- معدات

- رافعات خاصة

- صناعة كرين

- عربة الرفع والونش

-

ناشرة الرافعة

-

مغناطيسات الرفع الكهرومغناطيسية للرافعات

-

رفع المغناطيس الكهربائي للدوران والتعليق الجانبي

-

رفع المغناطيس الكهربائي للوحة السميكة

-

مغناطيس كهربائي متخصص لرفع الألواح الفولاذية

-

رفع المغناطيسات الكهربائية لرفع ألواح الصلب

-

رفع المغناطيس الكهربائي للسكك الحديدية الثقيلة والفولاذ المشكل

-

رفع المغناطيس الكهربائي للأسلاك عالية السرعة (القضيب الملفوف)

-

رفع المغناطيس الكهربائي لحديد التسليح وأنابيب الصلب

-

رفع المغناطيس الكهربائي لقضبان التسليح المجمعة والفولاذ المشكل

-

رفع المغناطيس الكهربائي للبليت والعارضة والبلاطة

-

رفع المغناطيس الكهربائي لقصاصات الصلب

-

- ناشرة الرافعة

- ملقطات ومشابك رفع الرافعات

-

مغناطيسات الرفع الكهرومغناطيسية للرافعات

- أجزاء الرافعة

- عربة نقل

رافعة علوية بعارضة واحدة عادية مقابل رافعة علوية بعارضة واحدة من نوع LD Ordinary مقابل رافعة علوية بعارضة واحدة من نوع LDP Offset: اعثر على العارضة المثالية التي تلبي احتياجات التصنيع الدقيق لديك

التاريخ: 27 ديسمبر 2024

جدول المحتويات

في المشاريع الصناعية، يعد اختيار معدات الرفع المناسبة أمرًا بالغ الأهمية لكفاءة الإنتاج وجودة المنتج. وينطبق هذا بشكل خاص في السيناريوهات التي تتطلب تصنيعًا دقيقًا ومعالجة عالية الدقة، حيث تكون قابلية تطبيق المعدات واستقرارها أمرًا بالغ الأهمية. اليوم، سنعرض مشروعًا حقيقيًا من ورشة العمل رقم 3 لمصنع تصنيع قوالب دقيقة لإظهار أداء رافعة علوية ذات عارضة واحدة تعمل من أعلى طراز LD و رافعة علوية ذات عارضة واحدة من نوع LDP تحت احتياجات مختلفة. سواء كان الأمر يتعلق بتحسين كفاءة الإنتاج أو تلبية المتطلبات الصارمة لدقة قطعة العمل، فإننا ملتزمون بإيجاد الحل الأمثل لعملائنا.

1. خلفية المشروع ومتطلبات العملاء

العميل هو مصنع لتصنيع القوالب الدقيقة. ورشة العمل رقم 3 التي تم بناؤها حديثًا مسؤولة بشكل أساسي عن مهام إنتاج الآلات عالية الجودة باستخدام الحاسب الآلي. تم تقسيم الورشة إلى منطقتين جنوبية وشمالية، مع وجود رافعة علوية مزدوجة العارضة QD10t-S10.5m مثبتة بالفعل في المنطقة الجنوبية لأعمال تجميع القوالب الكبيرة. ومع ذلك، نظرًا للنمو المتوقع في عبء العمل، كان العميل قلقًا من أن الرافعة الحالية قد لا تلبي الاحتياجات التشغيلية المتزامنة في كلتا المنطقتين خلال مواسم الذروة.

