- UDSTYR

- specielle kraner

- Industri kran

- Hejse- og spilvogn

-

KRAN Spreder

-

Kran Elektromagnetiske Løftemagneter

-

Løfteelektromagnet til drejning og sidehængt

-

Løfteelektromagnet til tyk plade

-

Specialiseret elektromagnet til løft af stålplader

-

Løfteelektromagneter til løft af stålplader

-

Løfteelektromagnet til tunge skinner og profileret stål

-

Løfteelektromagnet til højhastigheds Wier (spolet stang)

-

Løfteelektromagnet til armeringsjern og stålrør

-

Løfteelektromagnet til bundtet armeringsjern og profileret stål

-

Løfteelektromagnet til bjælke, bjælke og plade

-

Løfteelektromagnet til stålrester

-

- Kranspreder

- Kranløftetænger og -klemmer

-

Kran Elektromagnetiske Løftemagneter

- KRANDELE

- Overfør kurv

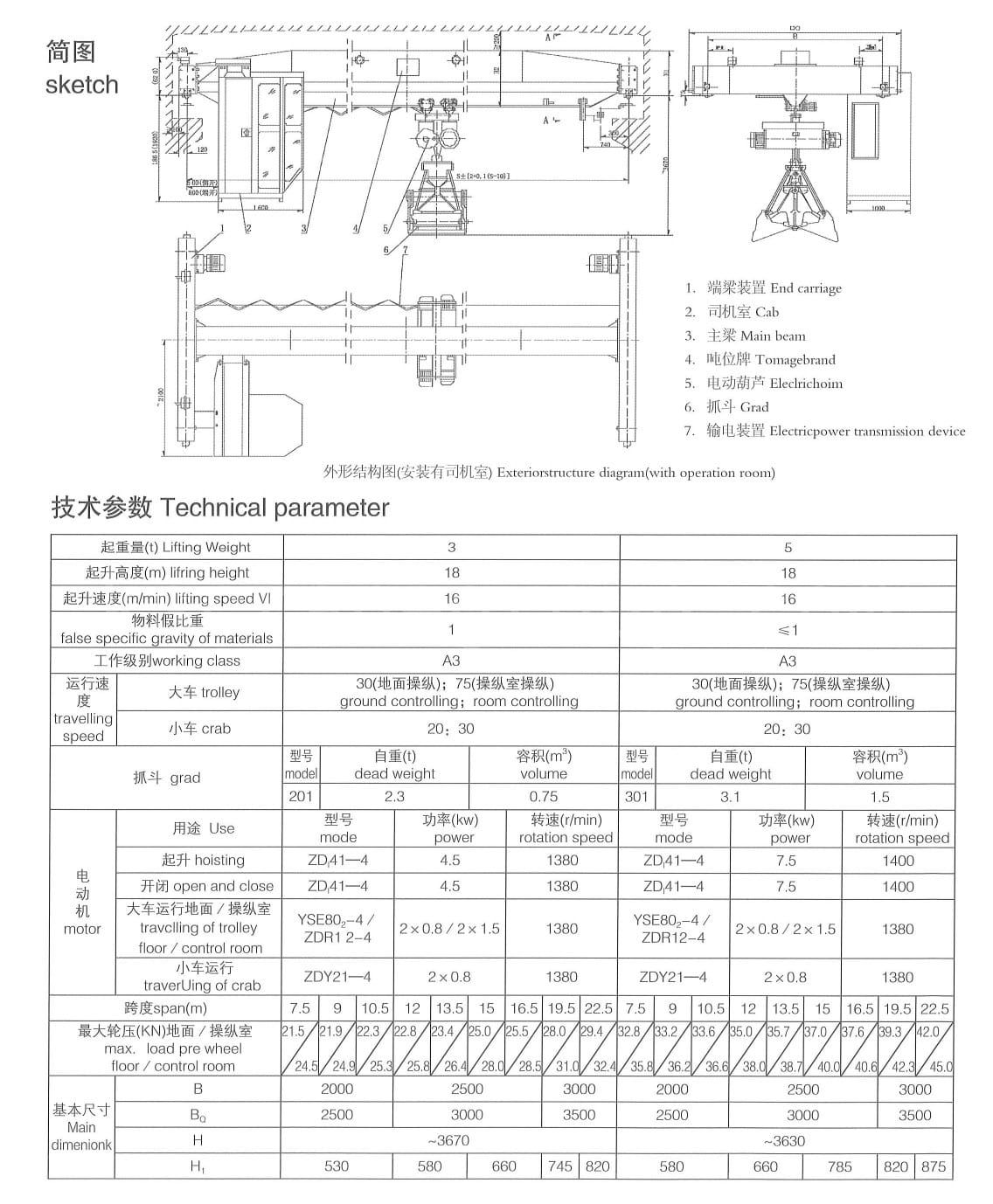

LDZ enkeltbjælke gribekran: Kraftige løsninger til håndtering af bulkmateriale

LDZ enkeltbjælke griber traverskran er stort set den samme som LD elektriske enkeltbjælke traverskran, kun fat i spanden mekanismen er anderledes. Kranen er udstyret med en gribevogn og er velegnet til håndtering af næsten alle løse og bulkmaterialer såsom affald, industrimaterialer og sand. Løftekapaciteten på traverskranen varierer fra 2 til 10 tons, og arbejderklassen er A4. Denne kran kan ikke bruges i brandfarlige, eksplosive eller ætsende miljøer. Den er ideel til løft i minedrift, affaldsbehandlingsanlæg, stålværker og kraftværker.

LDZ enkeltbjælke gribebrokran Struktur

- Gribebrokraner er sammensat af hoveddele såsom bro, gribevogn, kranbetjeningsmekanisme og elektrisk kontrolsystem.

- Bro: Denne metalstruktur består af hoveddrager og endedrager. Hoveddrageren vedtager kassestruktur sammensat af U-kanal og I-strålegruppe.

