- KAGAMITAN

- mga espesyal na crane

- Crane ng Industriya

- Hoist at Winch Trolley

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Pag-aangat ng Electromagnet para sa Pagliko at Pag-hang sa Gilid

-

Pag-aangat ng Electromagnet para sa Makapal na Plate

-

Espesyal na Electromagnet para sa Pag-aangat ng mga Steel Plate

-

Pag-aangat ng mga Electromagnets para sa Pag-angat ng mga Steel Plate

-

Pag-aangat ng Electromagnet para sa Heavy Rail at Profiled Steel

-

Lifting Electromagnet para sa High Speed Wier(Coiled Bar)

-

Pag-aangat ng Electromagnet para sa Rebar at Steel Pipe

-

Lifting Electromagnet para sa Bundled Rebar at Profiled Steel

-

Lifting Electromagnet para sa Billet, Girder Billet at Slab

-

Lifting Electromagnet para sa Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs at Clamps

-

Crane Electromagnetic Lifting Magnets

- MGA BAHAGI NG CRANE

- Paglipat ng Cart

3 Mahusay na Electromagnetic Overhead Crane na may Lifting Beam para sa Steel Plate, Bundle, at Billet Handling

Ang electromagnetic overhead crane na may lifting beam ay pangunahing ginagamit sa tuluy-tuloy na casting extraction span, tuluy-tuloy na rolling workshop, o mga bodega ng tapos na produkto. Kasama sa kapasidad ng pag-angat ang bigat ng sinag, electromagnet, at ang materyal na inaangat. Nagmumula ito sa iba't ibang anyo ng istruktura, karaniwang kabilang ang mga pangkalahatang electromagnetic bridge crane na may lifting beam, rotating trolley electromagnetic overhead crane na may lifting beam, at electromagnetic overhead crane na may umiikot na lifting beam. Available din ang pagpapasadya ayon sa mga kinakailangan ng customer.

Electromagnetic overhead crane na may lifting beam

Ang electromagnetic overhead crane na ito na may mga lifting beam ay nilagyan ng naaalis na electromagnetic disk, na ginagawa itong partikular na angkop para sa paghawak ng mga ferromagnetic na produkto at materyales tulad ng mga steel ingots, structural steel, at pig iron blocks. Pangunahing ginagamit ito sa mga gilingan ng bakal, mga bodega ng tapos na produkto, mga bakuran ng bakal, at mga pagawaan ng pagputol.

Pagtutukoy

Mga kaso

Ang QL10+10T automated electromagnetic overhead crane na may lifting beam ay ginagamit para sa pagdadala ng mga cast pipe.

Batay sa tradisyonal na electromagnetic overhead crane na may mga lifting beam, ang Henan Kuangshan ay nag-customize, nag-develop, at gumawa ng isang automated steel plate transport electromagnetic overhead crane na partikular para sa Sany Heavy Industry.

