LD 普通型と LDC 低天井シングル ガーダー天井クレーンの比較: ポンプ室設備のアップグレード成功事例から学ぶ教訓

目次

産業機器のアップグレードや技術変革プロジェクトでは、適切なクレーンを選択することが、効率性だけでなく、プロジェクト全体のコストとスケジュールにとっても重要です。多くのお客様にとって、適切な吊り上げ装置を選択するには、複雑な技術的パラメータとコストの考慮事項のバランスを取る必要があり、決定プロセスは困難で時間がかかります。しかし、私たちは、すべてのプロジェクトには独自のニーズがあると確信しています。これらのニーズに応えるため、当社のソリューションは効率的であるだけでなく、コスト効率も非常に優れています。

実際のプロジェクト事例を比較すると、 LDトップランニングシングルガーダー天井クレーン と LDC 低天井シングルガーダー天井クレーンこのプロジェクトを通じて、特定の要件に合わせてソリューションをカスタマイズする方法を説明します。

プロジェクトの背景: ポンプ室設備のアップグレードにおける課題の克服

私たちは、廃水処理プラントの技術変革プロジェクトを依頼されました。クライアントとの最初の話し合いで、既存の設備のアップグレードが大きな課題に直面していることが明らかになりました。現在の LD 5t-S10.5m A3 電動シングルガーダー天井クレーンでは、新しい設備の吊り上げ要件を満たすことができなくなっていたのです。

