合理化された資材処理のための 5 つのワークステーション クレーン: 自立型からモノレールまで

スチール製またはアルミニウム製のワークステーション リフティング システムは、従来のクレーンに対する業界の認識を変えました。ワークステーション クレーンの設計は軽量で、組み立てが簡単で、人間工学に基づいており、作業効率が革命的に向上し、よりコスト効率の高い選択肢を提供します。

ワークステーションクレーンの種類

自立型ワークステーション橋形クレーン

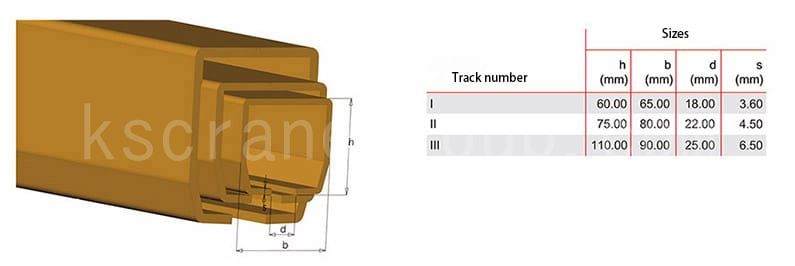

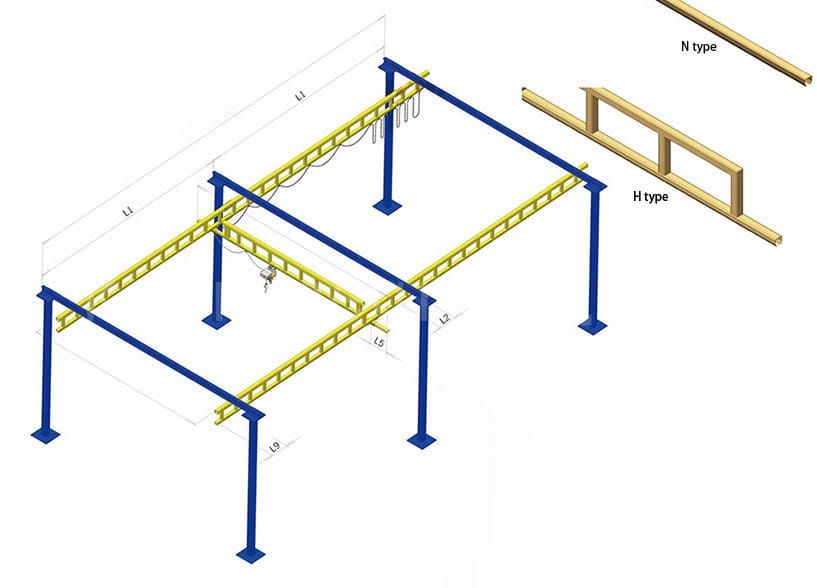

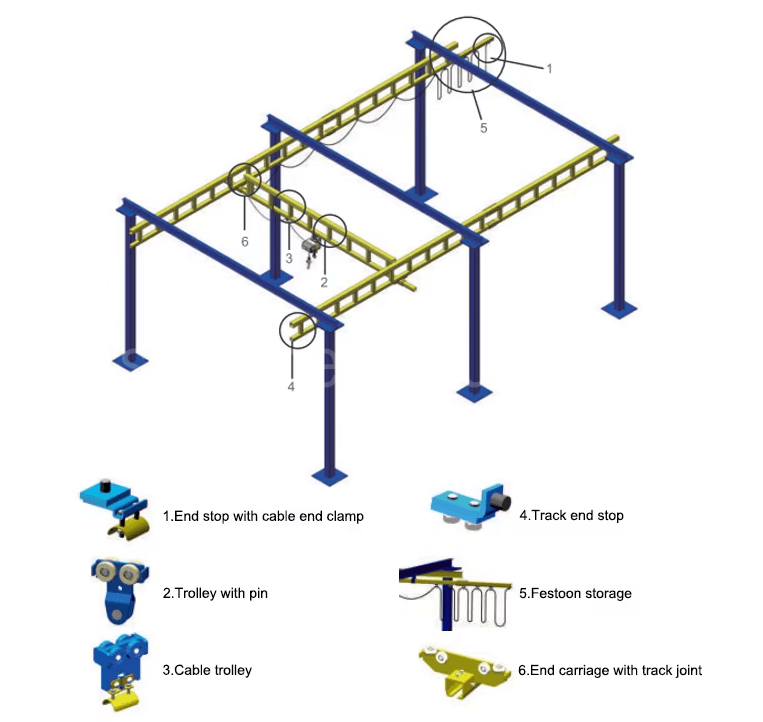

自立型ワークステーションクレーンは、高強度で軽量な密閉型レールで設計されたC型レールを採用しており、レール台車とホイスト台車の摩耗を効果的に減らすことができます。吊り上げポイントが不十分な場合は、トラス型鋼レールを使用してレールの支持を強化し、より大きなスパンを実現できます。