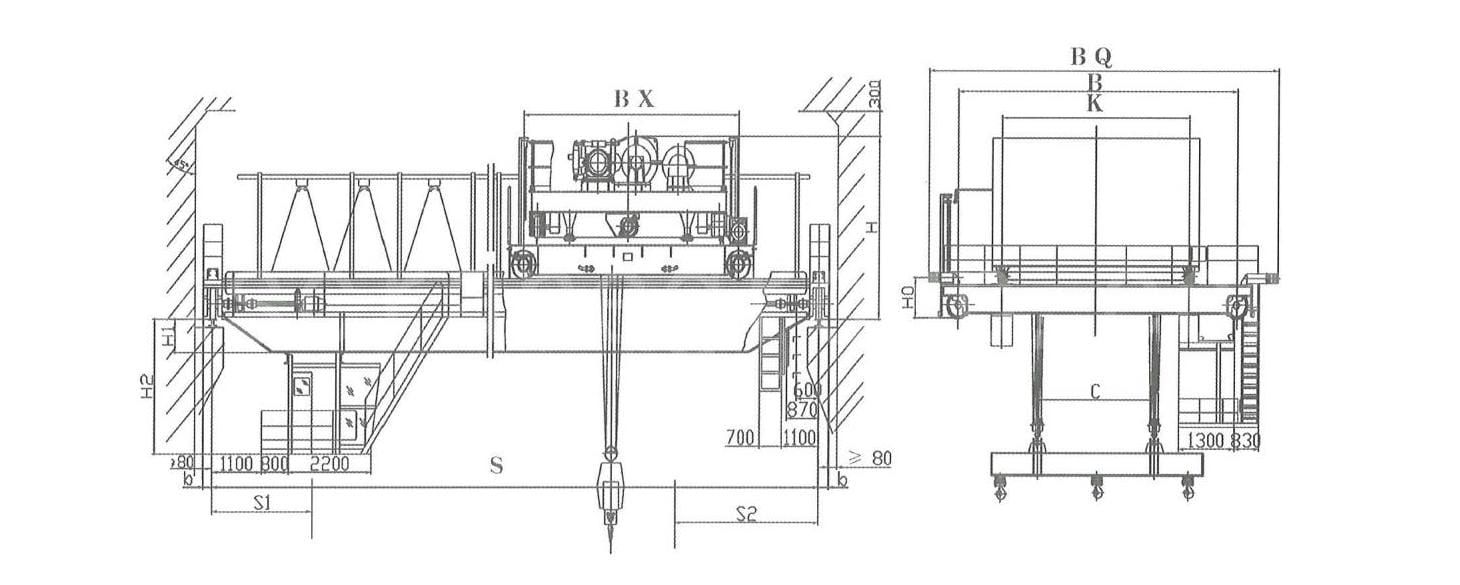

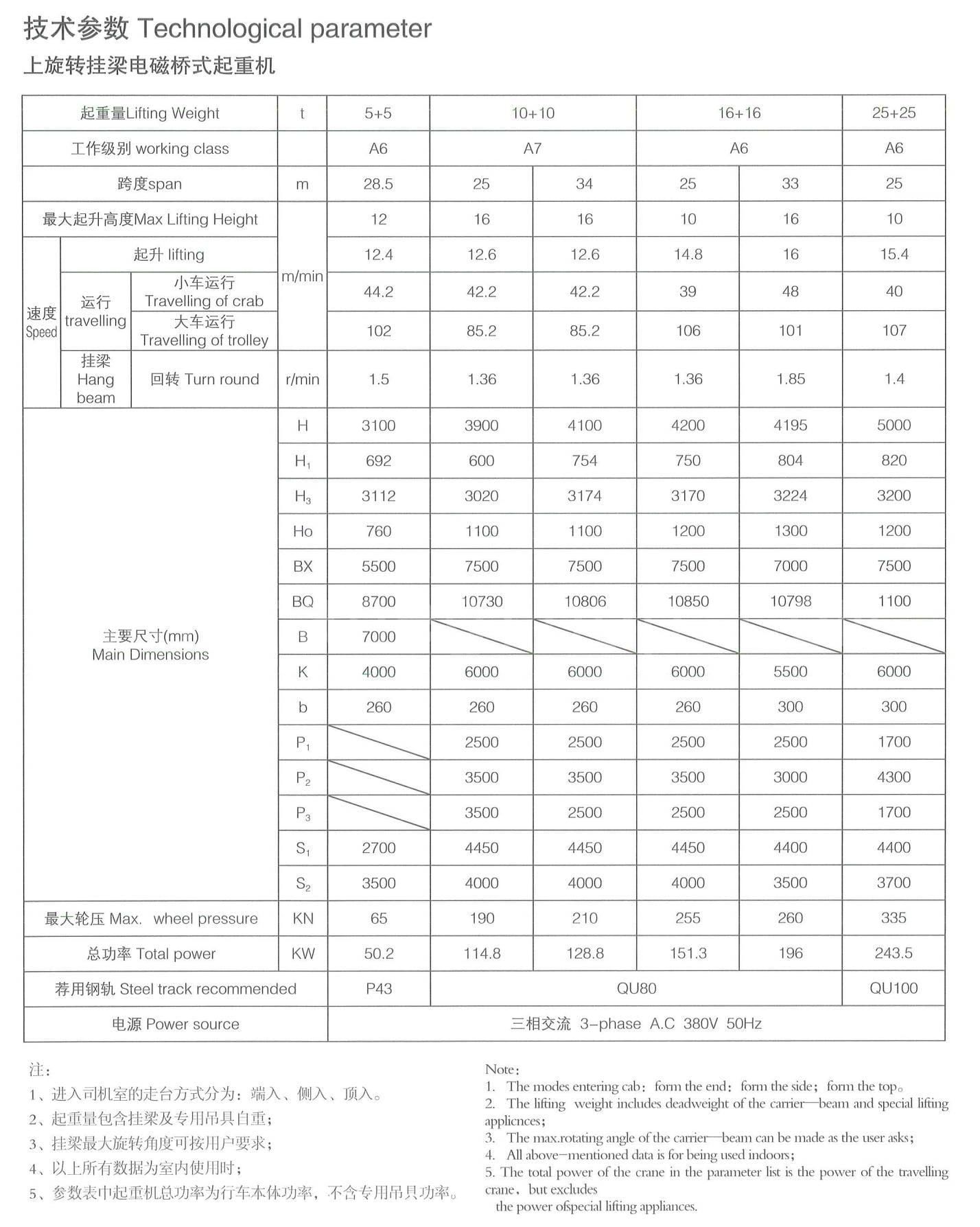

Umiikot na trolley electromagnetic overhead crane na may lifting beam

Ang umiikot na trolley electromagnetic overhead crane na ito na may lifting beam ay nilagyan ng rotatable hanging beam, kaya angkop itong gamitin sa mga fixed span sa steel mill, storage yards, at warehouses, sa loob at labas ng bahay. Dinisenyo ito para sa pagkarga, pagbabawas, at pagdadala ng mga materyales tulad ng mga bakal na plato, structural steel, at coils. Ito ay partikular na angkop para sa pag-angat ng mga materyales ng iba't ibang mga pagtutukoy na nangangailangan ng pahalang na pag-ikot.

Pagtutukoy

Umiikot na trolley electromagnetic overhead crane na may lifting beams diagram

Umiikot na trolley electromagnetic overhead crane na may parameter ng lifting beam

