- PERALATAN

- kren khas

- Kren Industri

- Troli Angkat & Win

-

Penyebar KREN

-

Magnet Pengangkat Elektromagnet Kren

-

Mengangkat Elektromagnet untuk Memusing dan Digantung Sisi

-

Mengangkat Elektromagnet untuk Plat Tebal

-

Elektromagnet Khusus untuk Mengangkat Plat Keluli

-

Mengangkat Elektromagnet untuk Mengangkat Plat Keluli

-

Mengangkat Elektromagnet untuk Rel Berat dan Keluli Berprofil

-

Mengangkat Elektromagnet untuk Wier Berkelajuan Tinggi (Bar Bergelung)

-

Mengangkat Elektromagnet untuk Rebar dan Paip Keluli

-

Mengangkat Elektromagnet untuk Rebar Terikat dan Keluli Berprofil

-

Mengangkat Elektromagnet untuk Billet, Girder Billet dan Slab

-

Mengangkat Elektromagnet untuk Sisa Keluli

-

- Penyebar Kren

- Kren Mengangkat Tong dan Pengapit

-

Magnet Pengangkat Elektromagnet Kren

- BAHAGIAN KREN

- Troli Pemindahan

5 Reka Bentuk Kren Kilang Kertas untuk Susun Atur Bengkel Industri Kertas yang Mudah

Tarikh: 19 Feb, 2025

Jadual Kandungan

Mengikut pengalaman bertahun-tahun dalam penyelenggaraan dan transformasi pembuatan kren, melalui analisis dan perbandingan pelbagai susun atur dan jenis kren di bengkel kilang kertas, mengemukakan pemilihan yang munasabah dan skema susun atur yang optimum. Penyediaan atau transformasi teknikal projek baru dan lama dalam kilang kertas, reka bentuk kren kilang kertas atau penyelenggaraan dan transformasi mempunyai nilai rujukan yang tinggi.

Kepentingan pemilihan kren yang munasabah dan susun atur yang optimum

Di bengkel kilang kertas, kren adalah pautan yang sangat diperlukan dalam proses pembuatan kertas, terutamanya digunakan untuk mengangkat dan memasang peralatan mesin kertas, kerjanya agak sibuk. Disebabkan oleh proses khas pembuatan kertas, persekitaran bengkel kertas adalah keras (suhu tinggi, kelembapan tinggi, udara dengan habuk kertas) dan tahap penggunaan kren dan kekerapan penggunaan dan sebagainya, jadi kren kilang kertas dan kren jambatan am mempunyai ciri-ciri yang jelas. Oleh itu, pemilihan dan susun atur kren yang munasabah bukan sahaja dapat mengurangkan pelaburan awal kren dan kos pembinaan loji tetapi juga mengurangkan kos operasi kren dan kos penyelenggaraan, mengurangkan kehilangan masa henti mesin kertas, meningkatkan kecekapan korporat dan meningkatkan kelebihan daya saing perusahaan.

Bentuk dan susun atur kren kilang kertas yang lalu

Sebelum ini, kebanyakan bengkel kertas kilang kertas reka bentuk susun atur 3 kren, kren menggunakan struktur jambatan galang dua elektrik, mekanisme mengangkat menggunakan bentuk win. Antaranya, bahagian basah mesin kertas mempunyai kren jambatan galang berkembar 3-troli (selepas ini dirujuk sebagai jambatan galang berganda), terutamanya digunakan untuk penyelenggaraan mesin kertas (dirujuk sebagai 'kren perkhidmatan'); kader mesin kertas mempunyai dua set jambatan galang berkembar troli berkembar yang sama, terutamanya digunakan untuk mengangkat gulungan kertas (dirujuk sebagai 'kren gulung kertas'), 1 untuk kerja harian, 1 lagi untuk sandaran, untuk mengelakkan kegagalan kren yang disebabkan oleh masa henti mesin kertas, lihat Rajah 1. 3 kren tidak digunakan sepenuhnya, yang pada asasnya tidak digunakan untuk jangka masa yang lama, yang pada asasnya tidak digunakan untuk jangka masa yang panjang hanya meningkatkan kos pelaburan, tetapi juga meningkatkan kos pengurusan peralatan, penyelenggaraan, alat ganti dan sebagainya.