自立型ワークステーションブリッジクレーンの利点

- クローズドレール、断面溶接なし、優れた性能、6mあたり±1mmの真直度。

- 下端の 2° 開口設計により、トロリーが自動的にセンタリングされ、よりスムーズに走行します。

- レールは、完全なプロセス品質管理機能を備えた国内の高度な特殊レール圧延システムによって圧延されます。

自立型ワークステーション橋形クレーンの仕様

当社の 3 つのサイズのトラックは、最大 2000 kg までの幅広い荷重に適しています。トラックの傾斜設計により、トロリーがトラック内で直線的に走行し、トラック内のほこりの蓄積が軽減されます。これにより、トロリーがトラック内でスムーズに走行し、トラックの寿命が延びます。これにより、軽量クレーンを操作するために必要な荷重吊り上げ能力は 1-4% のみになります。

| 定格荷重(kg) | トラック番号 | 主梁スパン(mm) | L1最大(mm) | L2最大(mm) | L5 最大(mm) | L9最大(mm) |

|---|---|---|---|---|---|---|

| 250 | で | 2500 | 1900 | 1200 | 600 | 1200 |

| IH | 10000 | 9000 | 1200 | 600 | 1200 | |

| 500 | II-N | 2500 | 1800 | 1200 | 600 | 1200 |

| II-H | 10000 | 9000 | 1200 | 600 | 1200 | |

| 1000 | III-N | 3000 | 2000 | 1200 | 600 | 1200 |

| III-H | 10000 | 9000 | 1200 | 600 | 1200 | |

| 2000 | III-H | 9000 | 8000 | 1200 | 600 | 1200 |

自立型ワークステーション橋形クレーンの詳細

自立型ワークステーション橋形クレーン設置フォーム

スペースの制約を解決し、従来範囲を超えた材料のクロス輸送

ワークステーションサイズの材料持ち上げの不適合性を移動クレーンで解決

既存のスペース制約と持ち上げスペースの不足を解決

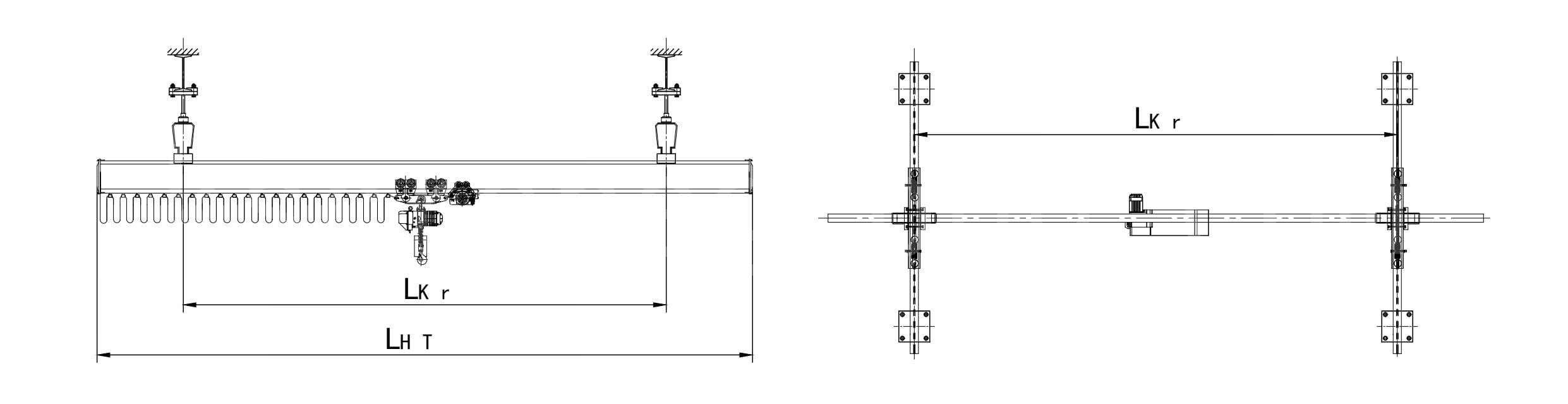

ダブルガーダー吊り下げ式ワークステーション橋形クレーン

ダブルガーダー吊り下げ式ワークステーションクレーンは、高荷重容量を備えており、重量物の持ち上げに広く使用されています。さまざまな商品を簡単に輸送できます。エリアおよびオーバーヘッドハンドリングを実行でき、重量物や大きなスパンでも、高速で信頼性が高く正確な位置決めを保証します。ホイストは、2 つのメインビームセクションの間に配置され、持ち上げスペースを最大限に活用します。

