- KAGAMITAN

- mga espesyal na crane

- Crane ng Industriya

- Hoist at Winch Trolley

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Pag-aangat ng Electromagnet para sa Pagliko at Pag-hang sa Gilid

-

Pag-aangat ng Electromagnet para sa Makapal na Plate

-

Espesyal na Electromagnet para sa Pag-aangat ng mga Steel Plate

-

Pag-aangat ng mga Electromagnets para sa Pag-angat ng mga Steel Plate

-

Pag-aangat ng Electromagnet para sa Heavy Rail at Profiled Steel

-

Lifting Electromagnet para sa High Speed Wier(Coiled Bar)

-

Pag-aangat ng Electromagnet para sa Rebar at Steel Pipe

-

Lifting Electromagnet para sa Bundled Rebar at Profiled Steel

-

Lifting Electromagnet para sa Billet, Girder Billet at Slab

-

Lifting Electromagnet para sa Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs at Clamps

-

Crane Electromagnetic Lifting Magnets

- MGA BAHAGI NG CRANE

- Paglipat ng Cart

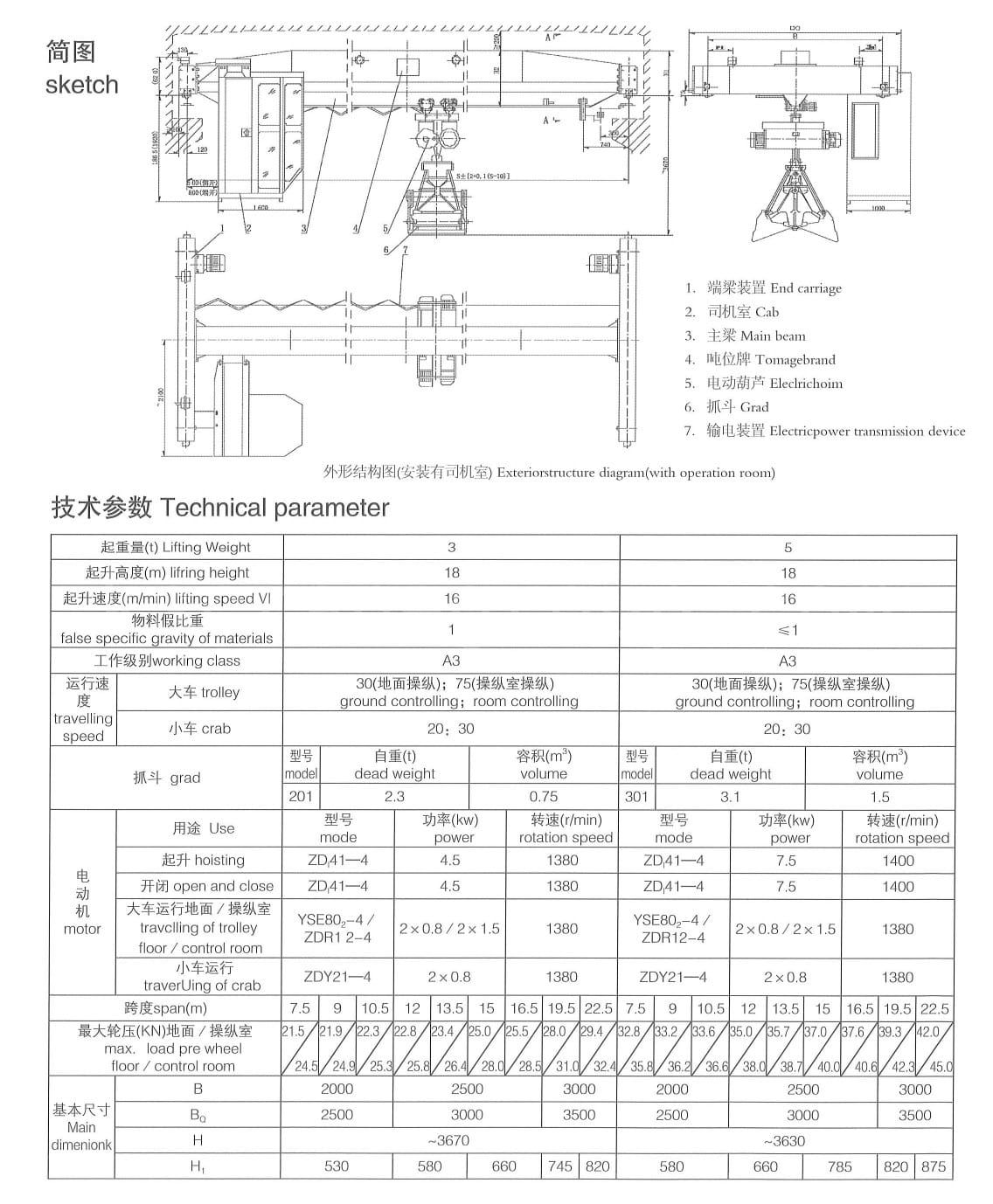

LDZ Single Girder Grab Overhead Crane: Napakahusay na Solusyon para sa Bulk Material Handling

Ang LDZ single girder grab overhead crane ay halos kapareho ng LD electric single girder overhead crane, tanging ang kunin ang balde iba ang mekanismo. Ang crane ay nilagyan ng grab lifting trolley at angkop para sa paghawak ng halos lahat ng maluwag at maramihang materyales tulad ng basura, pang-industriya na materyales at buhangin. Ang kapasidad ng pag-angat ng overhead crane ay mula 2 hanggang 10 tonelada at ang uring manggagawa ay A4. Ang crane na ito ay hindi maaaring gamitin sa mga nasusunog, sumasabog o nakakaagnas na kapaligiran. Ito ay perpekto para sa pag-aangat sa pagmimina, mga waste treatment plant, steel mill at power plant.

LDZ single beam grab bridge crane Structure

- Ang mga grab bridge cranes ay binubuo ng mga pangunahing bahagi tulad ng tulay, grab hoisting trolley, mekanismo ng pagpapatakbo ng crane at electrical control system.

