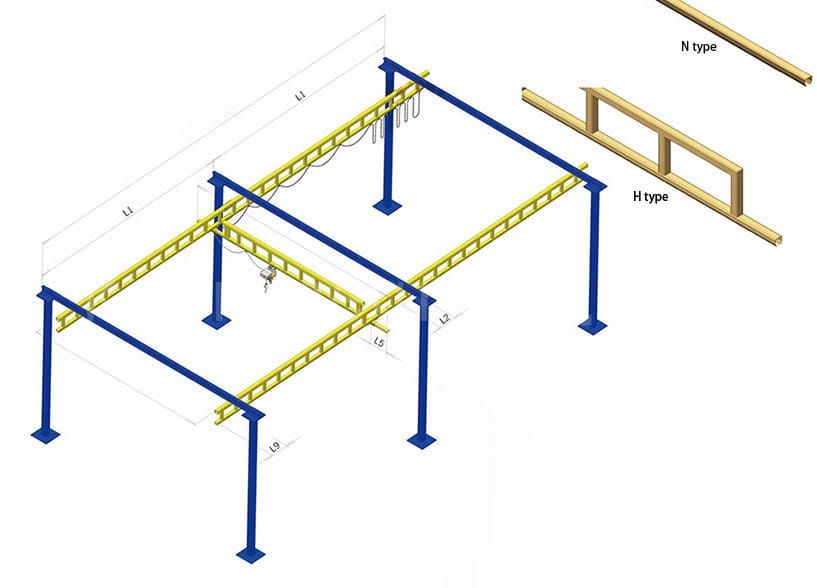

Wolnostojące suwnice stanowiskowe z szyną typu C, która jest zaprojektowana z zamkniętą szyną o wysokiej wytrzymałości i lekkości, mogą skutecznie zmniejszyć zużycie wózka szynowego i wózka podnośnika. W przypadku niewystarczającej liczby punktów podnoszenia można użyć stalowej szyny kratownicowej, aby wzmocnić łożysko szyny, tak aby uzyskać większą rozpiętość.

Zalety wolnostojących suwnic pomostowych

- Szyna zamknięta, brak spawania w przekroju, doskonała wydajność, prostoliniowość ±1 mm na 6 m;

- Konstrukcja otworu o kącie 2° na dolnej krawędzi, automatyczne centrowanie wózka, płynniejsza praca;

- Szyny są walcowane przy użyciu specjalistycznego, zaawansowanego technologicznie systemu walcowania szyn, z pełną kontrolą jakości procesu.

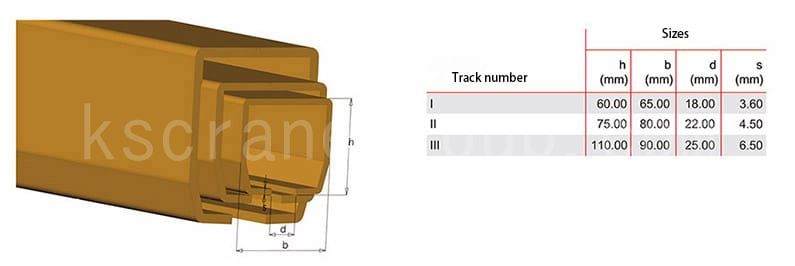

Specyfikacja wolnostojących suwnic pomostowych

Nasze trzy rozmiary torów nadają się do szerokiego zakresu obciążeń do 2000 kg. Pochylona konstrukcja toru zapewnia, że wózki poruszają się po linii prostej w obrębie toru i zmniejsza gromadzenie się kurzu w obrębie toru. Dzięki temu wózek może poruszać się płynnie w obrębie toru i wydłuża się żywotność toru, który wymaga jedynie 1-4% udźwigu do obsługi lekkiego dźwigu.