ダブルガーダー吊り下げ式ワークステーションクレーンシステムの利点

- 高所・面荷重輸送

- スタンドオフ距離が短いため、スペースを最大限に活用できます。

- シンプルで安全、そして信頼性の高い取り扱い

- 優れた設置寸法

- 限られたエリアでも、顧客のワークショップの要件に合わせてコスト効率の高いソリューションをカスタマイズできます。

- モジュール式システム設計による幅広いアプリケーション

- マニピュレータ クレーンとしても使用可能 - 高度なハンドリング システムに最適な設計です。

- 定格吊り上げ能力は最大3200kg

- ホイストは、フックストロークを最大化するために、メインクレーンガーダーの間に取り付けられています。

- 複数のハンガー(2つ以上のトラックで走行するクレーン)を使用することでスパンを最大化し、広い保管エリアと生産エリアをカバーできます。

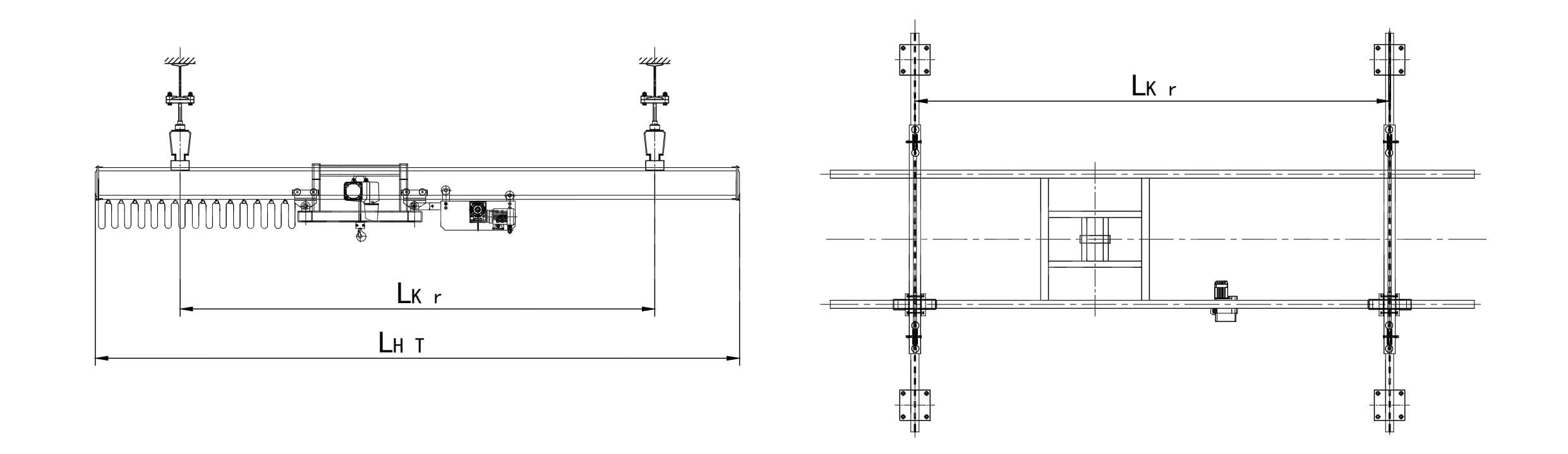

ダブルガーダー吊り下げ式ワークステーションクレーンシステムのパラメータ

| トラック番号 | 自重(kg) | |||||||

| 125 | 250 | 500 | 1000 | 1600 | 2000 | 3000 | ||