- Kranvogn: løft af gods samt enheden kørende vandret langs broen. To sæt elektriske hejseværker er generelt installeret på vognen, et sæt til at løfte varer op og ned, og det andet sæt til at åbne og lukke griberen. Den elektriske hejs er hovedsageligt opdelt i to kategorier: wirehejs og håndtrukket hejs, og førstnævnte er mere udbredt.

- Kranløbsmekanisme: driver hele kranen til at bevæge sig frem og tilbage langs banebjælken. Køremekanismen vedtager separat køretilstand, som afsluttes af konisk rotor med bremsemotor eller elektromagnetisk bremse solid rotormotor. Kørehastigheden kan være 20, 30, 45 m/min.

- Elektrisk styresystem: Det er enheden, der leverer elektricitet til kranens funktion. Det elektriske systemdesign bør tage hensyn til nogle forhold såsom pålidelighed, holdbarhed og sikkerhedsforanstaltninger ved løft.

Specifikationer for en enkelt drager overheadkran

Enkeltstrålet gribebrokran fjernbjælke intern samlingsrobotsvejselinje

- Sammenlignet med manuelt arbejde er de svejsninger, der dannes af robotten, fremragende i form, svejsebredden er ensartet, overfladen er flad, og manglen er stort set nul.

- På grund af svejsningens ensartede bredde reduceres skaden forårsaget af spændingskoncentrationen på svejsningen kraftigt, og den gennemsnitlige svejsehøjde er højere end den kunstige svejsning, hvilket i høj grad forbedrer produktets styrke.

Sag

Enkeltbjælke gribekraner til bryggerier

Kontakt os

- Gratis og hurtigt tilbud på produktet.

- Giv dig vores produktkatalog.

- Dine lokale kranprojekter fra vores firma.

- Bliv vores agent og tjen kommission.

- Eventuelle spørgsmål, kontakt os.