في البداية، أراد العميل تعديل الوضع التشغيلي للمعدات الحالية لتوفير تكاليف الاستثمار. ومع ذلك، بعد إجراء بحث في الموقع، وجدنا أن هذا من شأنه أن يؤثر سلبًا على كفاءة الإنتاج. بالتعاون مع فريق الإنتاج الخاص بالعميل، درسنا كل عملية تشغيلية بالتفصيل وأجرينا تحليلات محاكاة مصممة خصيصًا لاحتياجات الرفع المختلفة للمناطق الجنوبية والشمالية. ومن خلال هذا الاستكشاف المتعمق، حددنا أوجه القصور في الخطة الحالية وأوصينا في النهاية بإضافة معدات رفع جديدة في المنطقة الشمالية لضمان استقرار الإنتاج خلال فترات الذروة. لم يكن هدفنا مجرد توفير رافعة مناسبة ولكن تقديم عملية إنتاج مُحسَّنة وحل شامل لتحسين الكفاءة.

2. من المتطلبات إلى الحلول: التعاون مع العميل

2.1 الاختيار الأولي للرافعة العلوية ذات العارضة الواحدة LD:

خلال المناقشة الأولية، أبدى العميل اهتمامه برافعة علوية ذات عارضة واحدة من LD. تشتهر هذه الرافعة بفعاليتها العالية من حيث التكلفة وبنيتها البسيطة، حيث يلبي ارتفاع الرفع التقليدي معظم السيناريوهات الصناعية. وبالتعاون مع العميل، استكشفنا ميزات تصميم رافعة علوية ذات عارضة واحدة من LD وتطبيقها المحتمل في المنطقة الشمالية. ونظرًا للنهج المراعي للميزانية، بدا اختيار رافعة علوية ذات عارضة واحدة من LD خيارًا اقتصاديًا.

2.2 إعادة تقييم متطلبات ارتفاع الرفع:

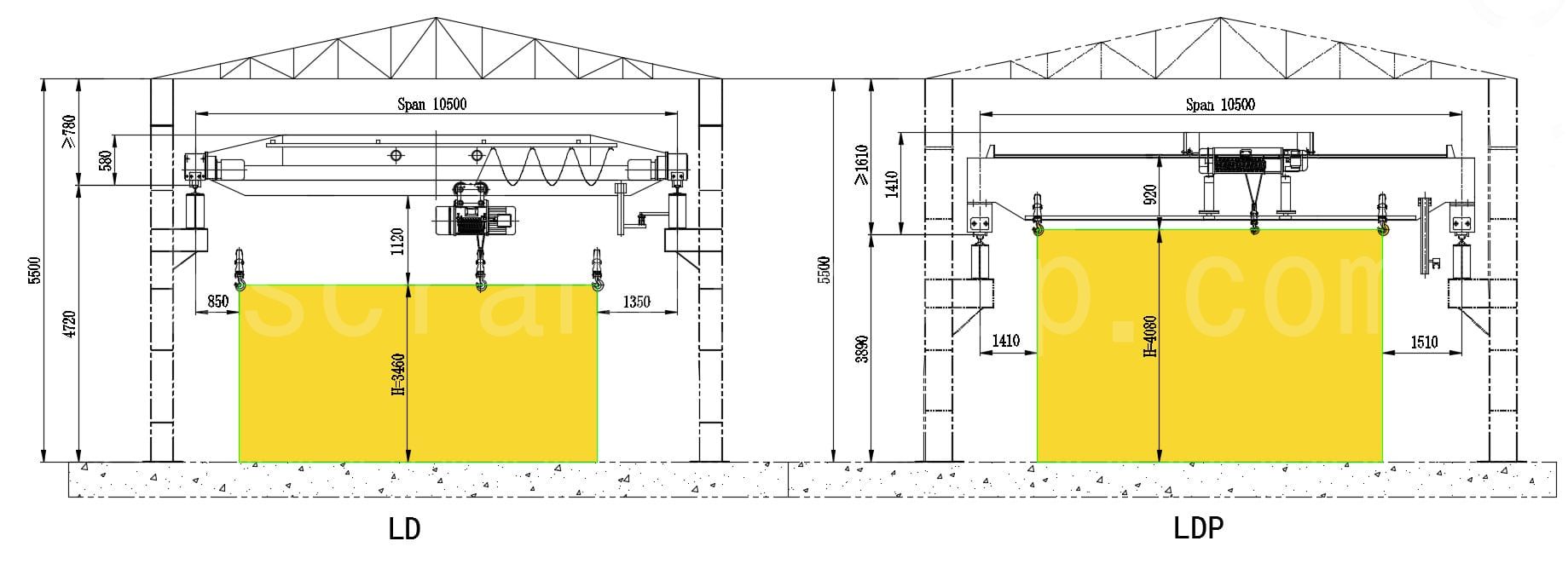

ومع ذلك، في مناقشات أخرى، علمنا أن العميل لديه مطالب عالية لارتفاع الرفع في مركز التصنيع بالمنطقة الشمالية. وكشف تقييم ثانٍ للموقع أن متطلبات ارتفاع الرفع الفعلية يجب أن تكون 4 أمتار على الأقل لتلبية احتياجات الإنتاج. لم تتمكن الرافعة العلوية ذات العارضة الواحدة من LD من تحقيق ارتفاع رفع يبلغ 3.46 مترًا فقط. وبالتالي، أدركنا أن الرافعة العلوية ذات العارضة الواحدة من LD لا يمكنها تلبية متطلبات الارتفاع بالكامل.

2.3 الحل النهائي: المطابقة الدقيقة مع رافعة علوية أحادية العارضة ذات إزاحة LDP:

بناءً على هذه الاعتبارات، أوصينا برافعة علوية أحادية العارضة 5 طن-S10.5 متر من نوع LDP. يتميز هذا الطراز بتصميم جانبي فريد يزيد من ارتفاع الرفع (حتى 4.08 متر) في الورش ذات الارتفاع الصافي المحدود. لمساعدة العميل على فهم أفضل، قمنا بترتيب فريق الهندسة لدينا لتصميم الرسومات الأولية وشرح معايير الأداء والسيناريوهات القابلة للتطبيق ومزايا رافعة علوية أحادية العارضة من نوع LDP.

لقد أثار نظام التحكم في تحويل التردد لرافعة الجسر العلوية ذات العارضة الواحدة ذات الإزاحة LDP إعجاب العميل بشكل خاص، حيث يوفر التحكم في السرعة بدون خطوات، وانخفاض الضوضاء، والتشغيل المستقر والموثوق. أثناء عمليات التثبيت، يتيح النظام رفعًا سلسًا وتحديد موضع دقيق لقطع العمل. وقد اكتسبت التفسيرات المهنية والعروض التوضيحية الصبورة التي قدمها الموظفون الفنيون ثقة العميل، مما أدى في النهاية إلى الإجماع على اختيار المعدات.

3. مقارنة المعدات وتنفيذ المشروع

في هذا المشروع، قدمنا مقارنة تفصيلية للمعايير الفنية والسيناريوهات القابلة للتطبيق لرافعة علوية ذات عارضة واحدة LD ورافعة علوية ذات عارضة واحدة منحرفة LDP، مما يضمن حصول العميل على فهم واضح لمزاياها:

3.1 نظرة عامة على المنتج

رافعة علوية ذات عارضة واحدة LD:

الرافعة الجسرية ذات العارضة الواحدة LD، المستخدمة مع الرافعات الكهربائية من النوع CD1، هي جهاز رفع ورشة عمل يستخدم على نطاق واسع في التصنيع والتجميع والإصلاح والمستودعات وغيرها من الإعدادات. إنها أداة أساسية للمؤسسات الصناعية الحديثة التي تهدف إلى ميكنة وأتمتة عمليات الإنتاج وتقليل كثافة العمالة وتحسين الإنتاجية.

رافعة علوية ذات عارضة واحدة ذات إزاحة LDP:

توفر الرافعة العلوية ذات العارضة الواحدة ذات الإزاحة LDP، بهيكلها الزاوي، استغلالًا أفضل لمساحة الارتفاع مقارنة بالرافعة العلوية ذات العارضة الواحدة LD. تُستخدم عادةً في المصانع حيث يكون ارتفاع المسار منخفضًا ولكن الارتفاع الصافي الواضح بين أعلى المسار وأدنى نقطة في المبنى كبير نسبيًا. يزيد هذا الهيكل بشكل فعال من ارتفاع رفع الرافعة مع تحسين مساحة الورشة.