| Ⅱ | らクル(分) | 10.0 | 10.0 | 8.5 | 6.2 | 4.6 | 3.65 | |

| らHT | 12.0 | 12.0 | 11.5 | 7.0 | 5.0 | 4.0 | ||

| II-T(標準) | らクル(分) | 10.5 | 10.5 | 10.5 | 9.1 | 7.4 | 6.7 | お問い合わせください |

| らHT | 14.0 | 14.0 | 14.0 | 12.0 | 9.0 | 7.0 | お問い合わせください | |

最小カンチレバー長さ 125 mm

顧客の要件に応じてカスタマイズ可能

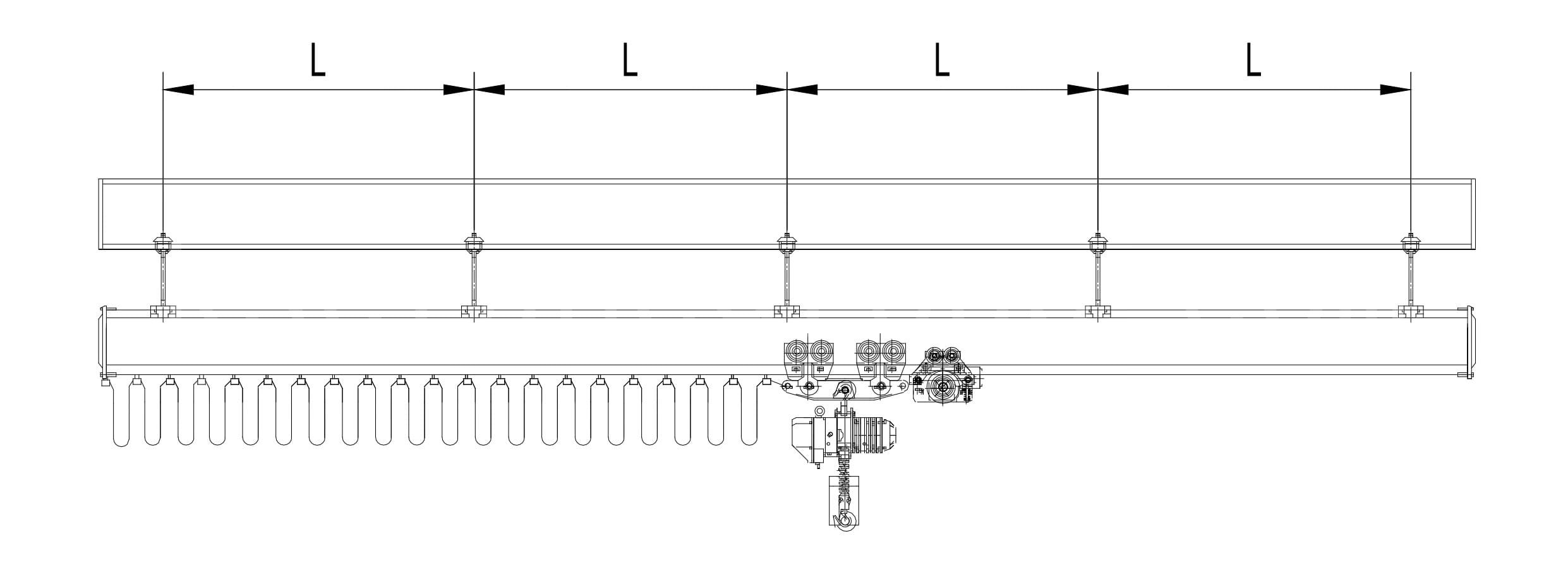

シングルガーダー吊り下げ式ワークステーション橋形クレーン

シングルガーダー吊り下げ式ワークステーション 橋クレーン 優れた設計で、高レベルの輸送に非常に信頼性があります。シングル ガーダー吊り下げ式ワークステーション クレーン システムは、動作半径が大きく、荷物の揺れ現象を軽減でき、特定の領域で高速かつ信頼性が高く、さまざまな商品の頭上処理と正確な位置決めが可能で、高効率、省電力、省エネ、総面積が小さい、使いやすくメンテナンスが簡単などの特性があります。