Kerana kebanyakan keperluan tahap kerja kren kilang kertas adalah lebih tinggi, keseluruhan mesin A6, agensi M6, manakala tahap kerja angkat elektrik biasa sebelumnya adalah rendah (kebanyakan

Bentuk dan susun atur kren kilang kertas moden

Melalui analisis teknikal terperinci, reka bentuk rasional dan pemilihan komponen berkualiti tinggi, anda boleh menggunakan 2 (atau sekecil 1) jambatan galang dua angkat elektrik dan bukannya 3 jambatan universal elektrik sebelumnya. Dengan cara ini, bilangan kren boleh dikurangkan sebanyak 1/3, tetapi juga disebabkan oleh pengurangan tekanan roda kren, pengurangan ketinggian, sepadan dengan mengurangkan keratan rentas rasuk trek, keratan rentas lajur, spesifikasi trek, mengurangkan ketinggian pembinaan loji, menjimatkan jumlah pelaburan kira-kira 35%. Penjimatan tenaga dan penjimatan kuasa kerana pengurangan kuasa kren. Reka bentuk dan susun atur sedemikian, digunakan dalam banyak barisan kertas, 7 tahun pengalaman terkumpul, dengan faedah ekonomi yang jelas. Analisis berikut membandingkan kelebihan dan kekurangan pelbagai susun atur dan jenis kren.

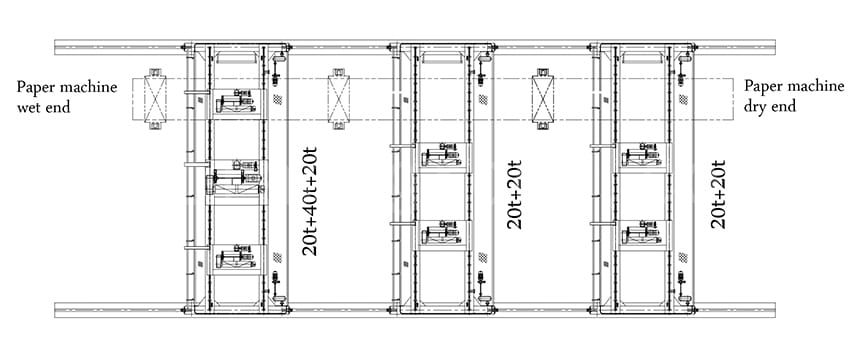

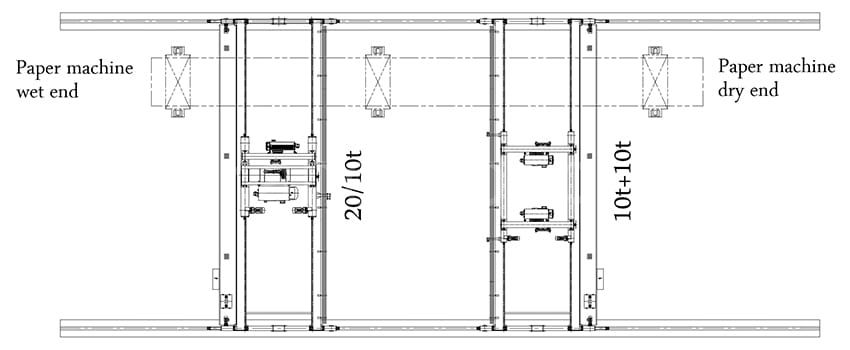

Program kren kilang kertas 1

Setiap bengkel kertas menyediakan 2 set jambatan yang sama, 1 ialah mesin kertas hujung kering kren roll kertas, 1 ialah mesin kertas hujung basah kren perkhidmatan (mengikut keadaan sebenar mesin kertas dan sebagainya, malah hanya boleh menyediakan kren). Terdapat 3 troli di atas jambatan kren. 2 troli luar digunakan untuk mengangkat gulungan kertas, gulungan kertas kosong dan tujuan lain; troli tengah digunakan untuk penggantian pelbagai gulungan dan silinder mesin kertas dan perkhidmatan penyelenggaraan lain, dan juga boleh digunakan sebagai troli sandaran untuk mengangkat gulungan kertas sekiranya berlaku kegagalan mana-mana troli luar. Untuk tujuan ini, kelajuan mengangkat 3 troli adalah sama dengan kelajuan larian troli.