3.2 الميزات الهيكلية

رافعة علوية ذات عارضة واحدة LD:

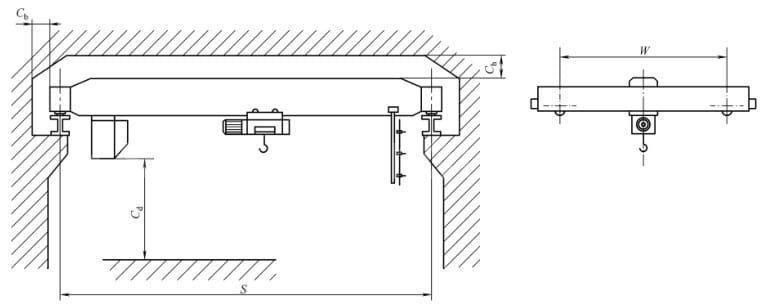

تستخدم الرافعة العلوية ذات العارضة الواحدة من LD عارضة رئيسية واحدة، مما يجعلها مناسبة لاحتياجات الرفع العامة. تتميز بهيكل عام بسيط وسهل التركيب. يضمن تصميم عربة الرفع الكهربائية التقليدية التشغيل المستقر. تتكون الرافعة العلوية ذات العارضة الواحدة من LD بشكل أساسي من العارضة الرئيسية والعوارض الطرفية والرافعة الكهربائية وآلية حركة الرافعة والمعدات الكهربائية.

- العارضة الرئيسية: عارضة على شكل حرف I أو عارضة صندوقية ذات حافة مائلة مناسبة لعجلات عربة الرفع التقليدية.

- عوارض النهاية: تتضمن محرك التشغيل، والمخفض، والعجلات، ومكونات المخزن المؤقت.

- المعدات الكهربائية: مزود طاقة ثلاثي الطور (50 هرتز أو 60 هرتز، 220 فولت - 660 فولت)، مع أسلاك انزلاقية أمان وعربات كابلات.

- رافعة كهربائية: مقترنة مع الرافعات الكهربائية ذات الحبال السلكية من النوع CD1 أو MD1.

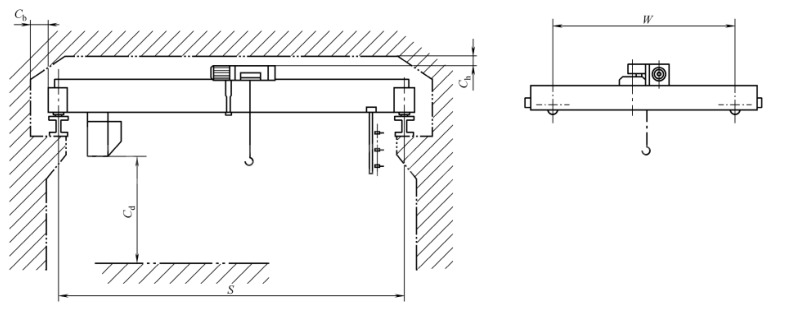

رافعة علوية ذات عارضة واحدة ذات إزاحة LDP:

تم إزاحة العارضة الرئيسية لرافعة الجسر العلوية ذات العارضة الواحدة المزاحة LDP إلى جانب واحد من العارضة النهائية، مما يجعل هذا التصميم أكثر ملاءمة للمواقف ذات ارتفاع المبنى المحدود، والاستفادة بشكل فعال من المساحة المتاحة. تم تحسين تصميم العربة للهيكل الجانبي، مما يسمح لها بالعمل بمرونة في المساحات الضيقة. تتكون الرافعة الجسرية ذات العارضة الواحدة المزاحة الكهربائية LDP بشكل أساسي من العارضة الرئيسية والعوارض النهائية والعربة المائلة وآلية حركة الرافعة والمعدات الكهربائية.