シングルガーダー吊り下げ式ワークステーションクレーンシステムの利点

- 手動で簡単に移動可能、軽量

- クレーン本体とトロリー間の連結によりスムーズでトラブルのない操作が可能

- 限られたスペースでも、お客様の作業場の要件に合わせてカスタマイズされた費用対効果の高いソリューション

- モジュール式システム設計による幅広いアプリケーション

- クレーンは非平行軌道でも操作可能

- スペースを最大限に活用

- 高所・面荷重輸送

- スタンドオフ距離が短いため、理想的なスペース利用が可能

シングルガーダー吊り下げ式ワークステーションクレーンシステムのパラメータ

| トラック番号 | 自重(kg) | |||||||

| 80 | 125 | 250 | 500 | 1000 | 1600 | 2000 | ||

| Ⅱ | らクル(分) | 7.75 | 7.75 | 7.45 | 6.0 | 3.5 | ||

| らHT | 8.0 | 8.0 | 8.0 | 7.0 | 4.0 | |||

| II-T(標準) | らクル(分) | 10.5 | 10.5 | 9.3 | 6.5 | |||

| らHT | 14.0 | 13.0 | 11.0 | 7.0 | ||||

最小カンチレバー長さ 125 mm

顧客の要件に応じてカスタマイズ可能

モノレールクレーン

モノレール クレーンは、直線的な空中ハンドリング作業の特定のニーズに合わせたソリューションを提供します。さまざまなオプションを組み合わせることで、独自の利点を実現できます。モノレールは、当社のすべての吊り上げ装置に適しており、重量物の吊り上げと移動のための汎用ソリューションを提供します。標準の接続と留め具により、簡単に組み立てることができます。モジュール設計により、生産条件が変わったときに簡単かつ迅速に変更を加えることができます。

モノレールクレーンの利点

- シンプルで手動操作可能な直線セクション - アルミニウムプロファイルも利用可能

- 最大3200kgの持ち上げ能力

- 直線レール、曲線レール、分岐器、ターンテーブルを組み合わせることで、線路を柔軟に調整できます。

- 逆操作または閉回路での把持点と配置点の直接接続が可能

- 手動操作に加えて半自動または全自動操作

- 複合設備は、さまざまなコンポーネントを組み合わせて使用することで、さまざまなワークショップのさまざまな構造要件にルートを正確に適応させることができます。

- ロック装置を使用して隣接する吊り下げクレーンに移送することもできます

- 機器キャリアとして使用可能(例:試験機器、動力および風力ツール用)

- 包括的な KBK コンポーネント システムは、クレーンやその他の移動機器の流体システム、圧縮空気システム、電源システムの輸送に信頼性の高い中間キャリア (ケーブル トロリー、ホース クランプなど) を提供します。

- マニピュレーターや昇降装置などの剛性ハンドリング機器のキャリアとしてのデュアルレールレールシステム。

モノレールクレーンパラメータ

| トラック番号 | 自重(kg) | ||||||

| 125 | 250 | 500 | 1000 | 1600 | 2000 | ||

| Ⅱ | LW(最大) | 6.0 | 4.0 | 2.5 | 2.4 | 1.2 | |

| II-T(標準) | LW(最大) | お問い合わせください | お問い合わせください | お問い合わせください | お問い合わせください | お問い合わせください | |

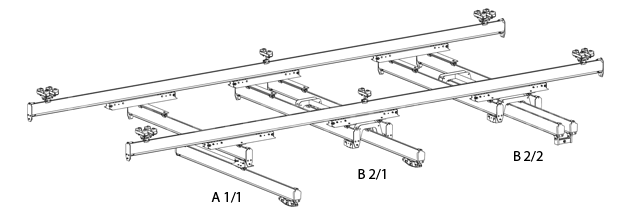

クレーンの延長

ワークステーションの吊り上げシステムの有効範囲が支持構造の限界を超える必要がある場合は、延長メイン ビームをより深く使用できます。延長式および伸縮式ガーダー クレーンを使用すると、クレーン トラックを超えて荷物を移動できます。このソリューションにより、スペースをより効率的に使用でき、利用可能なスペースを理想的な効率で活用できます。当社のソリューションは、特定のニーズを満たします。延長クレーンは、コンテナやトラックで使用されることが多く、自動車産業ではツール レールで使用される場合もあります。

クレーンのメリットを拡張

- クレーンの主桁に取り付けられた伸縮クレーンは、クレーントラックの幅を超えて延長することができます。

- 伸縮クレーンは、固定部分と両方向に伸縮可能なクレーン部分で構成されています。

- 主クレーンの桁はレールのスパンを超えて最大 2500 mm まで延長できます。

- 設計に応じて、主桁は片方向または両方向にクレーン軌道の幅を超えて延長できます。

- 簡単にアクセスできない領域(柱の間など)に荷物を正確に持ち上げて配置するために使用できます。

- ワークショップスペースの効率的な利用(例えば、ワークショップを後で拡張する場合、追加のクレーンレールなしで新しいエリアをカバーできます)

- 排気管、暖房ダクト、ケーブルの下でも作動可能

クレーンの伸縮説明図

お問い合わせ

- 製品の無料で迅速な見積もり。

- 製品カタログを提供します。

- 私達の会社からのあなたのローカル クレーン プロジェクト。

- 私たちのエージェントになって手数料を稼ぎましょう。

- ご不明な点がございましたら、お問い合わせください。