Secara amnya mekanisme mengangkat 2 troli luar mempunyai kelas pekerja sekurang-kurangnya M6 (FEM 3m) dan troli tengah digunakan terutamanya untuk perkhidmatan penyelenggaraan, berbanding dengan troli luar. Ia boleh mempunyai tahap kerja yang lebih rendah, contohnya M4 (FEM 1 Am), tetapi dengan kapasiti angkat yang lebih tinggi, biasanya dua kali lebih tinggi daripada yang luar. Contohnya: 20 t/M6 + 40 t/M4 + 20 t/M6. Dengan cara ini, troli tengah mampu mengangkat silinder sahaja, dengan parameter berikut.

| Kategori | Troli I | Troli II | Troli III |

|---|---|---|---|

| Tahap kerja mekanisme mengangkat | M6 | M4 | M6 |

| kapasiti mengangkat/t | 10~60 | 20~120 | 10~60 |

| Kelajuan mengangkat/(m/min) | 4~8 | 3.2~8 | 4~8 |

| Tahap kerja operasi troli | M5~M6 | M4~M5 | M5~M6 |

| Tahap kerja operasi kren | M5~M6 | ||

Faedah terbesar bentuk pembinaan kren ini adalah serba boleh dan kebolehpercayaan. Kren roll kertas juga boleh digunakan untuk perkhidmatan atau sebagai sandaran untuk kren servis. Kebolehpercayaan yang tinggi adalah disebabkan oleh fakta bahawa kegagalan mana-mana troli tidak akan menjejaskan proses pengeluaran.

Jika susun atur bengkel 2 kren sedemikian, kebolehpercayaan adalah sangat tinggi, kehilangan masa henti hampir 0. Jika hanya susun atur 1 kren, kelebihannya adalah pelaburan minimum, tetapi juga untuk memenuhi keperluan pengeluaran harian untuk digunakan, kelemahannya ialah kegagalan mekanisme operasi troli besar akan menjejaskan pengeluaran, harus mengukuhkan kerja penyelenggaraan rutin kren.

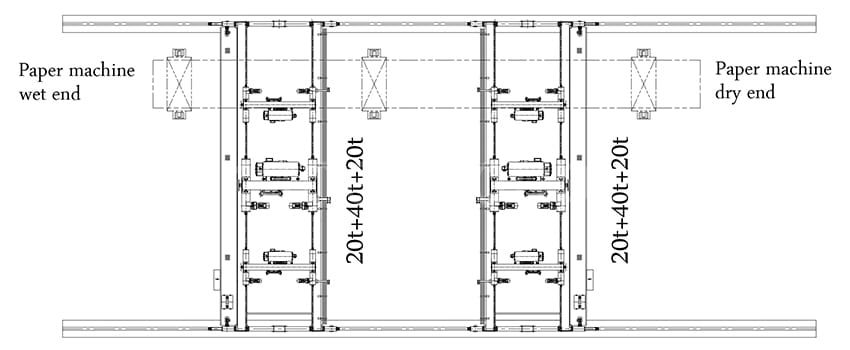

Program kren kilang kertas 2

Merupakan varian program 1, jambatan kren hanya 2 troli, yang mana 1 troli hanya 1 mekanisme angkat, troli lain mempunyai 2 mekanisme angkat, bentuk cangkuk utama. Mekanisme angkat dengan kapasiti angkat yang besar disusun di tengah, cth 20 t+40/20 t. Begitu juga, kelas pekerja 20 t ialah M6 dan kelas pekerja 40 t ialah M4. Persamaan lain terdapat dalam skema 1.

Kelebihan program pembinaan ini ialah trolinya padat, memudahkan kawalan kawalan elektronik, menjimatkan struktur keluli dan bahan kawalan elektronik, mengurangkan kos pembuatan kren. Kelemahan utama ialah kelajuan lintasan tidak disegerakkan disebabkan oleh beban yang berbeza dari 2 mekanisme larian troli, dan langkah-langkah tertentu perlu diambil.