| Rzadki ładunek (kg) | Numer utworu | Rozpiętość belki głównej (mm) | L1 maks. (mm) | L2 maks. (mm) | L5 maks. (mm) | L9 maks. (mm) |

|---|---|---|---|---|---|---|

| 250 | W | 2500 | 1900 | 1200 | 600 | 1200 |

| Ja | 10000 | 9000 | 1200 | 600 | 1200 | |

| 500 | II-N | 2500 | 1800 | 1200 | 600 | 1200 |

| II-H | 10000 | 9000 | 1200 | 600 | 1200 | |

| 1000 | III-N | 3000 | 2000 | 1200 | 600 | 1200 |

| III-H | 10000 | 9000 | 1200 | 600 | 1200 | |

| 2000 | III-H | 9000 | 8000 | 1200 | 600 | 1200 |

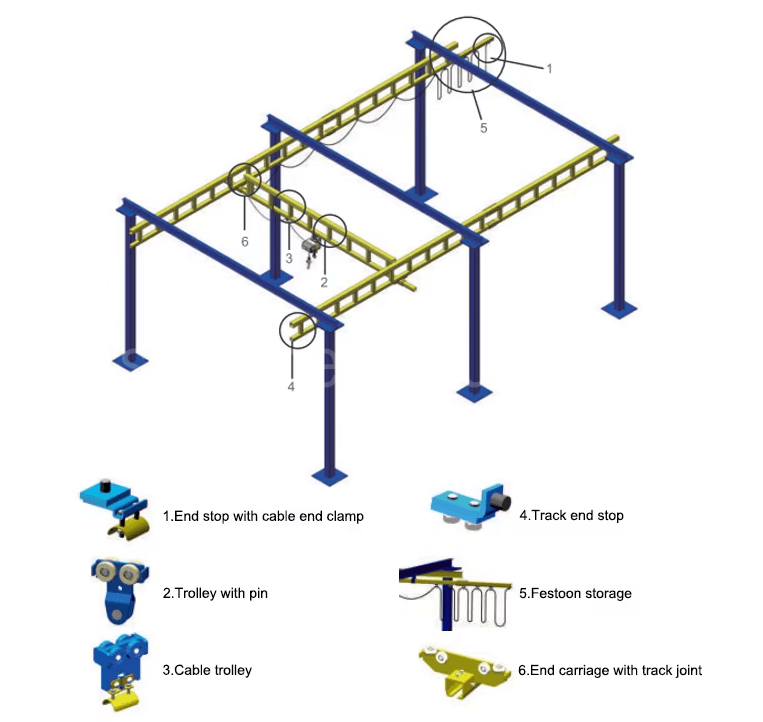

Szczegóły wolnostojących suwnic pomostowych

Suwnice pomostowe wolnostojące Formy montażu

Rozwiąż ograniczenia przestrzenne, transport materiałów poza zasięgiem konwencjonalnym

Rozwiąż problem niezgodności wielkości stanowiska roboczego do podnoszenia materiałów za pomocą suwnicy przesuwnej