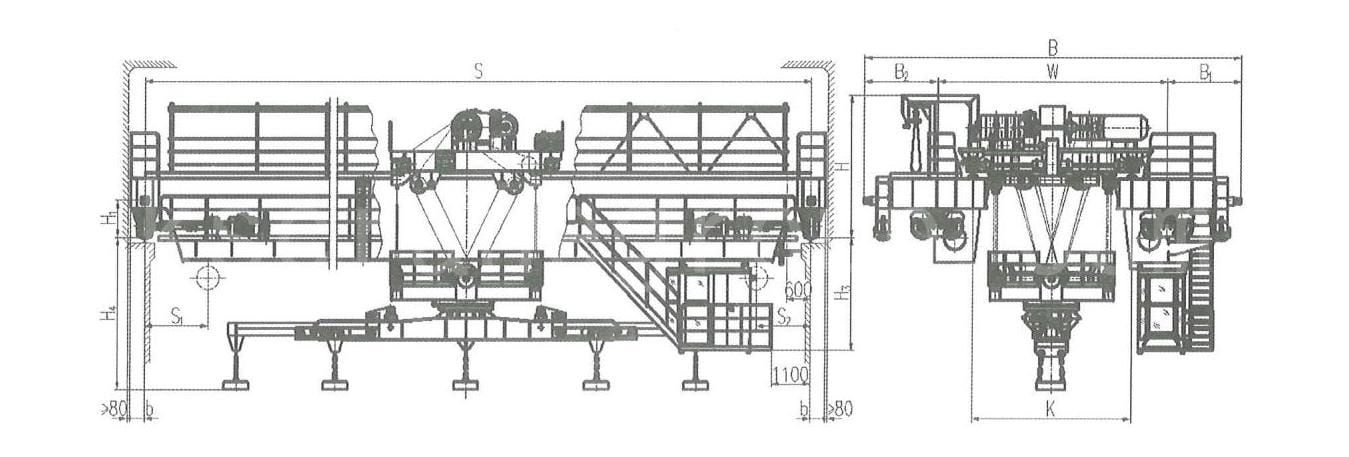

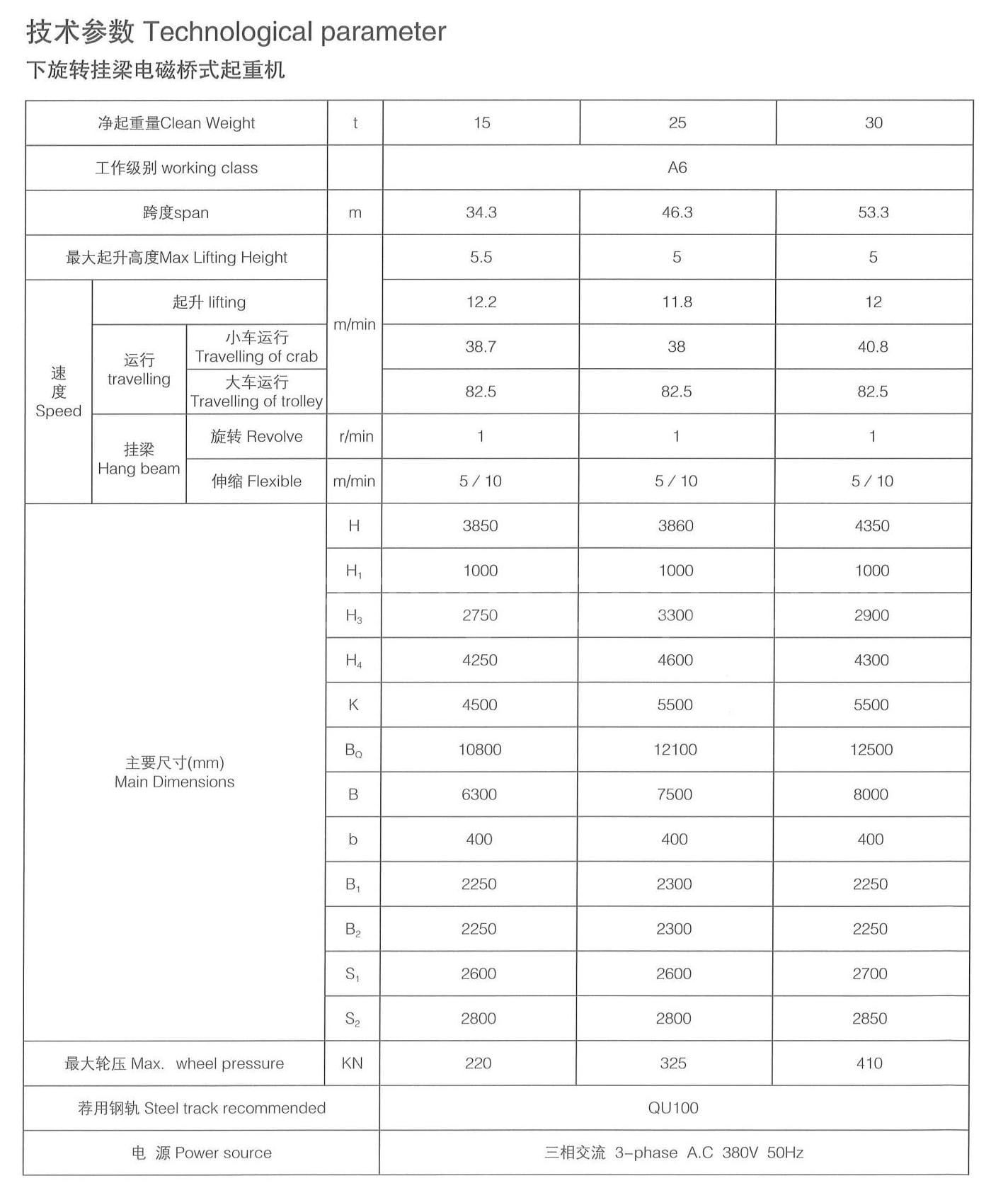

Electromagnetic overhead crane na may umiikot na lifting beam

Ang crane na ito ay may umiikot na electromagnetic lifting beam, na idinisenyo para sa panloob o panlabas na mga fixed span sa mga gilingan ng bakal, shipyards, port, storage yard, at warehouse. Ito ay ginagamit para sa pagkarga, pagbabawas, at paghawak ng mga materyales tulad ng mga bakal na plato, mga seksyon, at mga coil. Ito ay partikular na angkop para sa pag-angat at pahalang na pag-ikot ng mga item ng iba't ibang mga detalye, na nagbibigay-daan para sa mas kaunting pagsasaayos ng electromagnetic na puwersa batay sa mga detalye ng materyal (tulad ng kapal, haba, at dami) at timbang. Ayon sa mga kinakailangan ng user, maaari itong magsama ng mga feature gaya ng adjustable speed para sa iba't ibang mekanismo (1:10 o mas mataas), overload na proteksyon at mga alarm, remote control, PLC control na may fault detection, at mga system para sa pagpapakita, pagre-record, at pag-print. (Ang mga sumusunod na parameter ay para sa panloob na paggamit.)

Pagtutukoy

Electromagnetic overhead crane na may rotating lifting beam diagram

Electromagnetic overhead crane na may rotating lifting beam parameter

FAQ

- Ano ang iba't ibang uri ng electromagnetic overhead cranes?