- Tulay: Ang istrukturang metal na ito ay binubuo ng pangunahing girder at dulong girder. Ang pangunahing girder ay gumagamit ng istraktura ng kahon na binubuo ng U-channel at I-beam group.

- Crane trolley: lifting goods pati na rin ang unit na tumatakbo nang pahalang sa kahabaan ng tulay. Dalawang set ng electric hoists ang karaniwang naka-install sa trolley, isang set para sa pag-angat ng mga kalakal pataas at pababa, at ang isa pang set para sa pagbubukas at pagsasara ng grapple. Ang electric hoist ay pangunahing nahahati sa dalawang kategorya: wire rope hoist at hand-pull hoist, at ang dating ay mas malawak na ginagamit.

- Mekanismo ng pagtakbo ng kreyn: nagtutulak sa buong kreyn na magpabalik-balik sa runway beam. Ang mekanismo ng pagpapatakbo ay gumagamit ng hiwalay na drive mode, na kinukumpleto ng conical rotor na may brake motor o electromagnetic brake solid rotor motor. Ang bilis ng pagpapatakbo ay maaaring 20, 30, 45 m/min.

- Electrical control system: Ito ang yunit na nagbibigay ng kuryente para sa function ng crane. Dapat isaalang-alang ng disenyo ng electrical system ang ilang bagay tulad ng pagiging maaasahan, tibay at pag-iingat sa kaligtasan para sa pag-aangat.

Mga detalye ng single girder grab overhead crane

Single beam grab bridge crane main beam internal joint robot welding line

- Kung ihahambing sa manu-manong trabaho, ang mga hinang na nabuo ng robot ay mahusay sa hugis, ang lapad ng hinang ay pare-pareho, ang ibabaw ay patag, at ang depekto ay karaniwang zero.

- Dahil sa pare-parehong lapad ng hinang, ang pinsala na sanhi ng konsentrasyon ng stress sa hinang ay lubos na nabawasan, at ang average na taas ng hinang ay mas mataas kaysa sa artipisyal na hinangin, na lubos na nagpapabuti ng lakas ng produkto.

Kaso

Single Girder Grab Overhead Cranes para sa Breweries

Makipag-ugnayan

- Libre at mabilis na quote para sa produkto.

- Ibigay sa iyo ang aming katalogo ng produkto.

- Ang iyong lokal na proyekto ng crane mula sa aming kumpanya.

- Maging aming ahente at kumita ng komisyon.

- Anumang mga katanungan, makipag-ugnayan sa amin.