Rozwiąż istniejące ograniczenia przestrzenne i brak miejsca do podnoszenia

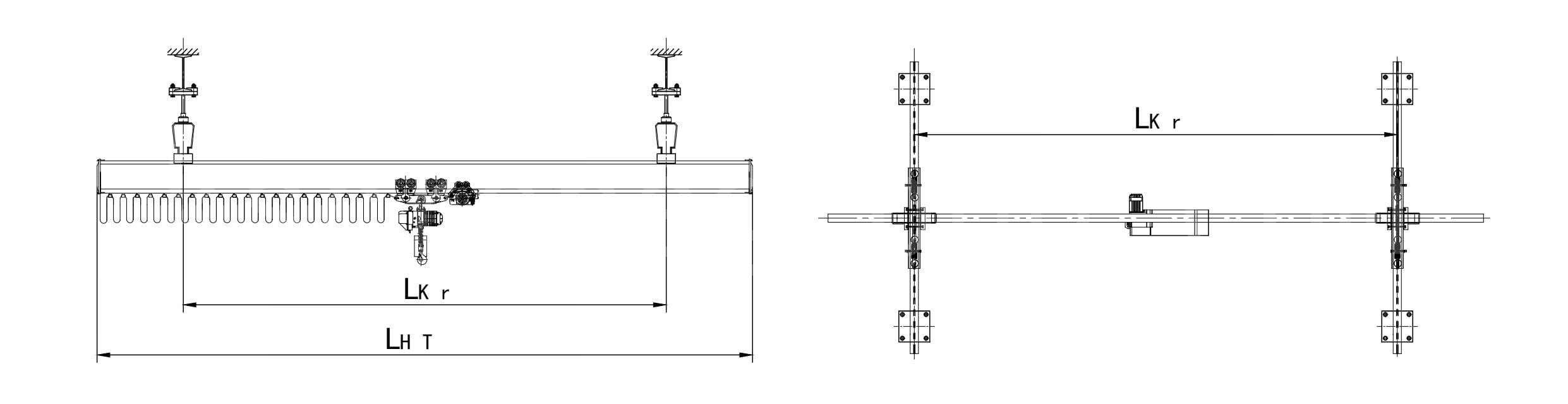

Suwnice mostowe podwieszane dwudźwigarowe

Podwieszane dwudźwigarowe suwnice stanowiskowe mają duży udźwig i są szeroko stosowane do podnoszenia ciężkich ładunków. Szeroki zakres towarów może być łatwo transportowany. Może wykonywać prace związane z przenoszeniem ładunków na powierzchni i nad głową, zapewniając jednocześnie szybkie, niezawodne i precyzyjne pozycjonowanie, nawet przy ciężkich ładunkach i dużych rozpiętościach. Wciągnik jest umieszczony między dwoma głównymi sekcjami belki, aby zapewnić maksymalne wykorzystanie przestrzeni do podnoszenia.

Zalety systemów suwnic stanowiskowych podwieszanych dwudźwigarowych

- Transport ładunków na dużych wysokościach

- Małe odległości między elementami w celu maksymalnego wykorzystania przestrzeni

- Prosta, bezpieczna i niezawodna obsługa

- Doskonałe wymiary montażowe

- Ekonomiczne rozwiązania można dostosować do wymagań warsztatu klienta – nawet w ograniczonych przestrzeniach

- Szeroki zakres zastosowań dzięki modułowej konstrukcji systemu

- Może być również używany jako dźwig manipulacyjny – doskonała konstrukcja dla zaawansowanych systemów obsługi.

- Nośność znamionowa do 3200 kg

- Wciągnik montowany jest pomiędzy głównymi dźwigarami suwnicy, aby zmaksymalizować skok haka

- Maksymalne rozpiętości można uzyskać stosując wiele wieszaków (suwnice poruszające się na więcej niż dwóch torach), aby pokryć duże obszary magazynowe i produkcyjne