- العارضة الرئيسية: عارضة صندوقية من صفائح الفولاذ الملحومة.

- عوارض النهاية: تتضمن محرك التشغيل، والمخفض، والعجلات، ومكونات المخزن المؤقت.

- المعدات الكهربائية: مماثل لنموذج LD.

- رافعة كهربائية: مثبتة فوق العربة الزاوية على جانب واحد من العارضة الرئيسية.

3.3 مقارنة المعلمات الفنية

مقارنة المعلمات لهذه الحالة:

| معامل | نموذج LD | نموذج الحزب الليبرالي الديمقراطي |

|---|---|---|

| ارتفاع المصنع الصافي (مم) | 5500 | 5500 |

| ارتفاع سكة الرافعة (مم) | 4720 | 3890 |

| المساحة الصافية من السكة إلى السقف (مم) | ≥780 | ≥1610 |

| ارتفاع الرفع الفعال (مم) | 3460 | 4080 |

| حد خطاف الرفع (مم) | 1120 | 920 |

| حدود الخطاف لليسار/اليمين (مم) | 850/1350 | 1410/1510 |

| الوزن الإجمالي (كجم) | 2720 | 3760 |

| حمولة العجلة (كيلو نيوتن) | 35 | 38 |

| سعر المعدات (10 آلاف يوان صيني) | 2.32 | 3.62 |

إن اختيار المعدات لدينا يعطي الأولوية لاحتياجات العميل الإنتاجية، من خلال توفير مستندات فنية مفصلة وتحليلات التكلفة والفائدة. كما أن كل مقارنة دقيقة وتواصل شفاف يضمن أن يشعر العميل بتفانينا في المشروع.

4. نتائج المشروع وردود أفعال العملاء:

بعد التنفيذ، قمنا بمراقبة أداء المعدات عن كثب. بعد نشر رافعة جسرية أحادية العارضة ذات إزاحة LDP، تحسنت كفاءة الإنتاج في المنطقة الشمالية بشكل كبير، وخاصة في مهام تحديد المواقع الدقيقة، حيث تفوق نظام التحكم في تحويل التردد. ذكر العميل عدة مرات، "أصبحت الورشة الآن منظمة بشكل جيد، وتعمل الرافعة بسلاسة، وخاصة أثناء التشغيل الدقيق، حيث يكون تعزيز الكفاءة واضحًا". مثل هذه الملاحظات الصادقة هي أفضل تقدير لجهودنا. لقد أسسنا أيضًا علاقة تعاون طويلة الأمد مع العميل، حيث نقدم الدعم المستمر للصيانة والترقيات الفنية.

5. الخاتمة

في التصنيع الدقيق، يمكن أن يؤدي اختيار معدات الرفع المناسبة إلى تحسين كفاءة الإنتاج وجودة المنتج بشكل كبير. تعد الرافعة العلوية ذات العارضة الواحدة LD مثالية لسيناريوهات الرفع القياسية التي تراعي الميزانية مع متطلبات ارتفاع أقل. من ناحية أخرى، تعد الرافعة العلوية ذات العارضة الواحدة المزاحة LDP الخيار الأمثل للسيناريوهات التي تتطلب ارتفاع رفع أكبر وتحكمًا دقيقًا. لكل مشروع، نستمع بعناية إلى احتياجات العملاء ونقدم حلولاً مخصصة. بغض النظر عن مدى تفرد مشروعك، فنحن على استعداد لاستكشافه معك، والعثور على المعدات الأكثر ملاءمة، ومساعدتك في تحقيق أهداف الإنتاج الخاصة بك.

هل تحب ما نفعله؟أنشرها

العلامات: رافعة علوية ذات عارضة واحدة LD,رافعة علوية ذات عارضة واحدة من نوع LDP