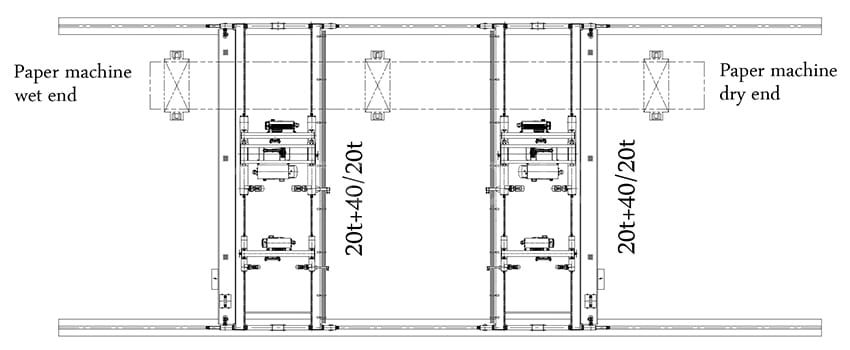

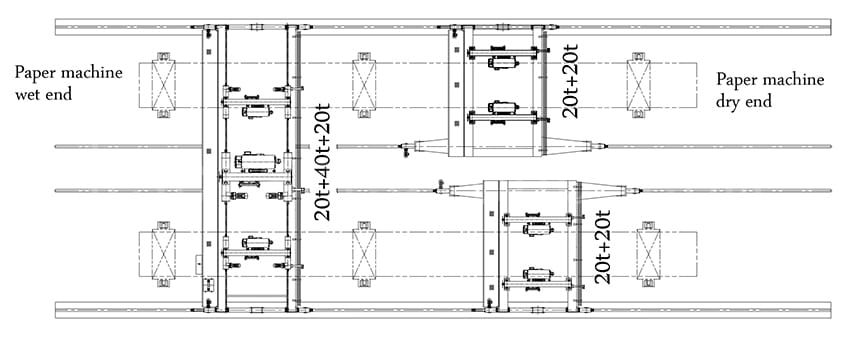

Program kren kilang kertas 3

Setiap bengkel kertas menyediakan 2 jambatan yang berbeza, mesin kertas hujung basah susunan kren perkhidmatan 3-troli, mesin kertas hujung kering susunan kren roll kertas dua-troli. Kerja kren roll kertas agak sibuk, roll kertas + berat rasuk mengangkat hampir dengan kapasiti mengangkat undian kren, tahap kerjanya sekurang-kurangnya M6, seperti: 20 t/M6 + 20 t/M6. Kren servis boleh sama dengan reka bentuk program 1, seperti: 20 t/M6 +40 t/M4 +20 t/M6, bahagian luar 2 troli sebagai sandaran untuk kren gulung kertas, kelajuan mengangkat cangkuk 40t boleh direka dengan kelajuan yang sama seperti cangkuk 20t atau kelajuan yang sama dengan cangkuk 20t. Kelajuan mengangkat cangkuk 40t boleh direka bentuk untuk sama atau berbeza daripada cangkuk 20t. Jika kelajuan berbeza, cangkuk 40t tidak boleh digunakan untuk menggantikan cangkuk 20t untuk mengangkat gulungan kertas.

Oleh kerana kren perkhidmatan hujung basah biasanya digunakan kurang, untuk menjimatkan lagi kos pembuatan kren, mengikut keadaan kerja sebenar, seluruh mesin kren perkhidmatan dan tahap kerja troli luar boleh direka bentuk untuk menjadi satu tahap lebih rendah daripada kren kader, contohnya M5 (FEM 2m).

Kren gulung kertas susun atur dengan troli berganda ini lebih menjimatkan berbanding Pilihan 1, dan kegagalan troli persisian tidak menjejaskan pengeluaran pada dasarnya. Sama seperti program 1, kelemahan adalah bahawa bahagian basah kren biasanya penggunaan rendah, jika mesin kertas diletakkan untuk masa yang lama di atas hujung basah kren, suhu tinggi, kelembapan dan serpihan kertas, dan lain-lain pada struktur keluli kren dan kakisan sistem kawalan elektrik adalah lebih besar, harus cuba meletak kren jauh dari tempat yang lembap.

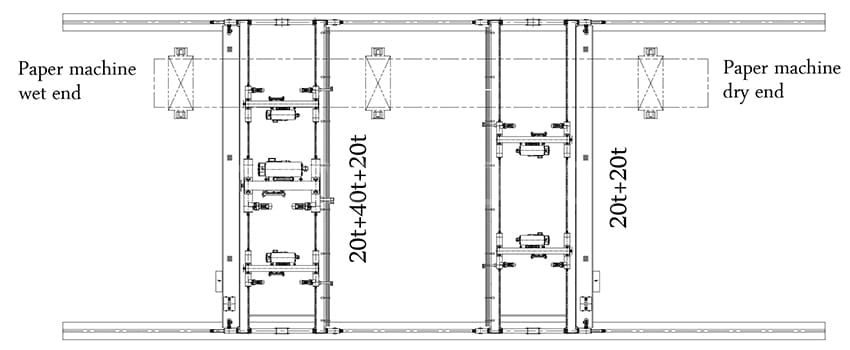

Program kren kilang kertas 4

Setiap bengkel kertas menyediakan 2 mesin jambatan yang berbeza, susunan hujung basah mesin kertas bagi kren servis, susunan hujung kering mesin kertas bagi kren troli tunggal.