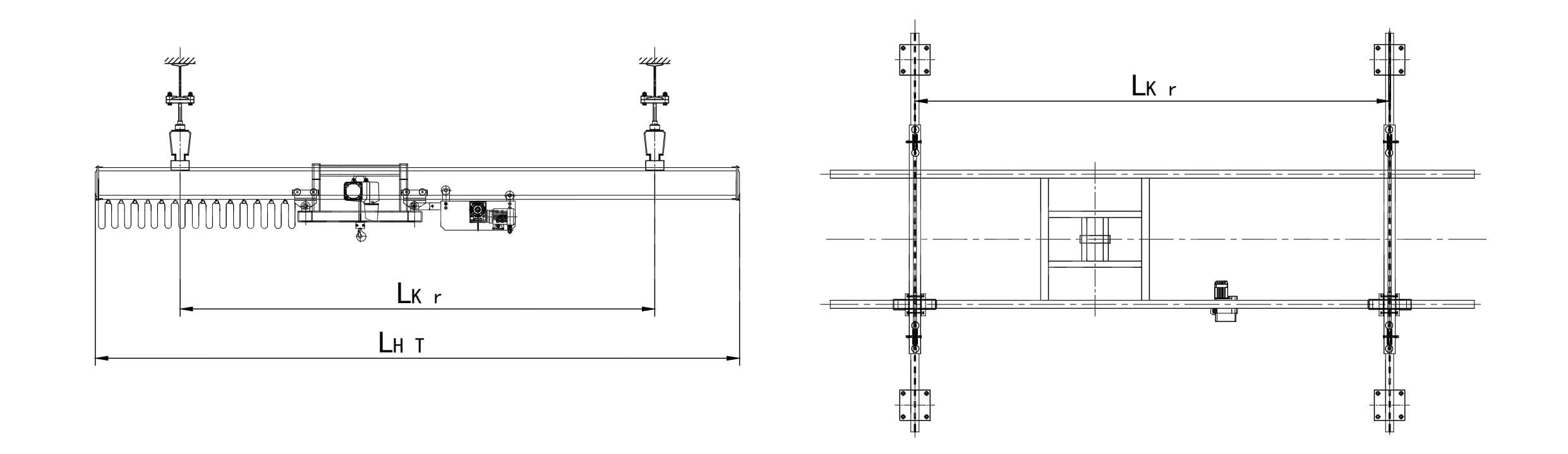

Parametry systemów suwnic stanowiskowych podwieszanych dwudźwigarowych

| Numer utworu | Masa własna (kg) | |||||||

| 125 | 250 | 500 | 1000 | 1600 | 2000 | 3000 | ||

| II | LKr(minimalny) | 10.0 | 10.0 | 8.5 | 6.2 | 4.6 | 3.65 | |

| LHT | 12.0 | 12.0 | 11.5 | 7.0 | 5.0 | 4.0 | ||

| II-T (standardowy) | LKr(minimalny) | 10.5 | 10.5 | 10.5 | 9.1 | 7.4 | 6.7 | Proszę zapytać |

