- EQUIPMENT

- special cranes

- Industry Crane

- Hoist & Winch Trolley

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

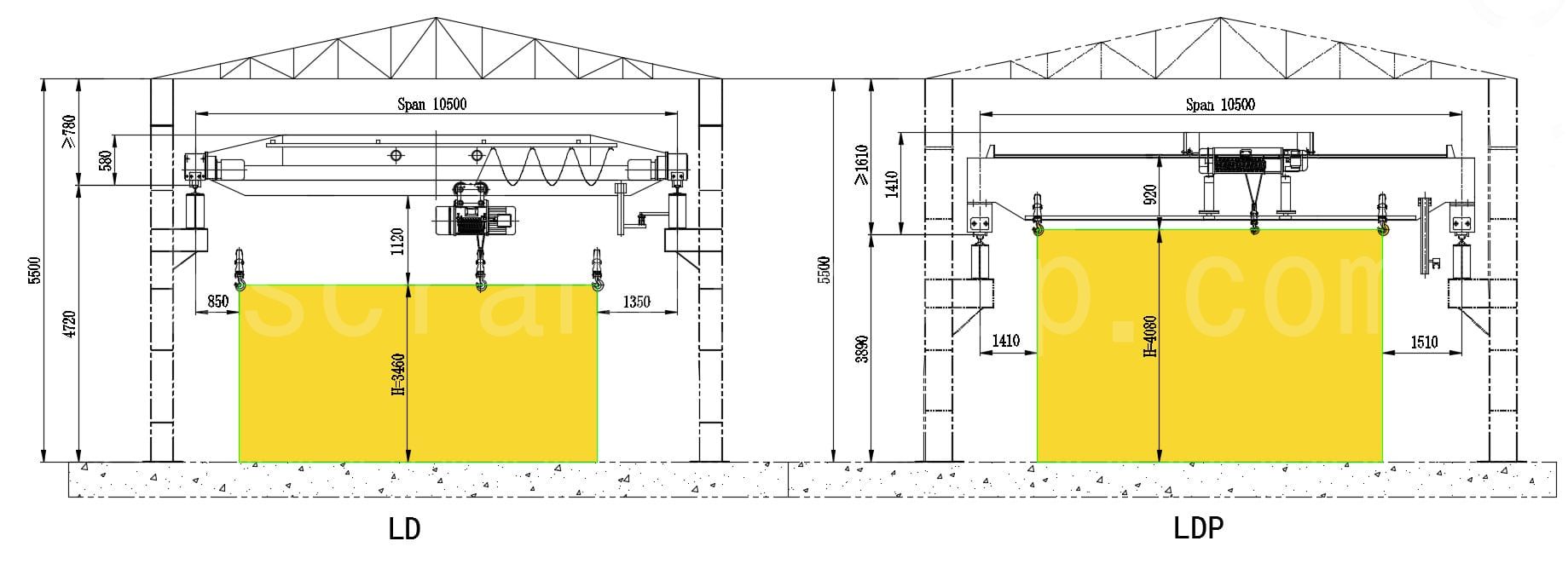

LDP Single Girder Offset Overhead Crane: Maximize Workshop Height with Smart Design

LDP electric single girder offset overhead crane belongs to ultra-low headroom light crane, electric hoist is located on the side of the main girder, which increases the working space of the hook and can reduce the height and cost of the plant. It is suitable for places with low headroom in workshops and plants.

- Span: 7.5~22.5m(non-standard design is available according to customer’s requirement).

- Working class: A3

- Working Environment: Temperature -20℃~+40

Single Beam Offset Bridge Crane Structure

Single girder offset overhead crane consists of a box-shaped main beam welded by steel plate, end beam, trolley, and running mechanism, the trolley consists of a running end beam, trolley frame, and stationary electric hoist, adopting the form of bias hanging, running on the side of the main beam, the trolley is equipped with upper and lower horizontal wheels, and the vertical walking wheel is arranged in three points. The position of the electric hoist is elevated from the traditional under the main beam to the upper side of the main beam, which effectively improves the lifting height.

- The trolley runs as a cone-type motor brake, open gear drive.

- The main girder is box-type structure, off-rail, with horizontal wheels on the top and bottom, which is safe and reliable and prevents the gnawing of rails.

- The trolley is driven by conical motor braking and open gear transmission. Running motor can be selected according to user requirements of soft start motor and frequency conversion speed control, crane start smoothly, safe and reliable operation.

- The operation mode is equipped with a ground handle or wireless remote control.

Single Girder Offset Overhead Crane Main Beam Internal Joint Robot Welding Line

- Compared with manual work, the welds formed by the robot are excellent in shape, the weld width is uniform, the surface is flat, and the defect is basically zero.

- Due to the uniform width of the weld, the damage caused by the stress concentration on the weld is greatly reduced, and the average weld height is higher than that of the artificial weld, which greatly improves the strength of the product.

LDP Offset Overhead Crane VS LD Overhead Crane

LDP type electric single girder offset overhead crane is a girder crane with angular trolley structure. Compared with LD type electric single girder overhead crane, it has better utilization of height space. This structure is often used in the case where the elevation of the trolley track in the workshop is low, but the headroom between the top surface of the track and the lowest point of the workshop is large. This structure can better utilize the height space inside the workshop, and can effectively raise the hoist lifting height.

Custom Single Girder Offset Overhead Crane Case

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.