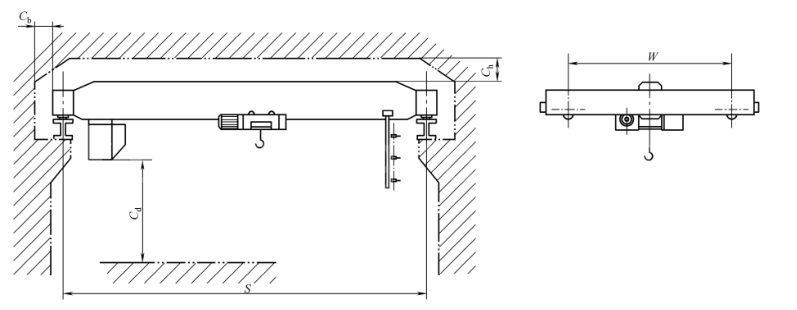

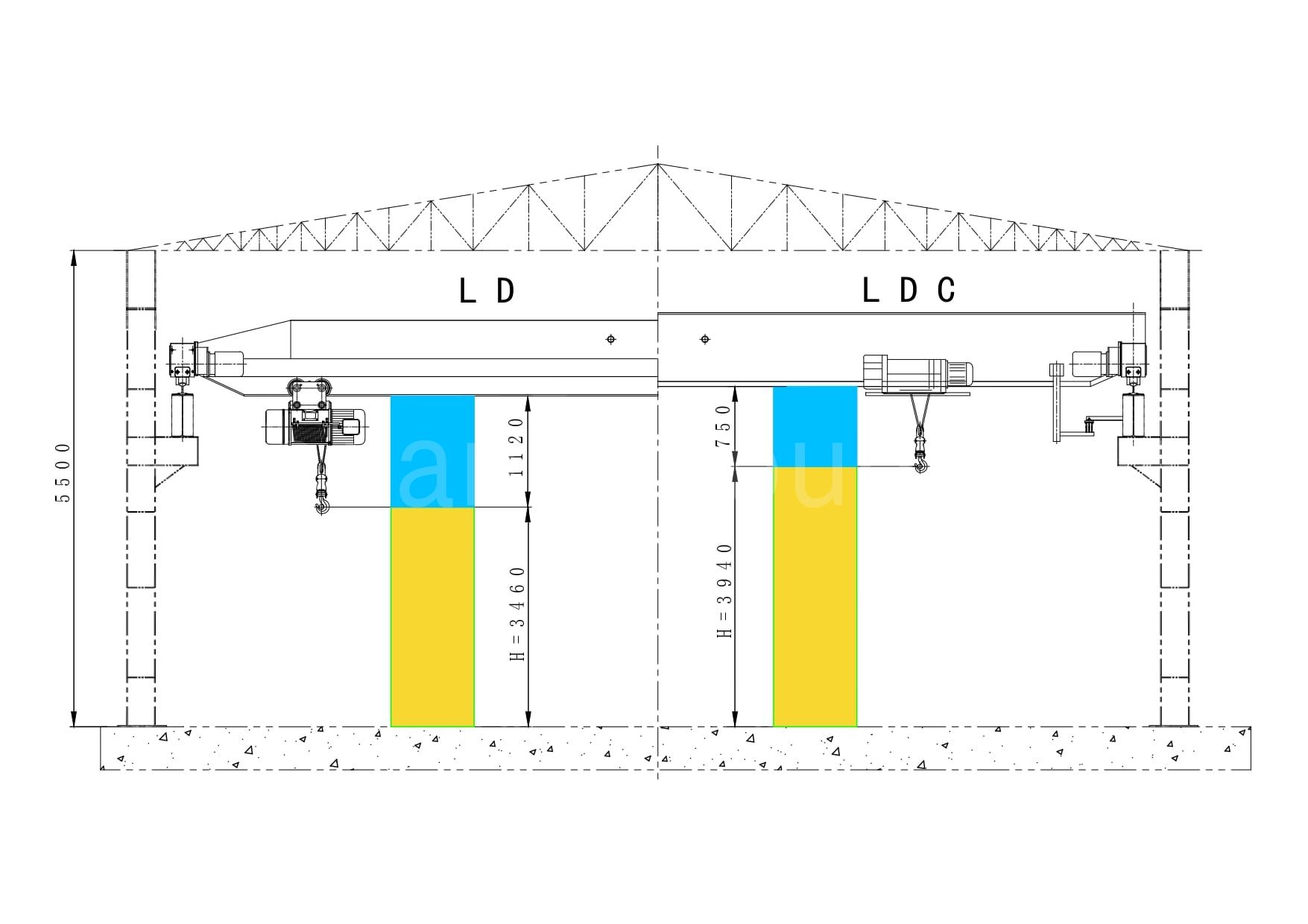

新しい大型ポンプシステムは、元のポンプに比べてサイズと重量が大幅に増加しました。ポンプの高さは 300 mm 増加し、重量は 220 kg 増加しました (元の重量 3,570 kg から)。既存のクレーンの揚高は 3.46 メートルでしたが、新しい機器を適切に設置するには少なくとも 3.76 メートルの揚高が必要でした。そのため、クレーンのアップグレードは避けられませんでした。

お客様と何度も話し合い、ポンプ室のスペース、設備のレイアウト、予算上の制約を詳細に分析した後、現在の LD シングル ガーダー天井クレーンを LDC ロー ヘッドルーム シングル ガーダー天井クレーンに置き換えることを提案しました。LDC ロー ヘッドルーム シングル ガーダー天井クレーンの揚程は 3.94 メートルで、既存のクレーンより 480 mm 向上し、設置要件を完全に満たしています。さらに、新しいポンプの重量増加は中程度であったため、既存のワークショップのクレーン ビーム システムを交換する必要がなく、お客様の改造コストを大幅に削減しました。

LD シングルガーダークレーンと LDC ローヘッドルームシングルガーダークレーン

LD シングル ガーダー オーバーヘッド クレーンと LDC ロー ヘッドルーム シングル ガーダー オーバーヘッド クレーンは、産業分野で一般的に使用されており、それぞれに独自の利点があります。プロジェクトに適したクレーンを選択するにはどうすればよいでしょうか。いくつかの重要な側面で比較してみましょう。

1. 構造上の特徴

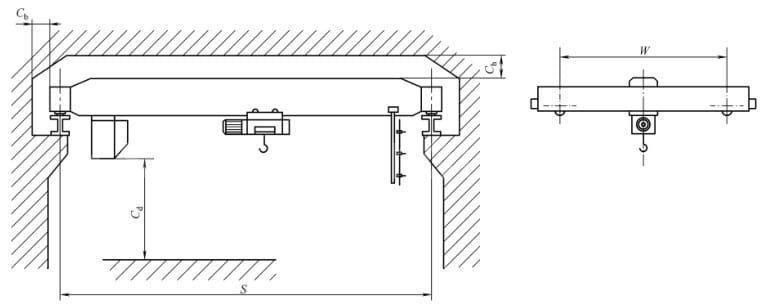

LD シングルガーダー天井クレーン:

LD シングル ガーダー天井クレーンは、主にメイン ガーダー、エンド ビーム、電動ホイスト、トロリー機構、および電気機器で構成されています。

- 主桁: I ビーム ボックス型設計を採用しています。I ビームのフランジには一定の傾斜があり、従来のホイスト トロリーの車輪と一致しています。

- エンドビーム: モーター、減速機、車輪セット、ゴム緩衝器を装備。

- 電気機器: 周波数 50Hz または 60Hz、電圧 220V ~ 660V の三相交流で動作します。電源には安全スライドワイヤまたはケーブルトロリーを使用し、電気保護システムを内蔵しています。