| LHT | 14.0 | 14.0 | 14.0 | 12.0 | 9.0 | 7.0 | Proszę zapytać | |

Minimalna długość wspornika 125 mm

Można dostosować do wymagań klienta

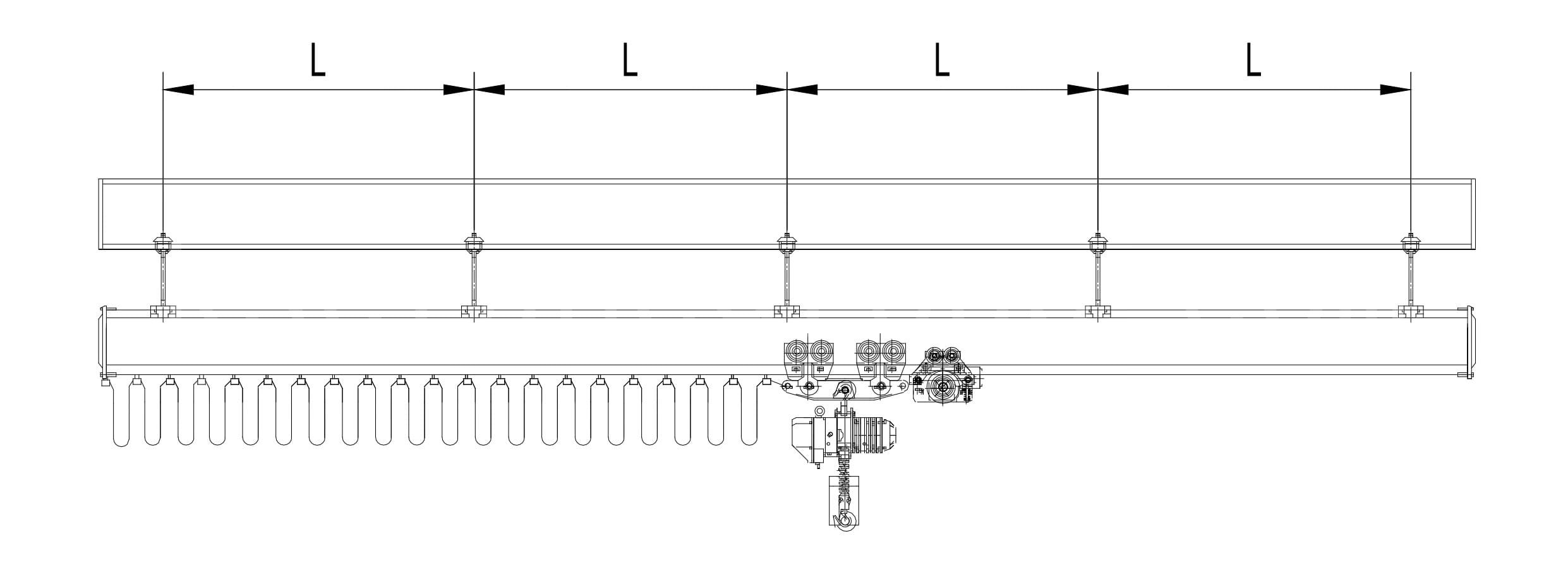

Suwnice mostowe jednodźwigarowe podwieszane

Stanowisko robocze podwieszone na pojedynczym dźwigarze dźwigi mostowe są dobrze zaprojektowane i bardzo niezawodne do transportu na dużych wysokościach. Systemy suwnic stanowiskowych z pojedynczym dźwigarem mają duży promień roboczy, mogą zmniejszyć zjawisko wstrząsania ładunkiem, są szybkie i niezawodne w określonym obszarze do transportu nad głową i dokładnego pozycjonowania różnych towarów, o wysokiej wydajności, oszczędności energii, małej całkowitej powierzchni, łatwe w użyciu i konserwacji oraz innych cechach.

Zalety systemów suwnic stanowiskowych podwieszanych jednodźwigarowych

- Można go łatwo przenosić ręcznie, jest lekki

- Przegubowe połączenie głównej belki dźwigu z wózkiem zapewniające płynną i bezproblemową pracę

- Ekonomiczne rozwiązania dostosowane do wymagań warsztatu klienta – nawet w ograniczonych przestrzeniach

- Szeroki zakres zastosowań dzięki modułowej konstrukcji systemu

- Dźwig może być również obsługiwany na torach nierównoległych

- Maksymalne wykorzystanie przestrzeni

- Transport ładunków na dużych wysokościach

- Idealne wykorzystanie przestrzeni dzięki niewielkim odległościom między urządzeniami

Parametry systemów suwnic stanowiskowych podwieszanych jednodźwigarowych

| Numer utworu | Masa własna (kg) | |||||||

| 80 | 125 | 250 | 500 | 1000 | 1600 | 2000 | ||

| II | LKr(minimalny) | 7.75 | 7.75 | 7.45 | 6.0 | 3.5 | ||

| LHT | 8.0 | 8.0 | 8.0 | 7.0 | 4.0 | |||

| II-T (standardowy) | LKr(minimalny) | 10.5 | 10.5 | 9.3 | 6.5 | |||

| LHT | 14.0 | 13.0 | 11.0 | 7.0 | ||||

Minimalna długość wspornika 125 mm

Można dostosować do wymagań klienta

Suwnice jednoszynowe

Suwnice jednoszynowe oferują rozwiązania dostosowane do Twoich konkretnych potrzeb w zakresie liniowych prac związanych z przenoszeniem na wysokości. Unikalne zalety można uzyskać, montując różne opcje. Suwnica jednoszynowa nadaje się do wszystkich naszych urządzeń podnoszących i oferuje uniwersalne rozwiązanie do podnoszenia i przenoszenia ciężarów. Standardowe połączenia i elementy mocujące zapewniają łatwy montaż. Modułowa konstrukcja umożliwia wprowadzanie zmian w przypadku zmiany warunków produkcji, w prosty i szybki sposób.

