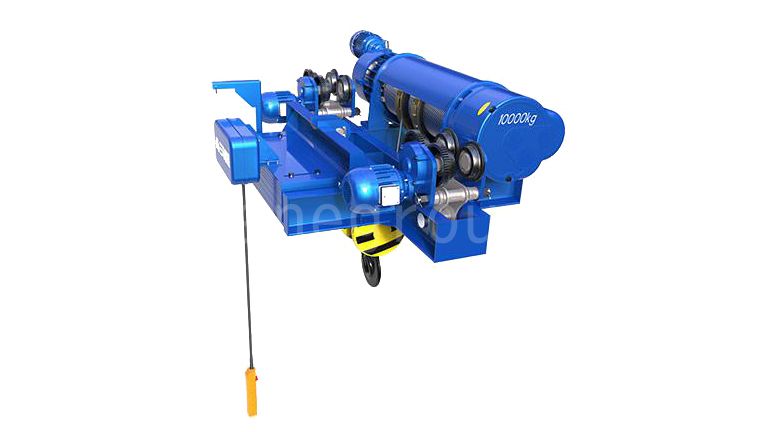

Low-headroom Electric Hoist

Advantage

Low-headroom Electric Hoist is mainly set on the single girder overhead cranes to lift cargoes. Because of its special placement in the girder, it can lift more 200~500mm than normal hoists. Therefore, it is widely used in the places which height is limited.

Low-headroom Electric Hoist is mainly set on the single girder overhead cranes to lift cargoes. Because of its special placement in the girder, it can lift more 200~500mm than normal hoists. Therefore, it is widely used in the places which height is limited.

Accessories

Wire rope Electric Hoist is assembled by several parts: Hoisting Gear Box, Hoisting Motor with brake, Rope Drum, Electric Control Panel and Traveling Trolley. All these units are separately accessible and promptly disassembled cost and stopped.

Motor: Hoist Motor is a taper type rotor motor with braking, it is made by Nanjing special motor factory, it is of the best quality motors, it has bigger torque, so it can be adapted to moving frequently, the Maximum torque is 2.4-3 times than the rated torque.

Gear Box: Hoist Gear Box has specially treated gears for high wear resistance. Each Geared Shaft assembly is supported on ball or roller bearings, to ensure smooth, low-friction operation.

Wire Rope: Hoisting ropes comply with the exporting standards. The leading rope taken by the Drum does not slip sideways when slack. The factor of safety, on the nominal breaking strength of the rope is six.

Rope Drum: Grooved hoist Drum, seamless pipe of adequate length to be wounded in one layer and to provide proper support for the rope to minimize abrasive wear is provided. Drum Shaft resolves on Ball Bearings for ensuring smooth running.

Electric apparatus controlling system: Model CD1 and MD1 hoist is composed of the contactor box, controlling switch, cut-off limiter, the working voltage of controlling switch is 380V,36V or 24V(safety voltage).

Rope Guide: Rope Guide is in two halves, ensuring easy accessibility. It encircles the Drum completely so that the rope may not uncoil even when the Hoist is in unloaded condition. The rope guides of our company is thickened and dilated, so that it is not easy to be damaged.

Hook: The Hook Block is tested to 150 % of full load before assembly. The rope sheaves are fully guarded with protective steel casting. All sheaves rotate on ball bearing the pulley is thicken and dilated than domestic common pulley.