Ito ay maaaring uriin sa istruktura sa mga electromagnetic overhead crane at electromagnetic overhead crane na may lifting beam. - Ano ang mga mga pakinabang ng electromagnetic overhead cranes?

Ang electromagnetic overhead crane ay nag-aalok ng mabilis at mahusay na solusyon para sa lahat ng mga sitwasyon sa trabaho na nangangailangan ng paghawak ng bakal. Maaari itong suportahan ang mas malalaking load, na nagpapataas ng kahusayan sa trabaho. Bukod pa rito, nagtatampok ito ng mas mataas na kaligtasan na may power-off magnetic retention function. - Electromagnetic overhead crane kung paano ito gumagana?

Gumagamit sila ng magnetic field na nabuo ng kasalukuyang dumadaan sa coil sa paligid ng magnet. Kapag naka-on ang kasalukuyang, inaakit ng electromagnet ang mga bagay na bakal, na dinadala sa itinalagang lokasyon. Ang magnetism ay nawawala kapag ang kasalukuyang ay pinatay, at ang mga bagay na bakal ay inilabas. - Ano ang mga gamit ng electromagnetic overhead cranes?

Mga istasyon ng pag-recycle ng bakal, mga lugar ng imbakan ng scrap ng bakal, mga gilingan ng bakal, mga pandayan, mga shipyard, mga stockyard ng bakal, atbp.

Mga serbisyo

Ang Kuangshan Crane ay may higit sa 20 taon ng malawak na karanasan sa paggawa at pag-export ng mga electromagnetic overhead crane na may lifting beam, na nag-aalok ng mga kinakailangang ekstrang bahagi at propesyonal na pag-install at mga serbisyo sa paggabay sa pagpapanatili para sa lahat ng electromagnetic overhead crane na may lifting beam.

- Mga ekstrang bahagi

Ihahanda namin ang mga kinakailangang ekstrang bahagi para sa iyong electromagnetic overhead crane na may mga lifting beam upang ang anumang nasira o nawawalang mga bahagi ay mapalitan kaagad, binabawasan ang downtime ng maintenance at pagpapabuti ng kahusayan sa produksyon. - Pag-install

Nagbibigay kami ng mga detalyadong pamamaraan sa pag-install ng video, at kung kinakailangan, maaari rin kaming mag-alok ng malayuang gabay sa video. - Pagpapanatili

Nagbibigay kami ng mga detalyadong tagubilin sa pagpapanatili at nag-aalok ng mga libreng serbisyo sa konsultasyon para sa anumang mga isyu na maaaring lumabas sa panahon ng paggamit ng crane.

Henan Kuangshan Crane

Ang mga drawing na ginamit ng Henan Kuangshan Crane Co., Ltd. ay ang lahat ng pinakabagong mga disenyo batay sa mga order at na-optimize sa pamamagitan ng computer-aided na disenyo, na nagreresulta sa isang mas makatwirang istraktura. Ang lahat ng mga disenyo ng pagguhit ay sumusunod sa pinakabagong pambansang pamantayan na nakahanay sa mga internasyonal na pamantayan, na kumakatawan sa pinakabagong disenyo ng istruktura at advanced na antas ng mga produktong domestic lifting. Ang kagamitan sa produksyon ng Henan Kuangshan ay advanced, at ang kagamitan sa inspeksyon nito ay komprehensibo, na tinitiyak ang kalidad ng mga crane sa bawat aspeto.

Kagamitan sa Produksyon

Kasama sa plano ang pag-install ng 22 intelligent na linya ng produksyon, na may mga antas ng automation na umaabot sa mahigit 85% sa buong proseso ng produksyon.

Kagamitan sa Inspeksyon

Mayroon kaming matatag na sistema ng pagtiyak sa kalidad ng produkto, isang komprehensibong departamento ng inspeksyon ng kalidad, at mga kwalipikadong tauhan ng kontrol sa kalidad. Nagtataglay kami ng mahigit 100 iba't ibang instrumento sa inspeksyon at pagsubok at mga pang-eksperimentong device, ang ilan sa mga ito ay nasa nangungunang antas sa loob ng bansa at advanced sa buong mundo.

Makipag-ugnayan

- Libre at mabilis na quote para sa produkto.

- Ibigay sa iyo ang aming katalogo ng produkto.

- Ang iyong lokal na proyekto ng crane mula sa aming kumpanya.

- Maging aming ahente at kumita ng komisyon.

- Anumang mga katanungan, makipag-ugnayan sa amin.