Zalety suwnic jednoszynowych

- Proste, ręcznie obsługiwane proste odcinki – dostępne profile aluminiowe

- Udźwig do 3200 kg

- Wysoki stopień elastyczności w dostosowywaniu linii poprzez łączenie prostych i zakrzywionych szyn, rozjazdów i obrotnic

- Możliwość bezpośredniego połączenia punktów chwytania i umieszczania w układzie odwrotnym lub obwodach zamkniętych

- Praca półautomatyczna lub w pełni automatyczna w połączeniu z pracą ręczną

- Sprzęt kompozytowy, który umożliwia precyzyjne dopasowanie trasy do różnorodnych wymagań konstrukcyjnych różnych warsztatów poprzez łączenie zastosowania różnych komponentów

- Można go również przenieść na sąsiedni dźwig podwieszony za pomocą urządzenia blokującego

- Może być używany jako nośnik sprzętu (np. sprzętu testowego, elektronarzędzi i narzędzi wiatrowych)

- Kompleksowy system komponentów KBK obejmuje niezawodne środki transportu pośredniego (wózki kablowe, opaski zaciskowe itp.) do transportu układów cieczowych, układów sprężonego powietrza i układów zasilania dźwigów i innego sprzętu mobilnego.

- Systemy szynowe dwuszynowe jako nośniki sztywnego sprzętu do transportu bliskiego, takiego jak manipulatory, urządzenia podnoszące itp.

Parametry suwnic jednoszynowych

| Numer utworu | Masa własna (kg) | ||||||

| 125 | 250 | 500 | 1000 | 1600 | 2000 | ||

| II | Dł. szer. (maks.) | 6.0 | 4.0 | 2.5 | 2.4 | 1.2 | |

| II-T (standardowy) | Dł. szer. (maks.) | Proszę zapytać | Proszę zapytać | Proszę zapytać | Proszę zapytać | Proszę zapytać | |

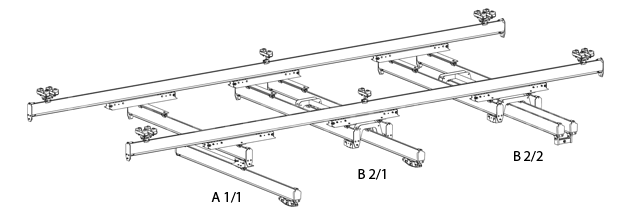

Rozsuwane dźwigi

Przedłużane belki główne mogą być stosowane głębiej, jeśli efektywny obszar pokrycia systemów podnoszenia stanowisk roboczych jest wymagany poza granicami ich konstrukcji nośnej. Przedłużane i teleskopowe suwnice dźwigarowe umożliwiają przenoszenie ładunku poza tor suwnicy. To rozwiązanie umożliwia bardziej efektywne wykorzystanie przestrzeni i pozwala na wykorzystanie dostępnej przestrzeni z idealną wydajnością. Nasze rozwiązania spełniają określone potrzeby. Przedłużane suwnice są często stosowane w kontenerach lub ciężarówkach, a w niektórych przypadkach na szynach narzędziowych w przemyśle motoryzacyjnym.

Rozszerzanie zalet dźwigów

- Suwnice przedłużające, mocowane do dźwigara głównego, mogą wystawać poza szerokość toru suwnicy.

- Suwnice rozsuwane składają się z części stałej i części dźwigu, którą można rozsuwać w obu kierunkach.

- Główna belka suwnicy może wystawać nawet 2500 mm poza rozpiętość szyny.

- W zależności od projektu, dźwigar główny może wystawać poza szerokość toru podsuwnicowego w jednym lub obu kierunkach.

- Można go używać do precyzyjnego podnoszenia i umieszczania ładunków w miejscach trudno dostępnych (np. między kolumnami).

- Efektywne wykorzystanie powierzchni warsztatu (np. jeśli warsztat zostanie później rozbudowany, nowy obszar można pokryć bez dodatkowych szyn dźwigowych)

- Możliwość pracy pod rurami wydechowymi, kanałami grzewczymi i kablami

Schemat ilustrujący rozsuwanie dźwigów

Skontaktuj się z nami

- Bezpłatna i szybka wycena produktu.

- Dostarcz Państwu nasz katalog produktów.

- Twoje lokalne projekty dźwigów z naszej firmy.

- Zostań naszym agentem i zarabiaj prowizję.

- Wszelkie pytania, skontaktuj się z nami.