Kren roll kertas ialah 2 cangkuk dari dua titik angkat troli yang sama dengan parameter berikut. Struktur ini sesuai untuk kapasiti angkat kecil dan lebar sempit mesin kertas. Kelebihan terbesar kren jenis ini ialah 2 cangkuk disegerakkan secara mekanikal, tetapi jarak antara 2 cangkuk berbeza sedikit dengan ketinggian angkat. Kelebihannya ialah mengurangkan bilangan troli, penjimatan kos yang besar. Kelemahannya ialah apabila mekanisme larian troli gagal, ia akan menjejaskan pengeluaran, dan harus mengukuhkan penyelenggaraan harian kren.

| Kategori | 2.5t+2.5t | 5t+5t | 10t+10t |

|---|---|---|---|

| Tahap kerja mekanisme mengangkat | M6 | M6 | M6 |

| kapasiti mengangkat/t | 5 | 10 | 20 |

| Kelajuan mengangkat/(m/min) | 1/6.3 | 1/6.3 | 0.66/4 |

| Tahap kerja operasi troli | M5~M6 | M5~M6 | M5~M6 |

| Tahap kerja operasi kren | M5~M6 | M5~M6 | M5~M6 |

Program kren kilang kertas 5

Di atas mesin kertas untuk menyediakan jambatan 3-troli untuk penyelenggaraan mesin kertas atau sandaran mengangkat gulungan kertas, mesin kertas kering hujung susun atur tanah 1 hingga 2 separuh kaki mesin angkat elektrik (mengikut barisan pengeluaran mesin kertas untuk menentukan bilangan unit), mesin pintu 2 cangkuk boleh direka bentuk untuk dipasang pada jambatan. Kelebihan susun atur ini ialah mesin pintu didedikasikan untuk mengangkat gulungan kertas, penjajaran sisi adalah tepat, kecekapan tinggi, kebanyakannya digunakan dalam susun atur bengkel yang sama mempunyai 2 atau lebih baris mesin kertas majlis. Kelemahan adalah bahawa jumlah pelaburan dalam peralatan, infrastruktur dan lain-lain besar, ekonomi miskin, aplikasi semasa adalah kurang dan kurang. Skim 1, 2, 3, jika penggunaan mekanisme pengangkat jenis wink troli, disebabkan oleh titik angkat had kiri dan kanan dari garis tengah trek troli adalah lebih jauh, secara amnya perlu mengkonfigurasi 1 ~ 2 3.2 ~ 10t angkat elektrik, tergantung di lantai rasuk utama atau sisi rasuk utama trek garis besar. Jika troli jenis angkat, kerana had titik angkat kecil, kadangkala boleh dikecualikan daripada angkat kecil, yang boleh mengurangkan kos kren.

Pada masa ini, sebahagian daripada tahap kerja reka bentuk angkat elektrik Eropah boleh mencapai M6. troli angkat elektrik ringan, struktur padat, titik angkat tinggi, kedua-dua belah kedudukan had adalah kecil, telah digunakan secara meluas dalam pelbagai kesempatan dan pelbagai industri. Sebilangan besar amalan telah membuktikan bahawa, berbanding dengan troli jenis win, troli angkat bukan sahaja mempunyai kelebihan harga, tetapi juga penunjuk teknikal dan prestasi, hayat, kebolehpercayaan dan aspek lain, boleh menggantikan troli jenis winch jenis QD domestik sepenuhnya.

Kesimpulan

Dari tahun reka bentuk dan pengalaman pembuatan, dari sudut pandangan ekonomi, kepraktisan dan kekerapan penggunaan, susunan program keutamaan ialah 3, 2, 1, 5, 4. Seluruh mesin menggunakan bentuk kren girder berganda dengan angkat elektrik, dengan keutamaan kepada angkat elektrik Eropah sebagai mekanisme angkat, dan mekanisme larian troli besar dan kecil menggunakan struktur pemacu tiga dalam satu. Pemilihan yang munasabah dan pengoptimuman susun atur kren kilang kertas, bukan sahaja dapat mengurangkan kos pelaburan, mengurangkan kos penyelenggaraan dan kos operasi kren, tetapi juga meningkatkan kecekapan, mengurangkan kerugian masa henti, dan membawa faedah ekonomi yang lumayan untuk perusahaan kertas.

Adakah anda suka dengan apa yang kami lakukan?Kongsikan

TAGS: Reka Bentuk Kren Kilang Kertas