- 電気ホイスト: 通常は CD1 または MD1 電動ホイストと組み合わせて使用します。

LDC 低天井シングルガーダー天井クレーン:

LDC 低天井シングル ガーダー天井クレーンには、メイン ガーダー、エンド ビーム、低天井電動ホイスト、トロリー機構、および電気機器が含まれます。

- 主桁: 鋼板を溶接した箱型構造物。桁下部のフランジがトロリーの軌道となる。フランジが平らなため、トロリーの車輪は円筒状の平面で設計されている。

- エンドビーム: LD シングル ガーダー天井クレーンに類似しており、モーター、減速機、ホイール セット、ゴム バッファーが付属しています。

- 電気機器: LDシングルガーダー天井クレーンと同じ動力・保護システムを備えています。

- 電気ホイスト:低天井タイプの電動ホイスト。

2. 揚程とクリアランスの設計

- LDシングルガーダー天井クレーン: 標準的な天井高の作業場での用途に最適です。吊り上げ機構は主桁の下に設置されており、フックのクリアランス高さが制限されます。作業場の高さが十分にある場合は、LD シングル桁天井クレーンは経済的で効率的な選択肢です。

- LDC 低天井シングルガーダー天井クレーン: 天井高が限られたスペース向けに特別に設計されています。低天井高設計により、吊り上げ機構がメインガーダーの上に配置されるため、吊り上げ高さが最大になります。このため、LDC 低天井高シングルガーダー天井クレーンは、クリアランスが問題となる狭い作業場、技術的な改修、または古い工場のアップグレードに最適です。

ケースレビュー: 廃水処理プラント プロジェクトでは、ポンプ室の高さ要件を満たす能力があるため、LDC 低天井シングル ガーダー天井クレーンは最適な選択でした。これにより、揚高の問題が解決されただけでなく、作業場の構造変更に関連するクライアントの追加コストも節約されました。

3. 応用シナリオ

- LDシングルガーダー天井クレーン一般的な機械製造、倉庫、組立ラインなど、高さが十分で持ち上げ高さが低いことが求められる作業場でよく使用されます。

- LDC 低天井シングルガーダー天井クレーン: 技術的な改修、古い工場のアップグレード、天井の低い作業場など、スペースが限られたプロジェクトや、特定の持ち上げ高さの要件がある状況に適しています。

4. 設置および保守コスト

- LDシングルガーダー天井クレーン: 設置が簡単でコスト効率に優れているため、標準的な用途に最適です。 持ち上げ高さやクリアランスに厳しい要件がない場合は、LD シングル ガーダー オーバーヘッド クレーンは優れた価値を提供します。

- LDC 低天井シングルガーダー天井クレーン: 設置コストは若干高くなりますが、限られたクリアランススペースを有効活用できます。これにより、大規模な構造変更が不要になり、長期的には大幅なコスト削減につながります。

顧客からのフィードバック: 当社の経験では、お客様は当初、LDC 低天井シングル ガーダー天井クレーンのコストに躊躇するかもしれません。しかし、クリアランスの利点と長期的なメンテナンスの利便性を理解した後、総所有コストが予想よりもはるかに低いと多くのお客様が報告しています。

5. 比較パラメータ

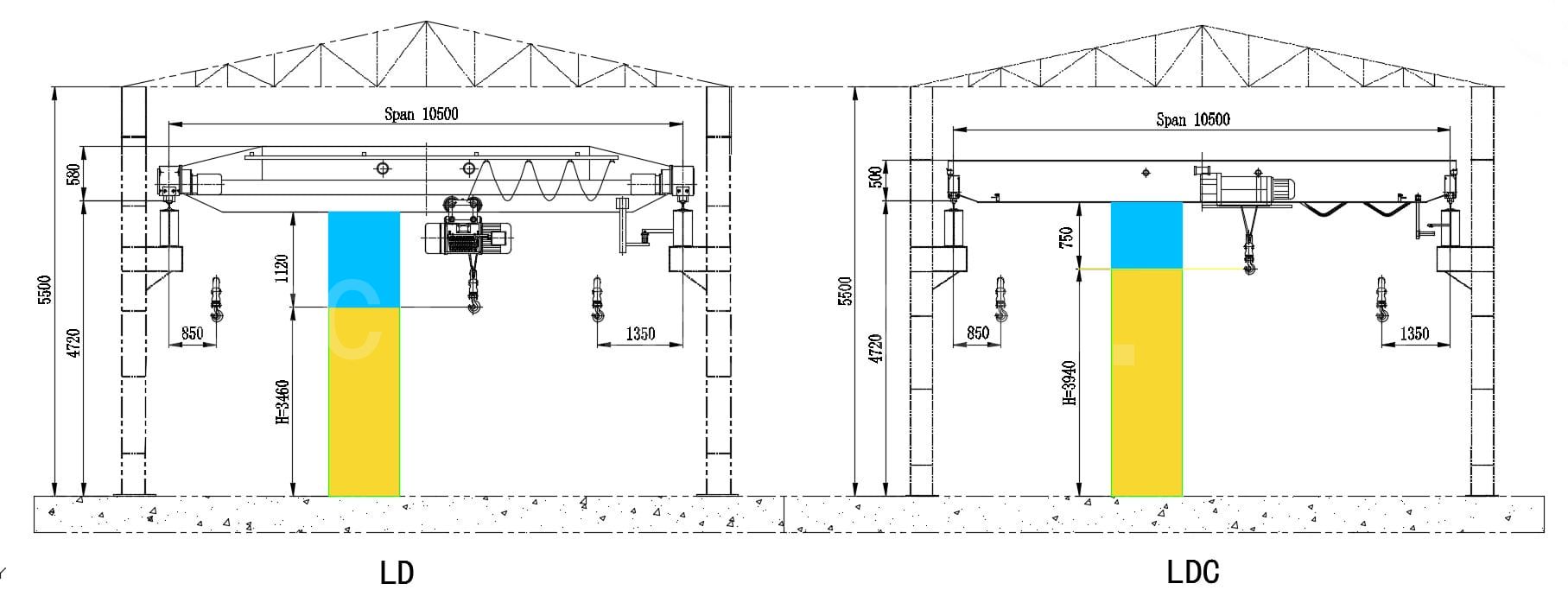

同じ工場クリアランス寸法での LD シングル ガーダー天井クレーンと LDC シングル ガーダー天井クレーンのさまざまなパラメータの比較は次のとおりです。

| パラメータ | LDモデル | LDC モデル |

|---|---|---|

| 工場出荷時のクリア高さ (mm) | 5500 | 5500 |

| クレーンレール高さ(mm) | 4720 | 4720 |

| レールから天井までの正味スペース(mm) | ≥780 | ≥700 |

| 有効揚程(mm) | 3460 | 3940 |

| ホイストフック限界(mm) | 1120 | 750 |

| フック左/右限界(mm) | 850/1350 | 850/1350 |

| 総重量(kg) | 2720 | 3120 |

| 輪荷重 (KN) | 35 | |

| 機器価格(人民元、10,000人民元) | 2.32 | 3.05 |

お客様との複数回の話し合いを通じて、私たちはお客様の設備ニーズに焦点を当てるだけでなく、作業場の構造特性、予算の制約、将来の使用シナリオも考慮しました。私たちは、LDC 低天井シングル ガーダー天井クレーンを推奨しました。これにより、お客様の揚程の問題が解決されただけでなく、不要な二次工事が回避され、プロジェクトの総コストが大幅に削減されました。

適切なクレーンを選択するための推奨事項

- プロジェクトに十分なスペースがあり、持ち上げ高さの要件が最小限である場合、LD シングル ガーダー天井クレーンが最もコスト効率の高い選択肢となります。

- スペースが限られているプロジェクトや、高い揚高が要求されるプロジェクトの場合、LDC 低天井シングル ガーダー オーバーヘッド クレーンは間違いなく最適なソリューションです。作業場の構造に影響を与えることなく、効率的な揚重能力を提供し、スペースを最大限に活用します。

結論: あらゆるプロジェクトに合わせたソリューション

LD シングル ガーダー天井クレーンでも、LDC ロー ヘッドルーム シングル ガーダー天井クレーンでも、当社のチームは常にお客様のニーズを最優先に考えます。すべてのプロジェクトは独自の課題とみなされ、包括的なニーズ分析とカスタマイズされたソリューションを通じて、細部に至るまでお客様の期待に応えます。

優れたサービスとは、製品を提供する以上のものだと私たちは考えています。それは、課題を克服し、カスタマイズされたソリューションで目標を達成することです。あなたのプロジェクトが同様の困難に直面している場合は、お気軽にお問い合わせください。最適なリフティング ソリューションをご提供します。

私たちの仕事は好きですか?シェアする